Stringed vertical curtain

A vertical direction and curtain blade technology, applied in the field of vertical curtains, can solve the problems of high maintenance cost, incompatibility, high production cost, etc., and achieve the effect of improving the utilization rate of wood, high utilization rate of materials, and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

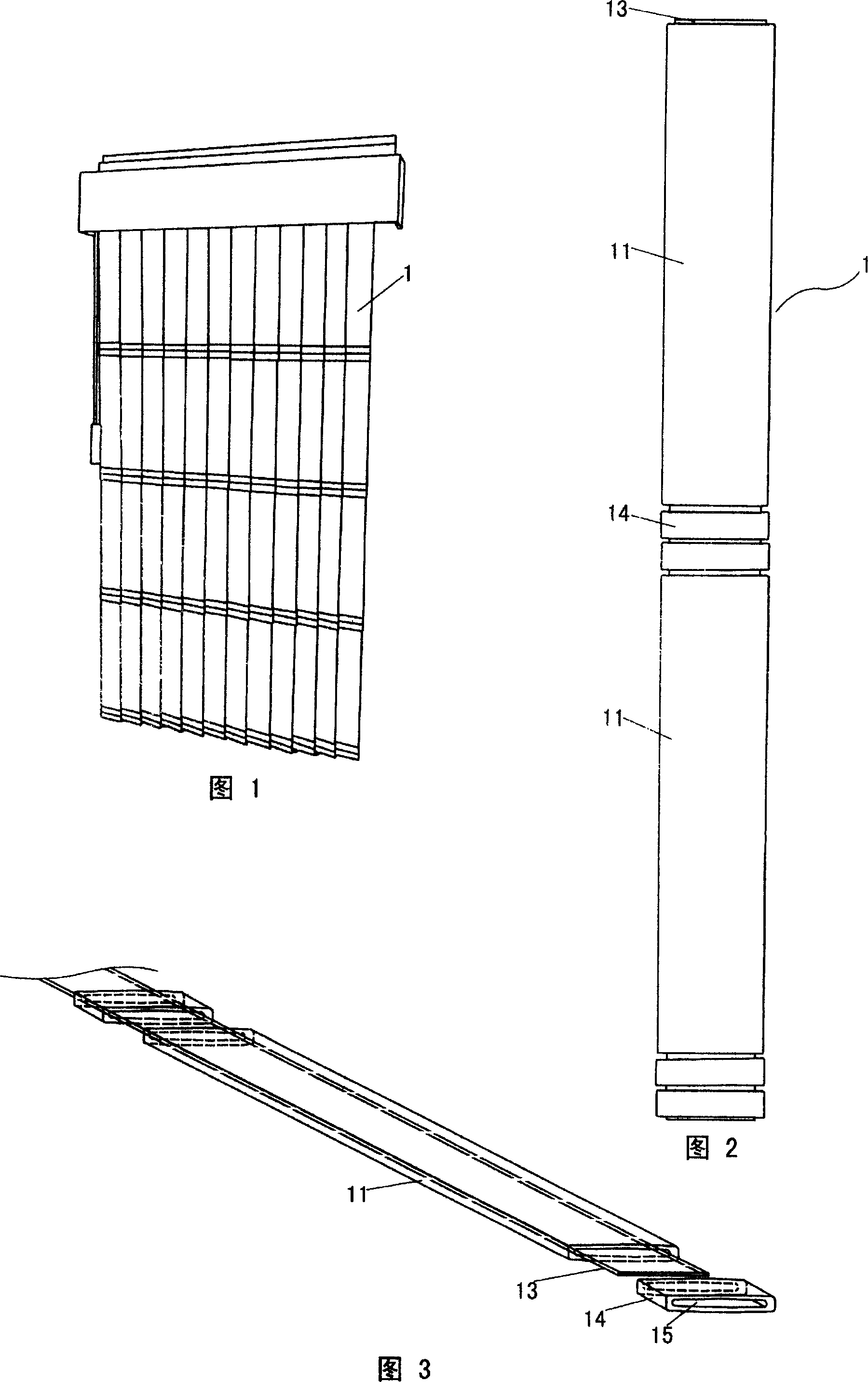

[0016] As shown in FIG. 2 , in this embodiment, the connectors of the multi-segment blades in the blind 1 are flexible connectors 13 , and the flexible connectors 13 are cloth tapes with a certain width. The number and length of the slats can be set according to the design requirements, and are not limited here. For example, in Fig. 1, according to the height of the window and the aesthetics, the slats of each curtain 1 include two long slats 11 and spaced apart long slats. 11 six decorative short leaf plates 14 . Each blade plate 11, 14 is longitudinally provided with a through hole 15 matching the width of the cloth tape 13 for the cloth tape 13 to pass through and install. During installation, as shown in Fig. 3, the cloth belt 13 is passed through the through holes 15 of each blade plate 11, 14 in turn, then hangs on the curtain bracket and is naturally vertical, which is very simple and convenient.

Embodiment 2

[0018] The connectors of the multi-section blades in the blind 1 are flexible connectors, and the flexible connectors are lanyards. A through hole is provided on the leaf plate for the penetrating installation of the lanyard. When the through hole is opened vertically, one or two long hanging ropes are passed through the through holes of each leaf plate in turn, and then hung on the curtain bracket; when the through hole is opened horizontally, several short hanging ropes are passed through the adjacent holes. The through holes of the blades are knotted to connect the two blades to form a continuous whole curtain. It is also possible to fix connecting parts on adjacent leaf plates, such as hanging rings, and then use several short lanyards to pass through the hanging rings of adjacent leaf plates and tie knots to connect the two leaf plates to form a continuous whole curtain leaf.

Embodiment 3

[0020] In the curtain leaf 1, metal connectors that can be hooked to each other are fixed on the adjacent blades, such as hanging rings and hooks, etc., directly hook the metal connectors on the adjacent blades to each other, and connect the two blades. rise up, and finally form a continuous whole piece of curtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com