Linkage interlocked padlock head

A blade lock and blade technology, which is applied in the field of locks, can solve the problems of different opening actions, enlarged axial and radial dimensions of the lock body, etc., and achieve the effect of good anti-prying and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

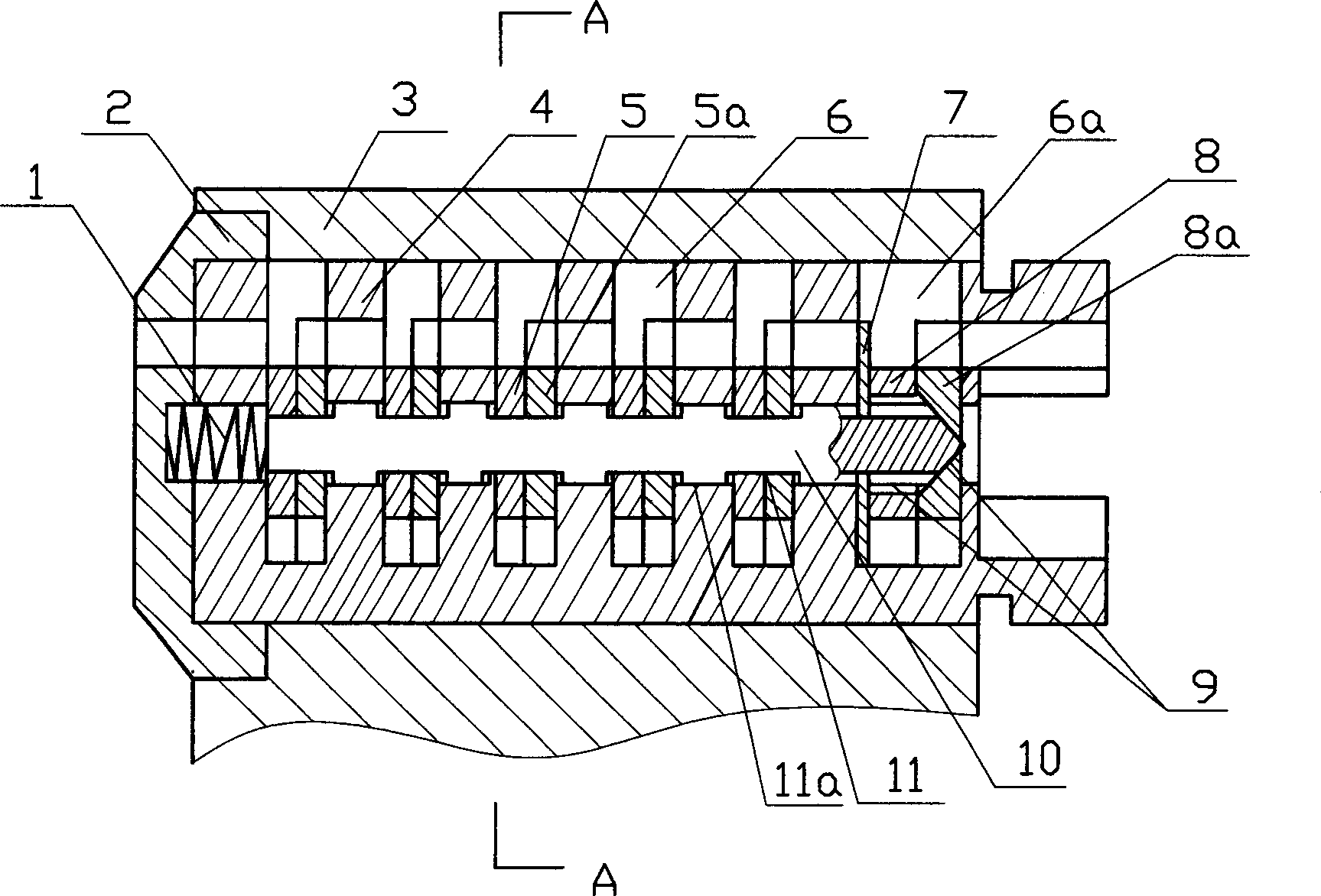

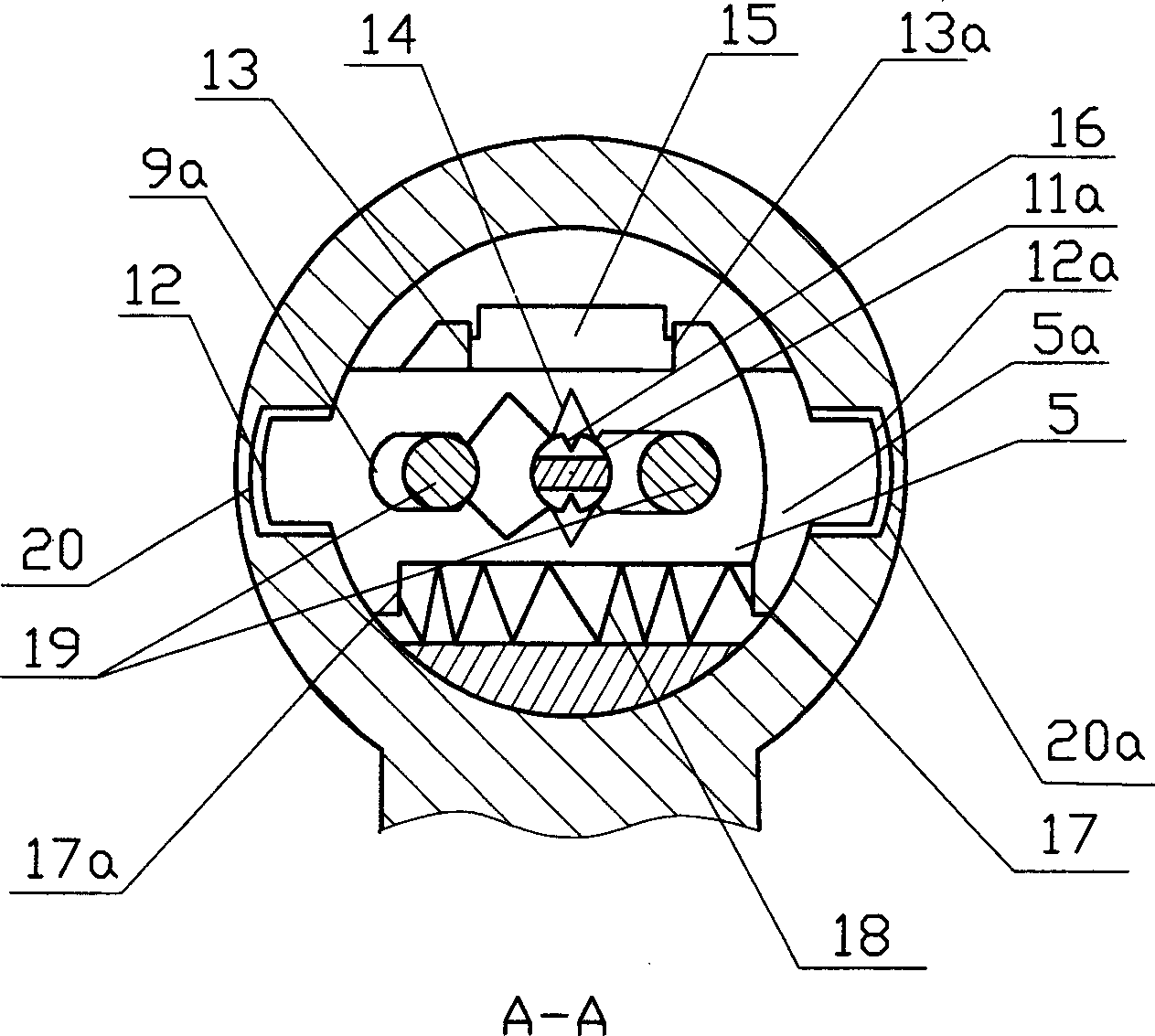

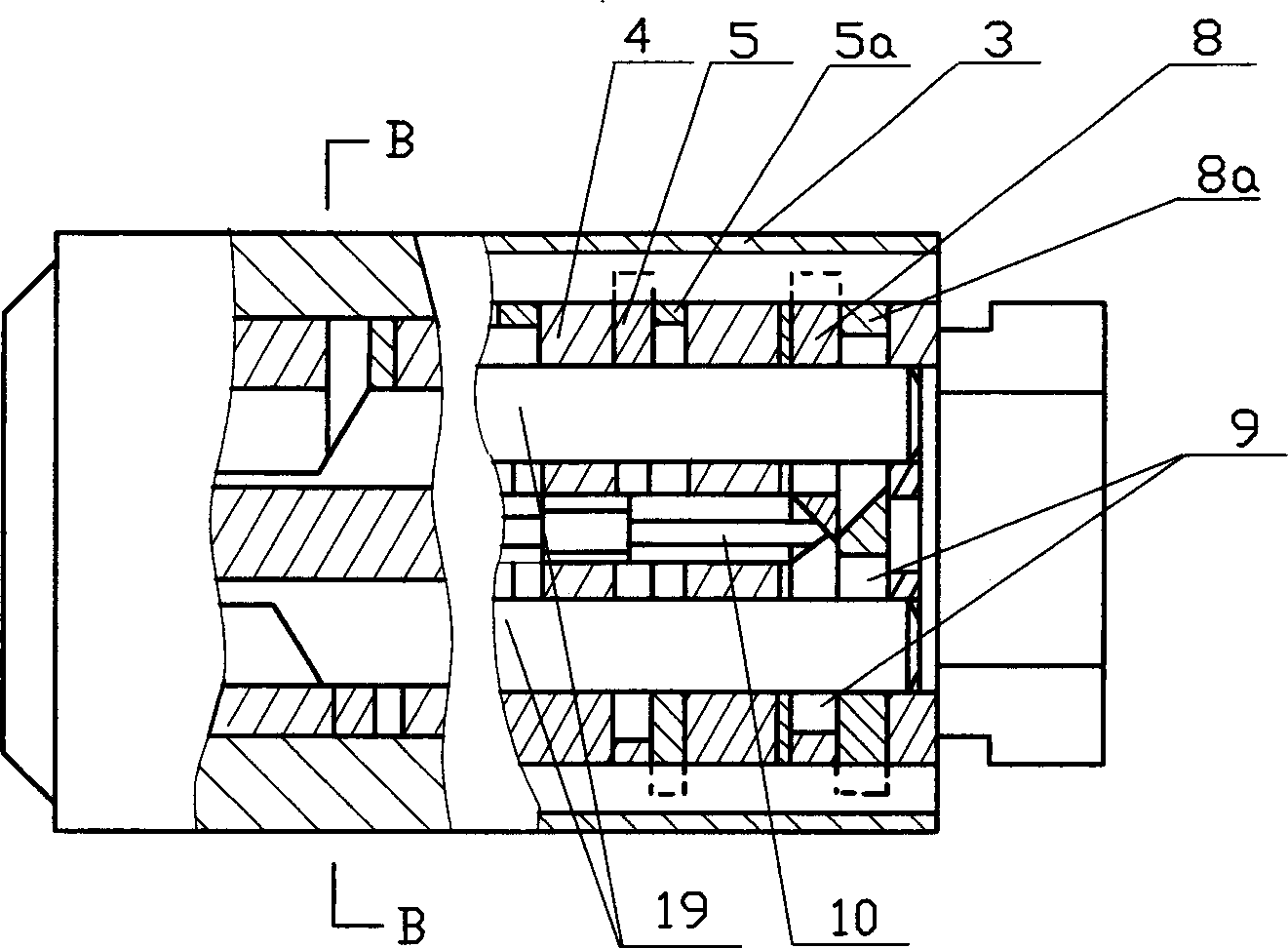

[0016] As shown in the figure, the lock body 3 has a round hole in the axial direction, and the entire rotating core 4 assembly is installed in the round hole. The left end of the lock body 3 is equipped with an anti-tamper cover 2, and the inner wall of the round hole is symmetrically provided with two locking grooves 20, 20a, the rotating core 4 is radially provided with five parallel blade transverse grooves 6 and one auxiliary blade transverse groove 6a, and five pairs of blades 5, 5a and a pair of auxiliary blades 8, 8a are respectively arranged in the blade transverse grooves 6 and the auxiliary blade transverse grooves In 6a, each pair of blades 5, 5a and auxiliary blades 8, 8a elastically cooperate with the return spring 18 through the ribs 17, 17a provided at the bottom, and under the action of the return spring 18, the blades 5, 5a, auxiliary blades 8, The blade lugs 12, 12a of 8a are inserted into the locking grooves 20, 20a. The rotating core 4 is axially provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com