Universal space self-potential stiff mill

A self-aligning, high-rigidity technology, used in metal rolling stands, metal rolling mill stands, metal rolling, etc., can solve problems such as inability to

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

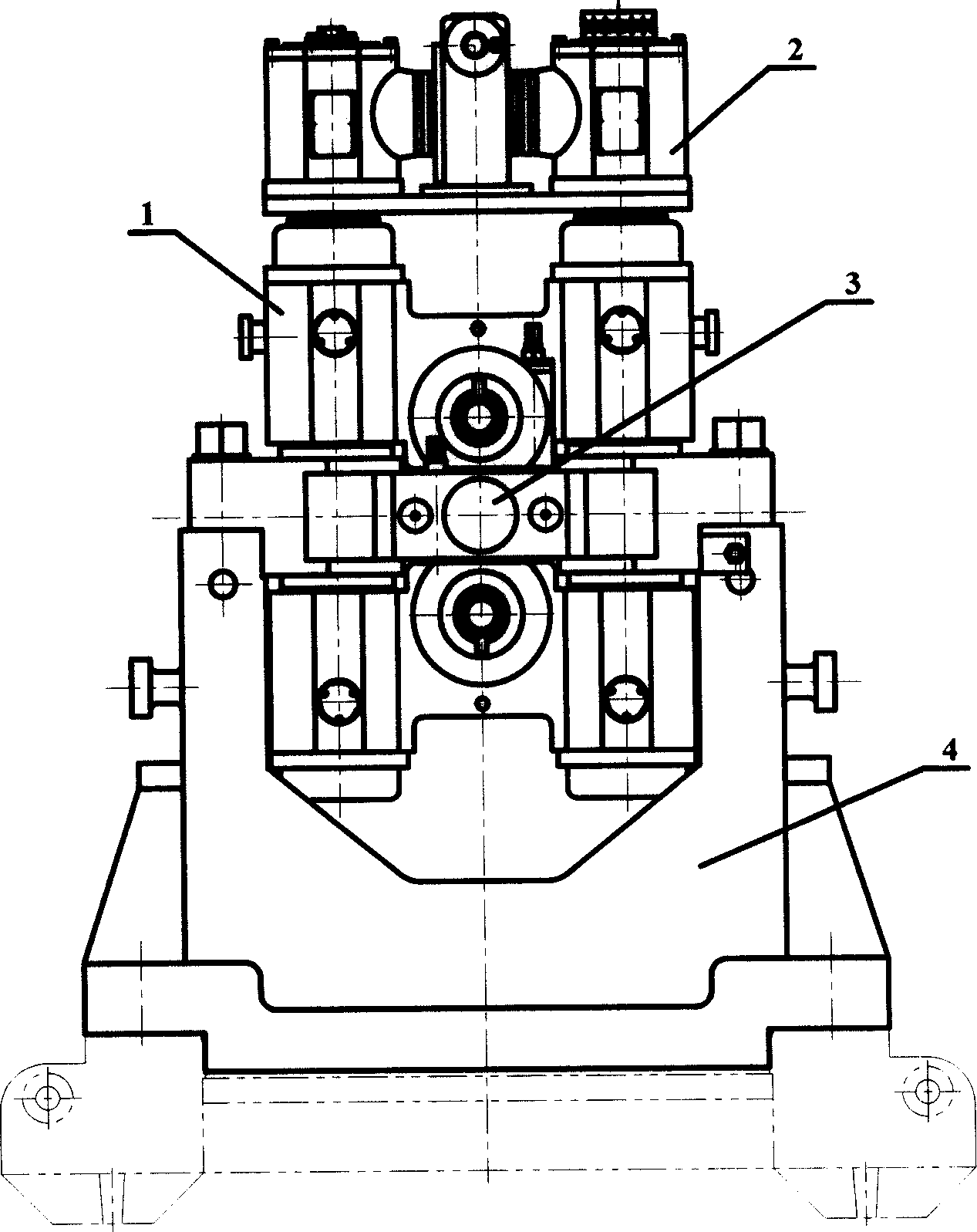

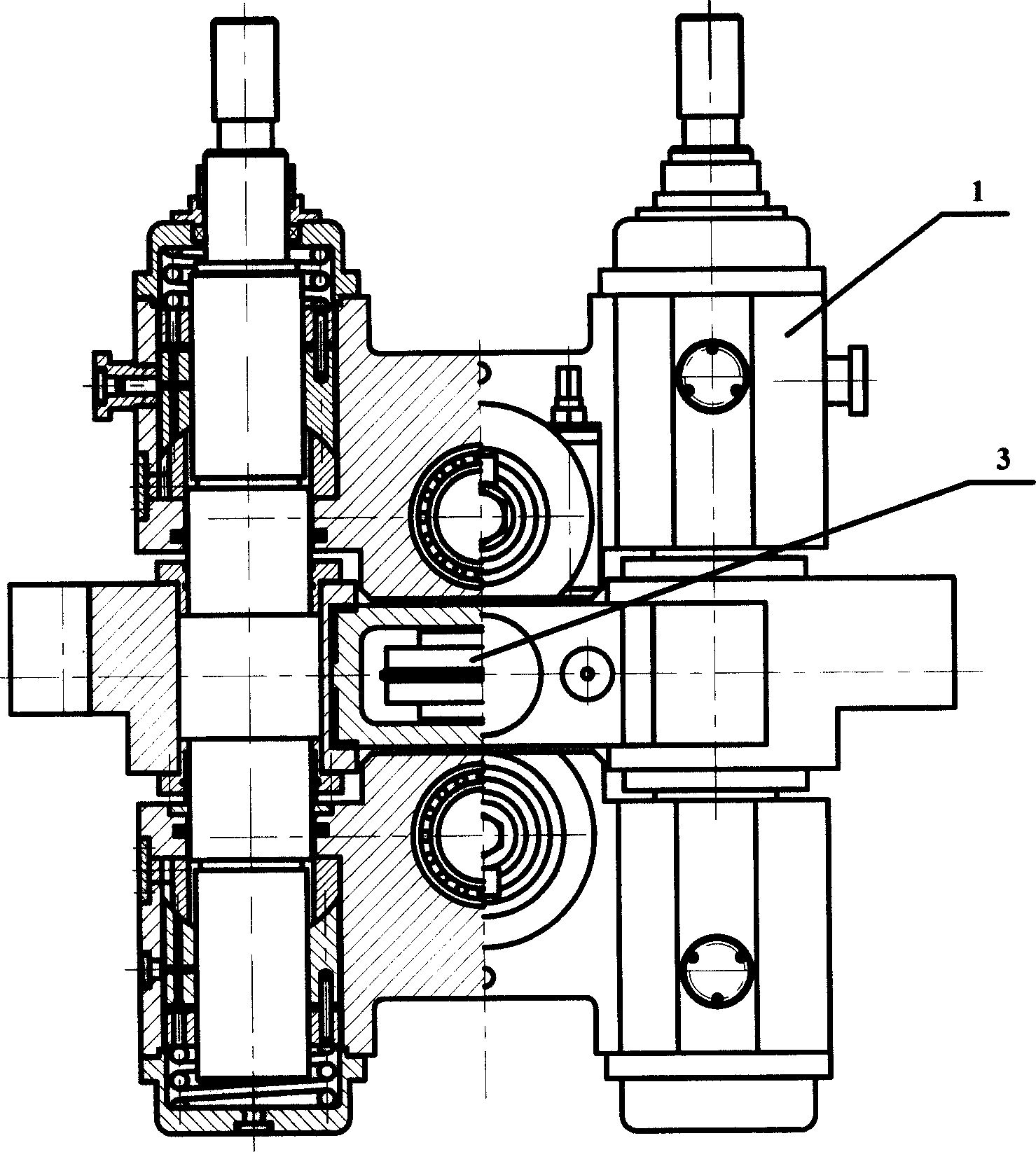

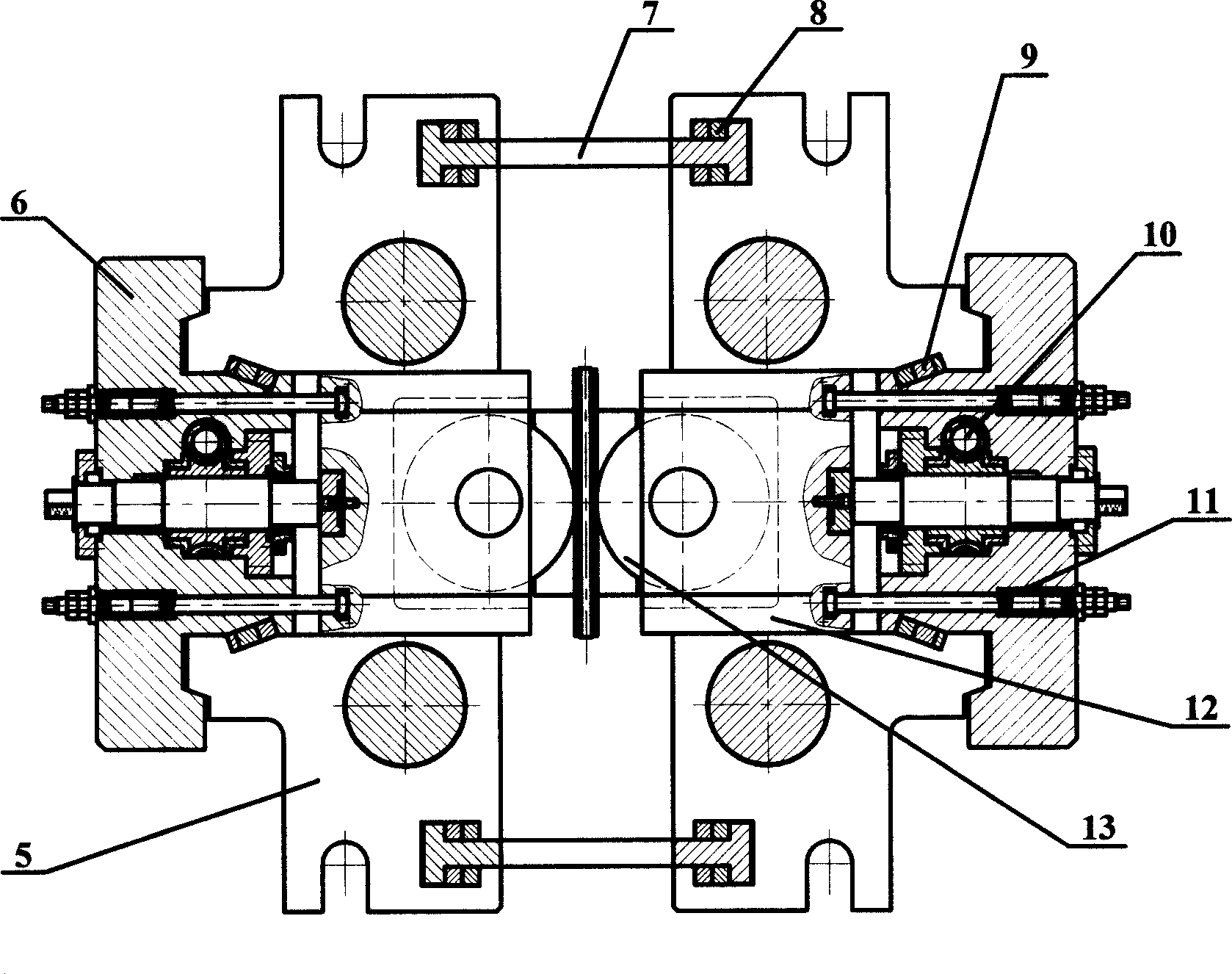

[0016] figure 1 It is an embodiment disclosed by the present invention. A universal space self-positioning high-rigidity rolling mill with a nominal diameter of the horizontal roll of 300mm. The vertical roll system 3 is installed in the semi-closed archway to form a closed stress line loop of the rolling force of the vertical roll, which is convenient for quick roll change under the condition of meeting the rigidity requirements, and is suitable for workers to operate easily. Both the horizontal roll ring 15 and the vertical roll ring 21 adopt a combined structure to highlight the local roll rings in contact with the anti-slip I-shaped flat steel, and use high-alloy chilled cast iron materials to make the roll rings to improve high temperature resistance, high pressure and wear resistance. Long working life and reduce the number of roll changes.

[0017] This universal space self-positioning high-rigidity rolling mill realizes the best forming and rolling of non-slip I-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com