Freezing apparatus

A technology of freezing device and feeding device, which is applied to household refrigeration devices, coolers, lighting and heating equipment, etc., can solve the problems of high assembly cost, unfavorable reciprocating vibration, large vibration acceleration, etc., and is conducive to popularization and application. The effect of high vibration acceleration and high vibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

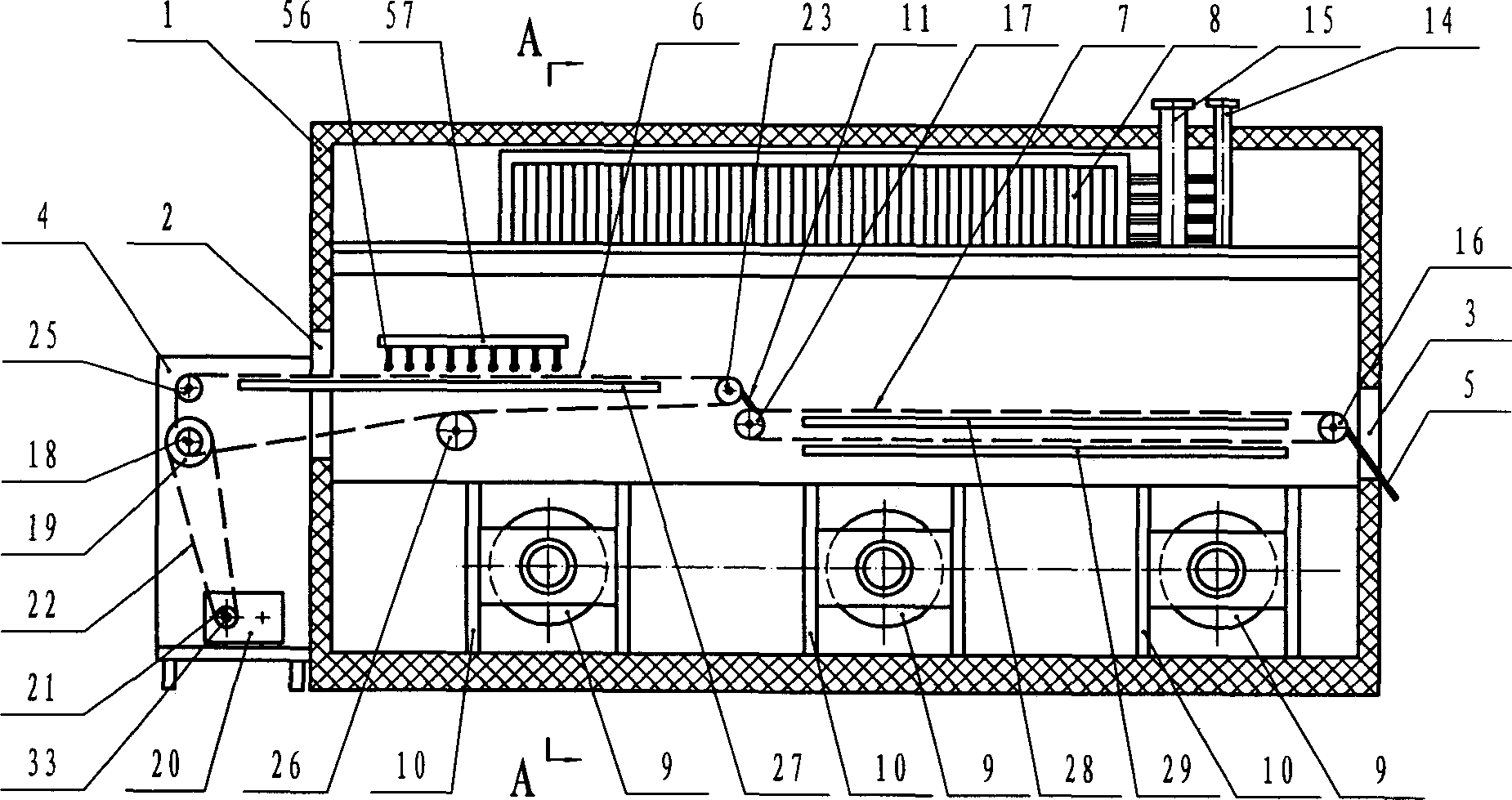

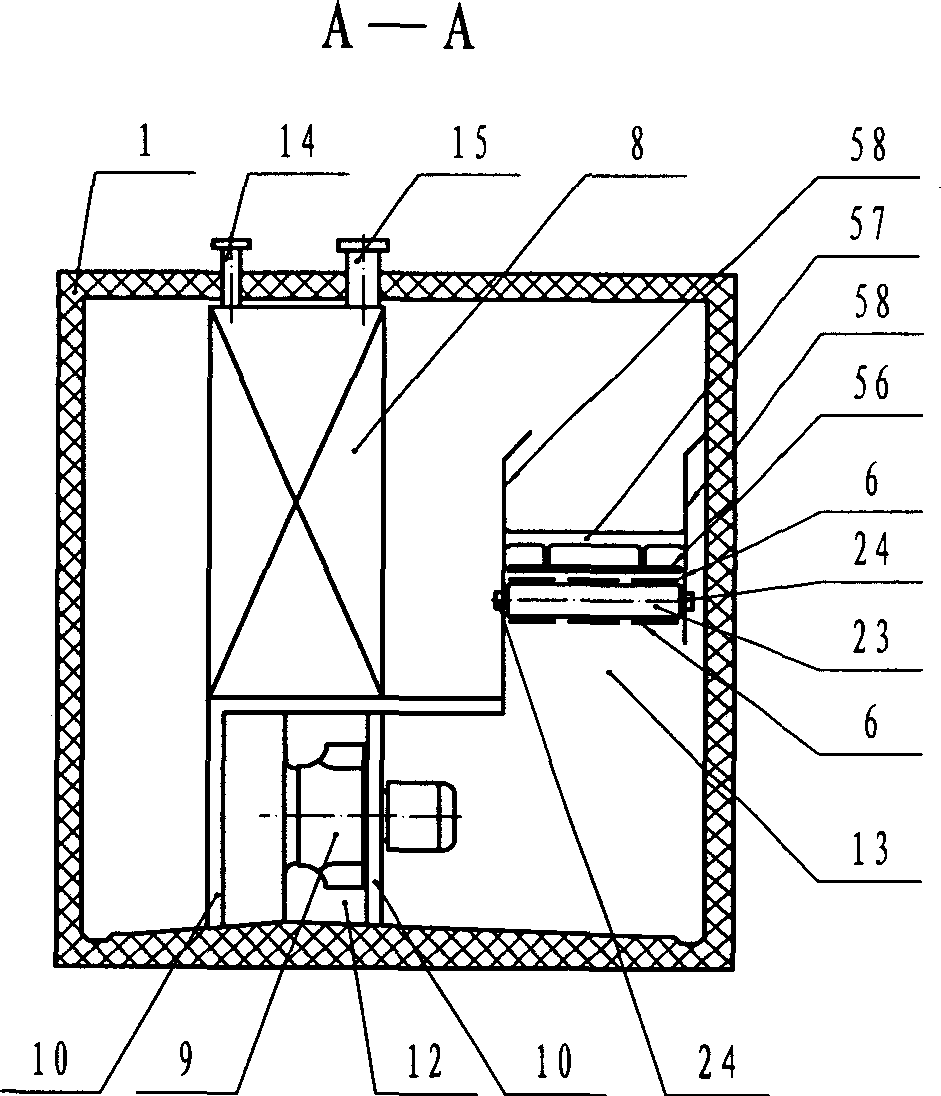

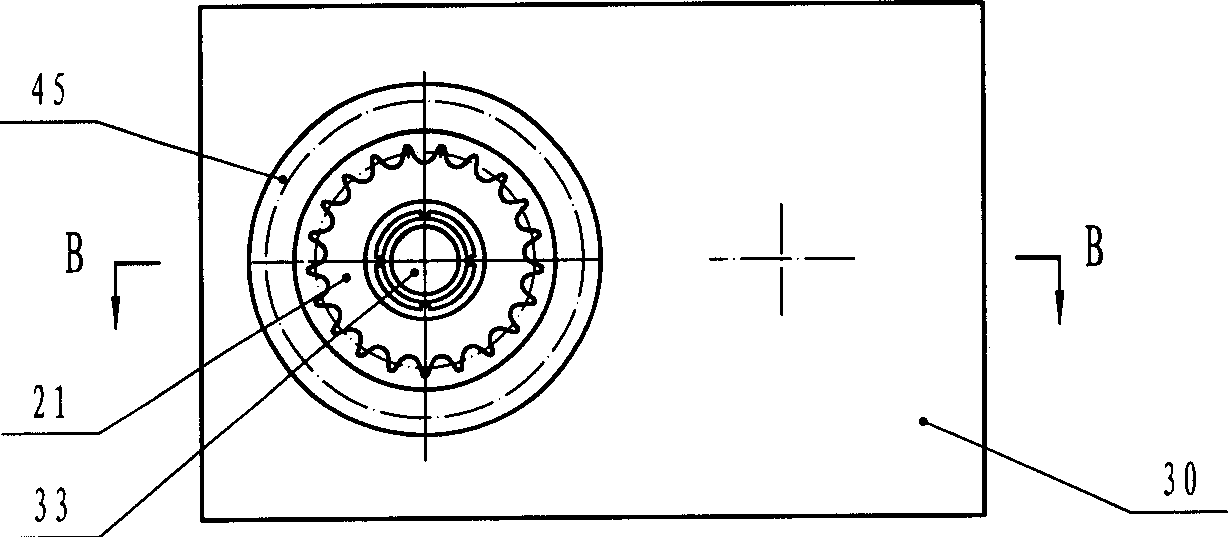

[0022] freezer (see figure 1 ) includes a thermal insulation box 1, a feed mechanism 4 and a discharge mechanism 5 respectively placed in the feed port 2 and the discharge port 3 of the thermal insulation box 1, and the first section of circulating conveying mesh belt installed in the thermal insulation box 1 6 and the second section of circulating conveying mesh belt 7, the cooling fan formed by the evaporator 8 and the fan unit 9 located in the heat insulation box 1, the bracket 10 connecting the evaporator 8 and the fan unit 9, and installed on the first section of circulating conveying mesh belt 6 and the scraper 11 between the second section of circulating conveying mesh belt 7. The air outlet 12 of the cooling fan communicates with the air collecting chamber 13 below the circulating conveying mesh belt (see figure 2 ), the liquid supply pipe 14 and the gas return pipe 15 of the evaporator are connected to the refrigeration unit respectively. The driving shaft roller 1...

Embodiment 2

[0025] The difference with Embodiment 1 is: the output shaft of the feed drive electric speed reducer 32 is fixedly equipped with a gear 48, and the gear 48 is meshed with the iron ring gear 36 for transmission (see Figure 6 ), drive the iron stopper 37 on the iron stop ring gear 36 to make forward low-speed rotary motion.

Embodiment 3

[0027] The difference with Embodiment 1 or 2 is: the output shaft 34 of the reciprocating vibration electric reducer 31 is fixedly connected with the output shaft 33 of the mechanically combined reciprocating vibration feeding device 20 with a shaft coupling 49 (see Figure 7 ), driving the output shaft 33 for reciprocating rotary motion, and 50 is a bearing for connecting the output shaft 33 with the frame 30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com