Muffler for hermetic rotary compressor

A rotary compressor and muffler technology, applied in the field of compressor devices, can solve the problems of increasing compressor noise, high-pressure gas leakage, reducing the efficiency of the muffler 11, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0038] The same symbols are used for the same parts in the figures.

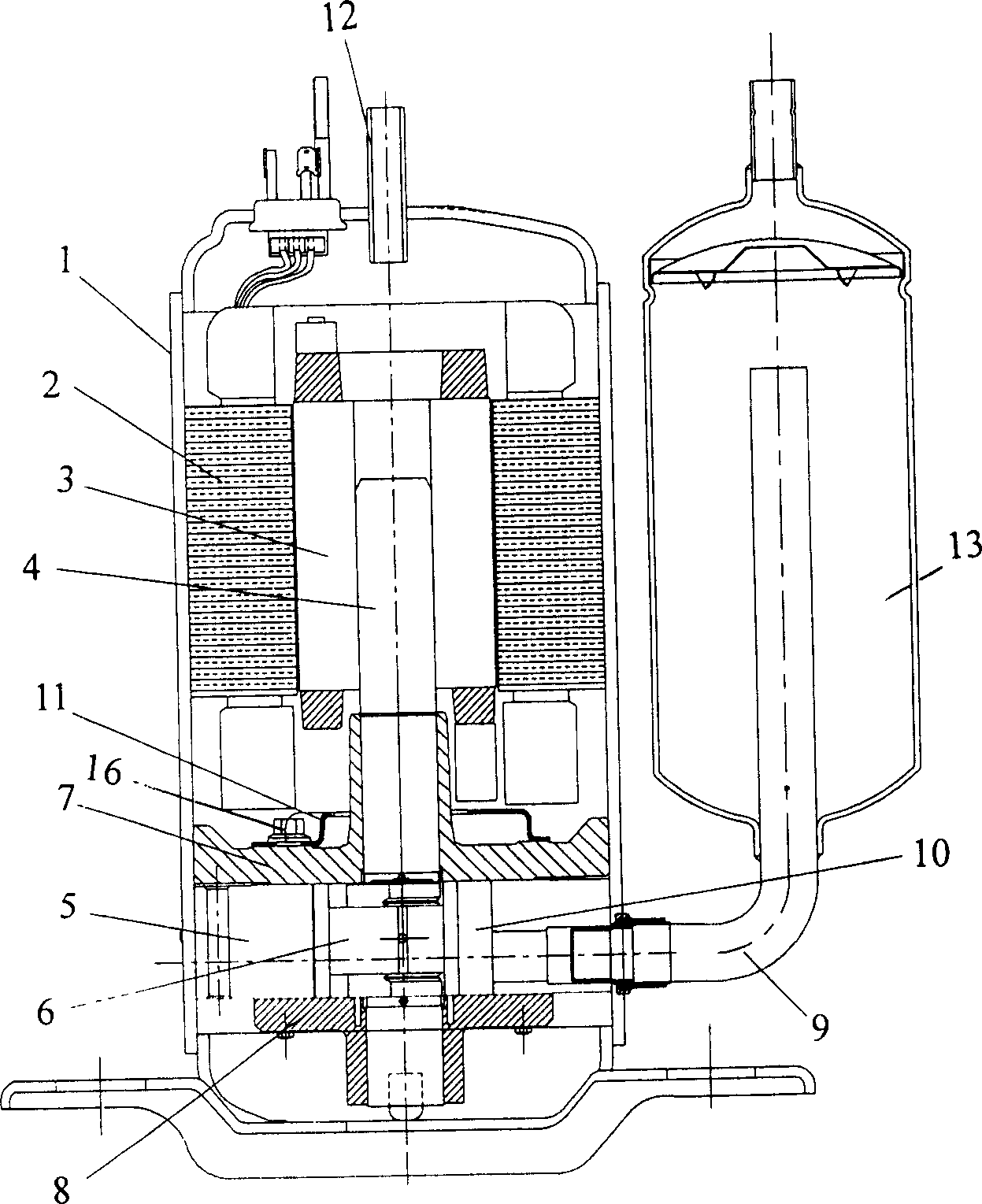

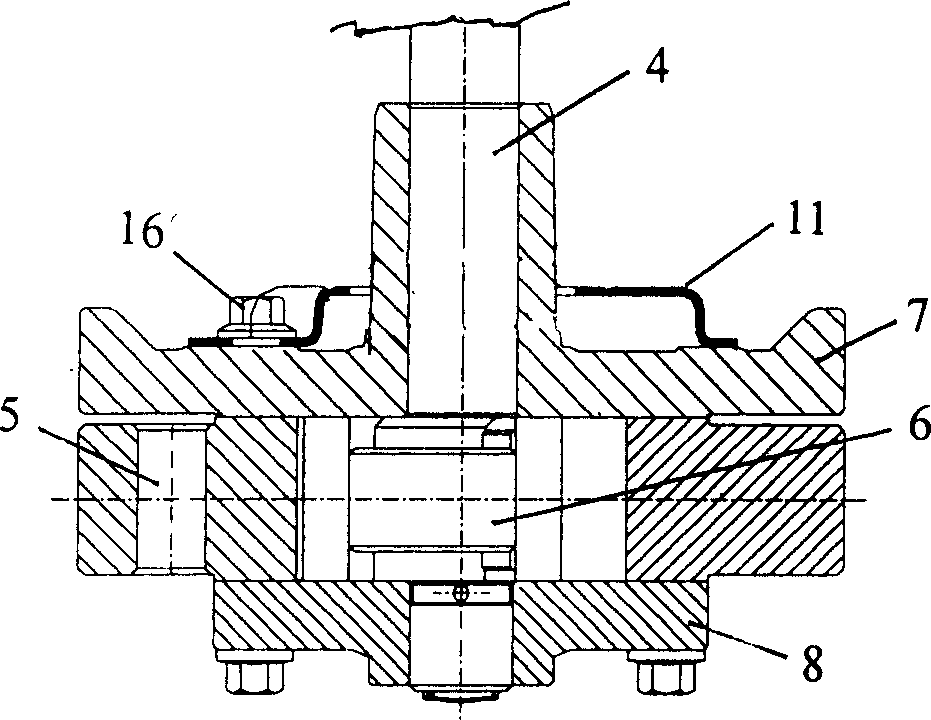

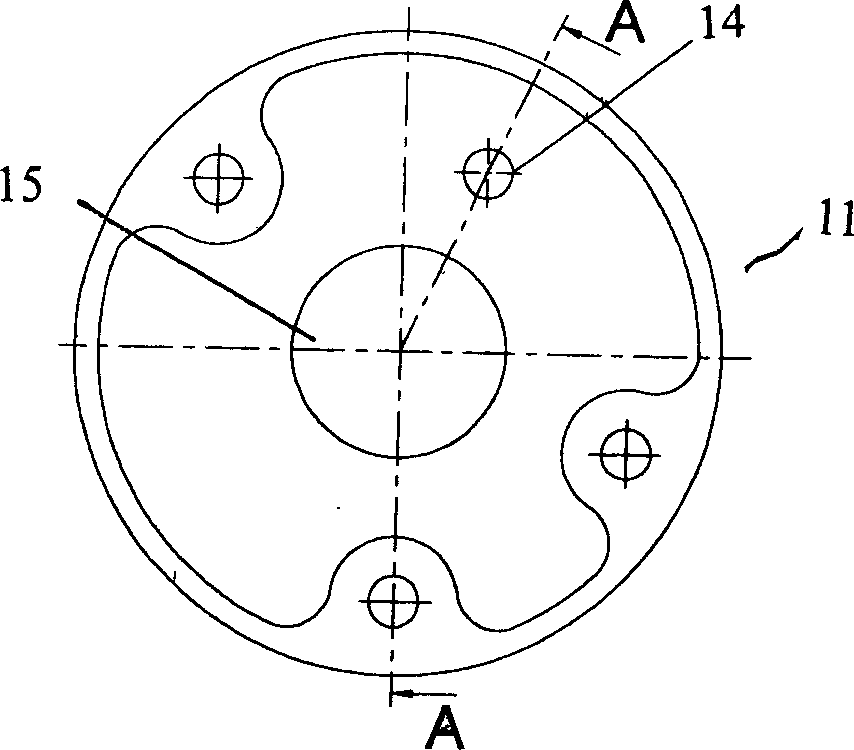

[0039] A muffler for an airtight rotary compressor, comprising a motor stator 2 and a rotor 3 arranged in the upper part of an airtight casing 1, a compressor is arranged at the lower end of an eccentric shaft 4 in the center of the rotor 3, and a compressor cylinder body at the lower part of the airtight casing 1 5, there is a rolling piston 13 on the outer peripheral surface of the eccentric part 6 of the eccentric shaft 4, and the upper and lower end surfaces of the cylinder block 5 are fixed with an upper bearing 7 and a lower bearing 8 that are sealed and support the rotation of the eccentric shaft 4, and the upper bearing 7 is installed with The muffler 11 that penetrates the neck shaft of the upper bearing 7 through the shaft hole 15 ; the outer ring wall 17 that is sealed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com