Rotor of motor and motor

A motor and rotor technology, applied in the field of motors, can solve the problems of stator induced voltage reduction and insufficient rotational driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

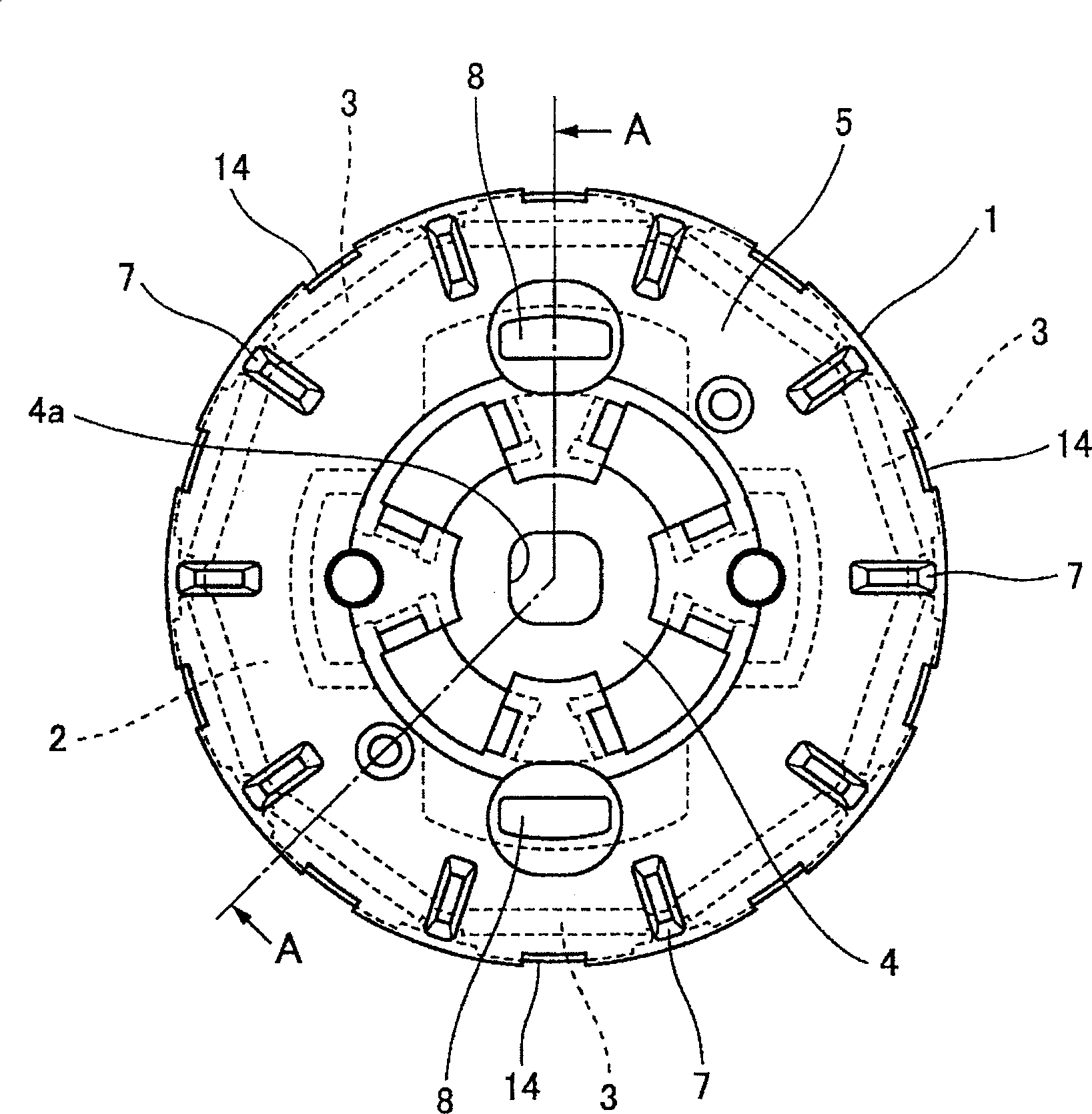

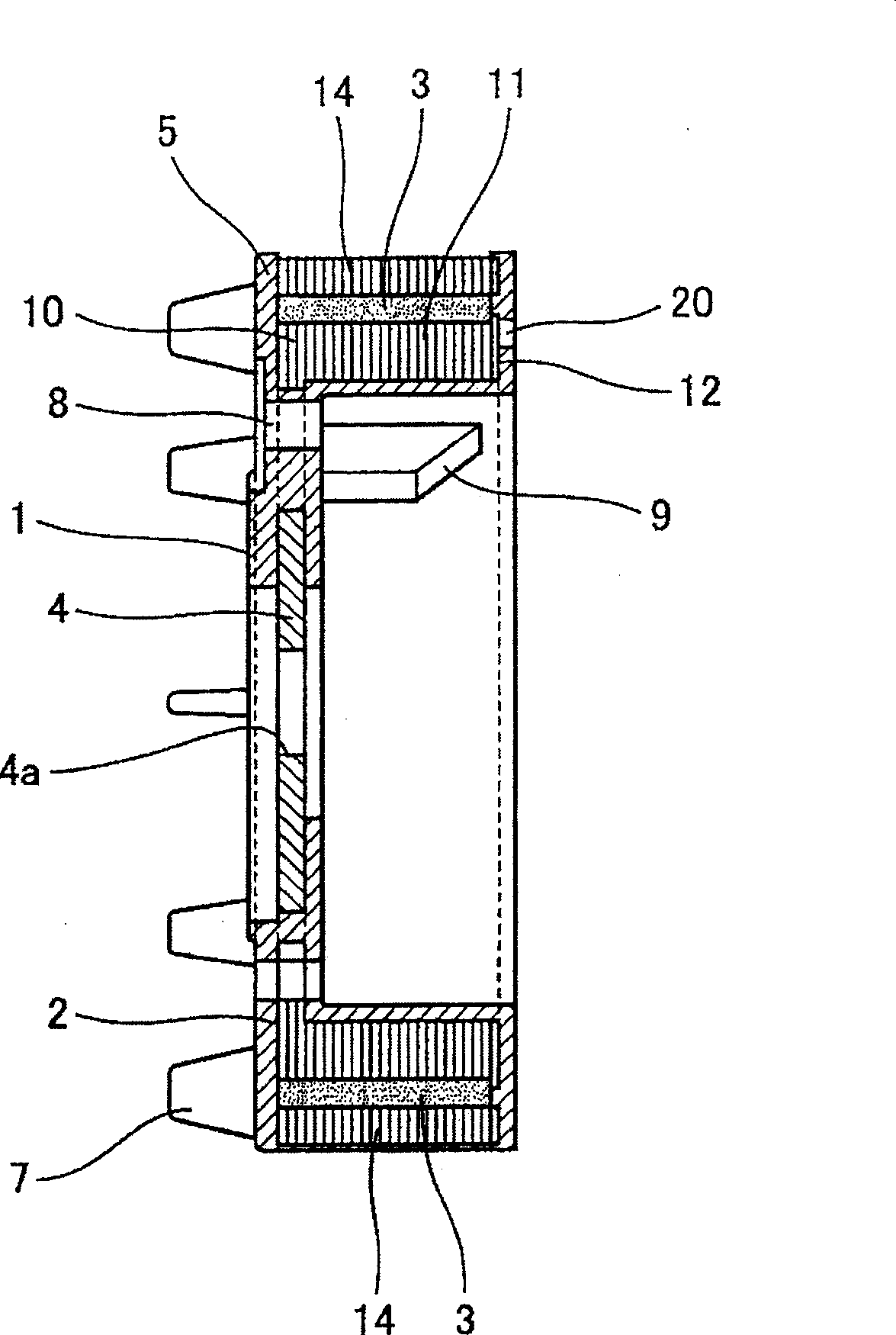

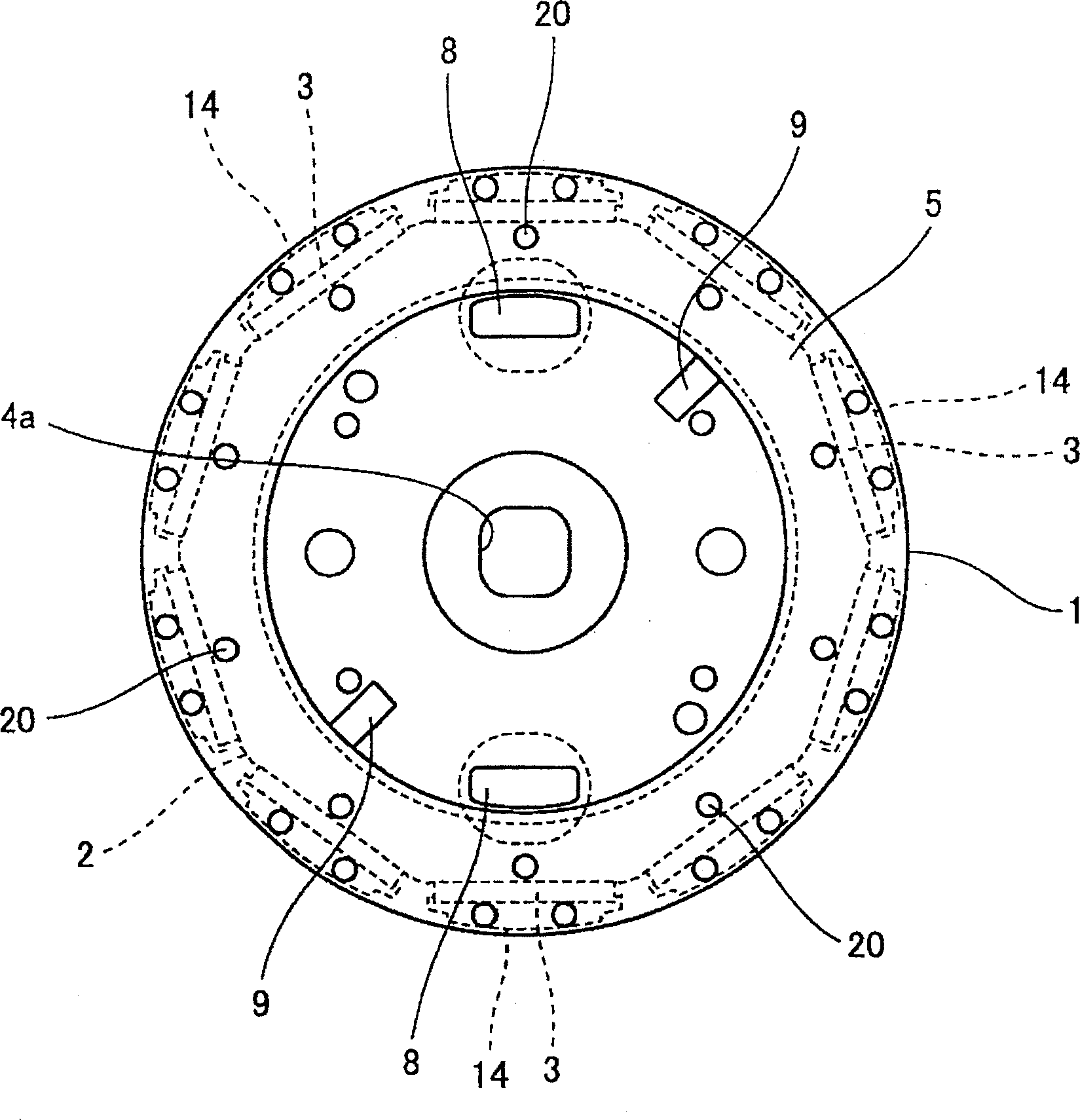

[0029] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0030] First, with Figure 17 The structure of the motor according to the present invention will be briefly described. Such a motor 30 has a rotor 1 connected to a rotating shaft 34 and a stator 32 fixedly provided to face the outer circumference of the rotor 1 . This type of motor is an inner type motor in which the stator 32 is arranged on the outside and the rotor 1 is arranged on the inside. Inside the rotor 1 of this motor, a rotor core 2 with a plurality of permanent magnets 3 loaded along its rotation direction is installed. On the other hand, an electromagnetic coil 32a is provided on the stator 32. The rotor 1 rotates relative to the stator 32 through the electromagnetic action between them, driving the rotating shaft 34 integrated with it to rotate.

[0031] The present invention relates to the structure of the rotor 1 used in such a motor 30 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com