Drive unit for generating an oscillatory motion for electrical small-scale units

A drive unit, oscillating motion technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problem of strong vibration of the motor shell and toothbrush, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

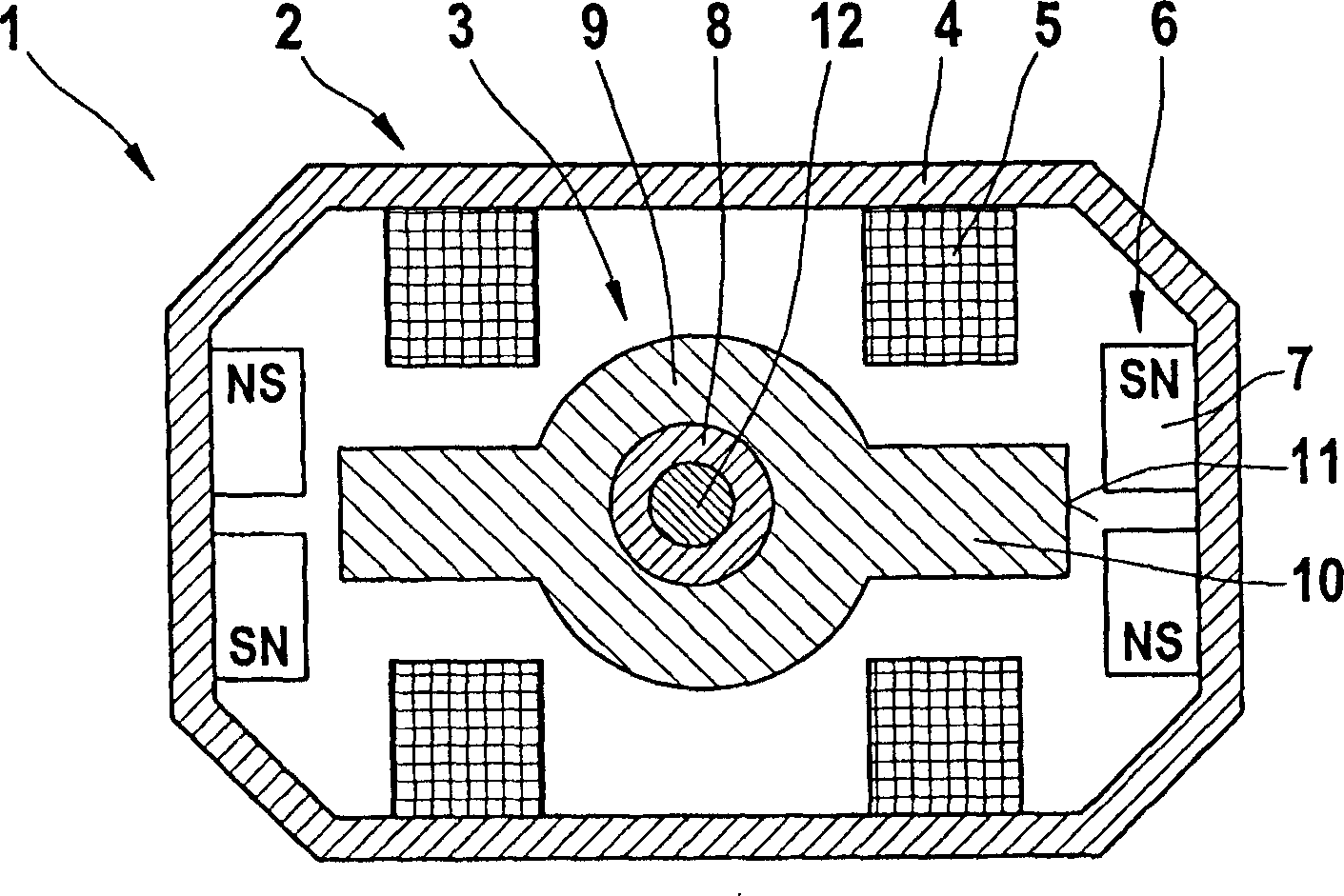

[0025] figure 1 An exemplary embodiment of a drive unit 1 constructed according to the invention is shown in a very schematic sectional view. As main functional components, the drive unit 1 comprises a stationary stator 2 and a rotor 3 arranged rotatably relative to the stator 2 about the longitudinal axis of the drive unit 1 . The stator 2 has a housing 4 made of a magnetizable material, two coils 5 connected in series, for example, and two magnetic devices 6 each having two permanent magnets 7 . Two coils 5 are arranged parallel to each other, wherein the axes of the two coils 5 coincide with each other and in figure 1 represents the mid-level distribution of . The magnetic devices 6 are arranged opposite each other on opposite sides of the housing 4 , wherein the individual permanent magnets 7 of the magnetic devices 6 are each positioned symmetrically with antiparallel polarity side by side with respect to the axis of the coil 5 . In this case, a small distance is alway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com