Vehicular concrete conveying pump

A concrete delivery pump, vehicle-mounted technology, applied in the direction of pumps, liquid variable capacity machinery, machines/engines, etc., to achieve the effect of serious power waste, guaranteed stability and long operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

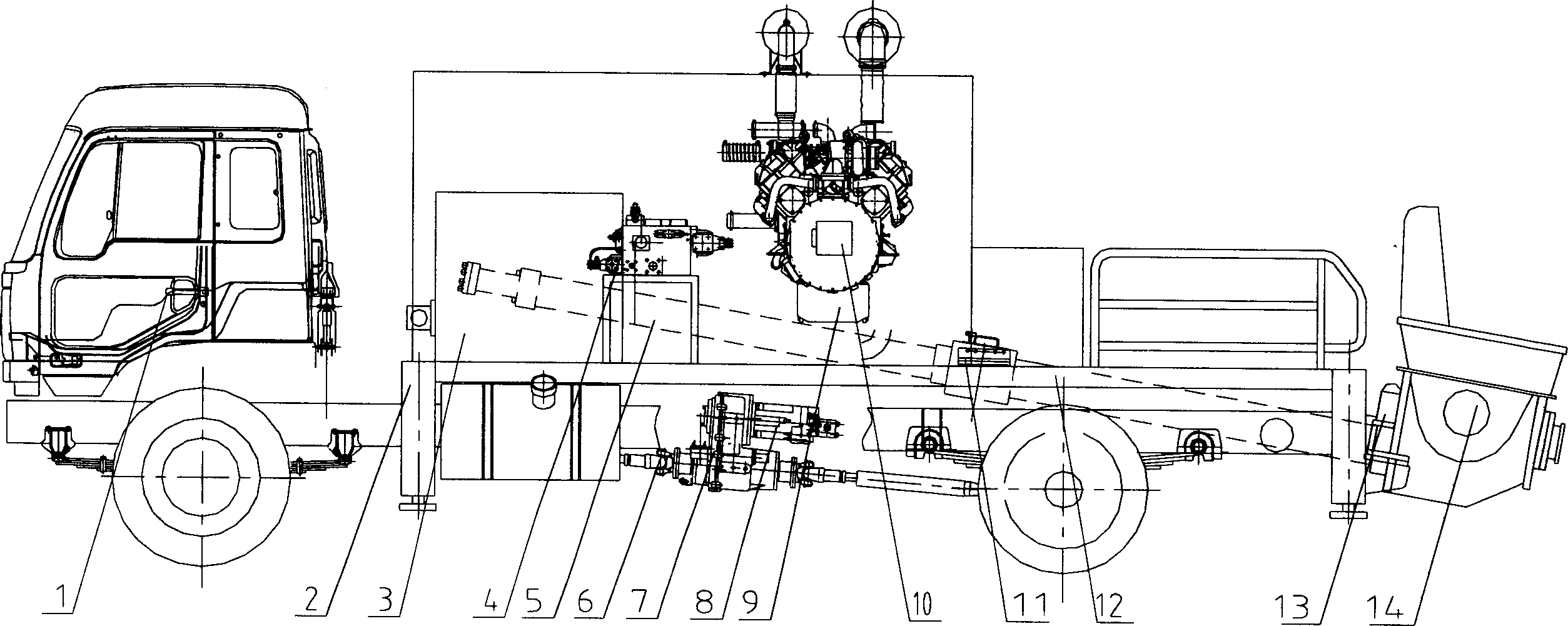

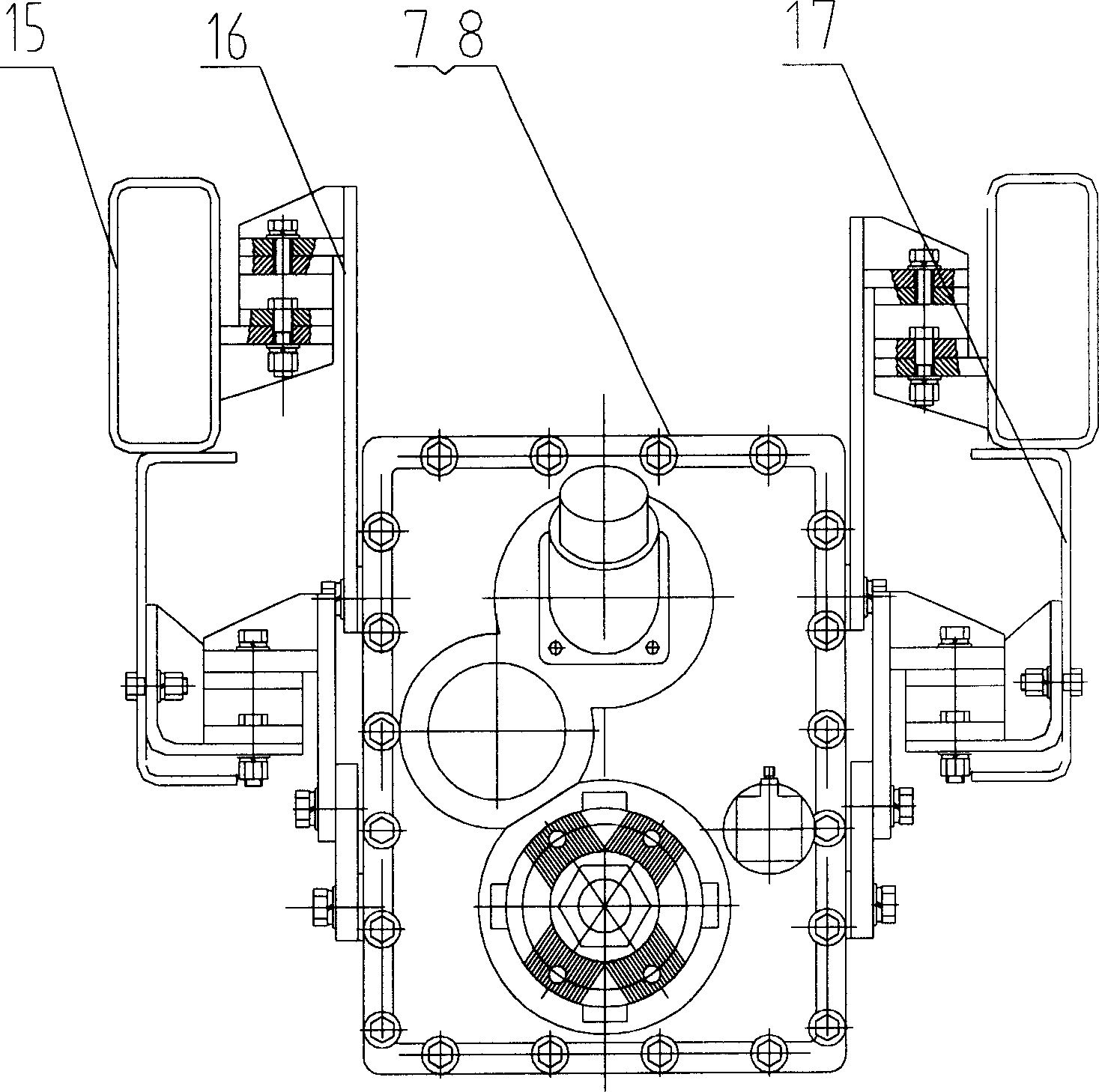

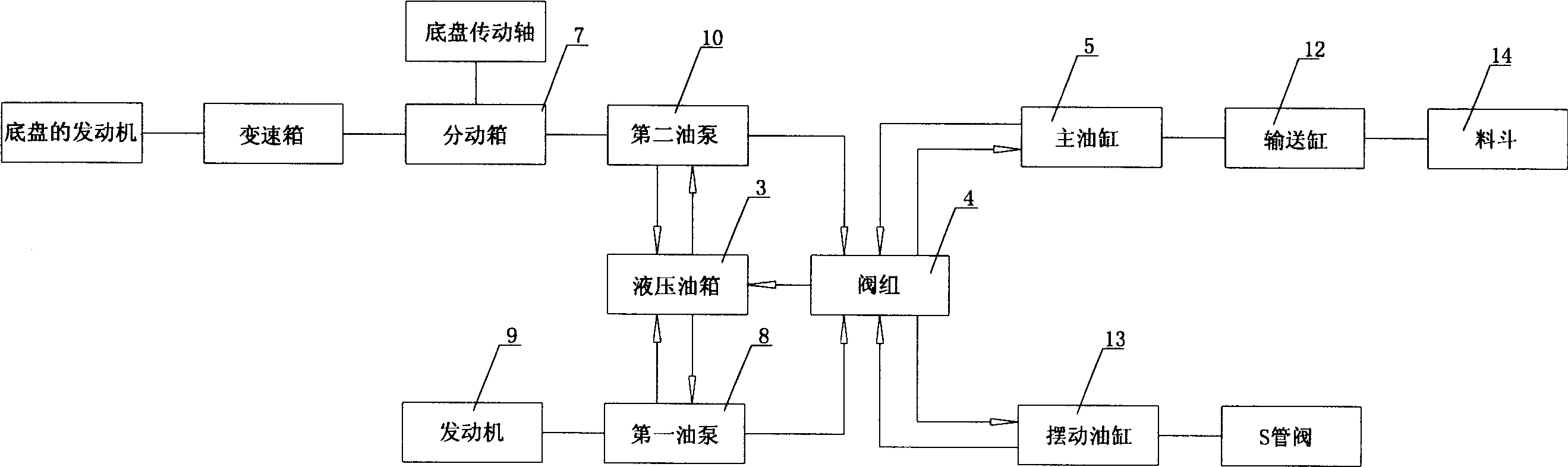

[0020] Such as figure 1 and figure 2 As shown, the vehicle-mounted concrete delivery pump of the present invention includes a chassis 1 and a pumping mechanism and a power system installed on the chassis 1. 11. Master oil cylinder 5, valve group 4 and hydraulic oil tank 3. The power system includes a bodywork power system and a chassis power system. The bodywork power system includes a first oil pump 10 and an engine 9. The first oil pump 10 is connected to the engine 9, and the other end passes through The pipeline and valve group 4 are connected with the main oil cylinder 5 and the swing oil cylinder 13; the chassis power system includes a transfer case 7 and a second oil pump 10, the transfer case 7 is connected with the engine of the chassis 1 through a transmission shaft 6, and the other end is connected with the second oil pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com