Device for handling components and method of controlling

A control method and a technology for manipulating components, which are applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve problems such as blowing away and component movement, and achieve the effects of improving assembly efficiency, simple structure, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

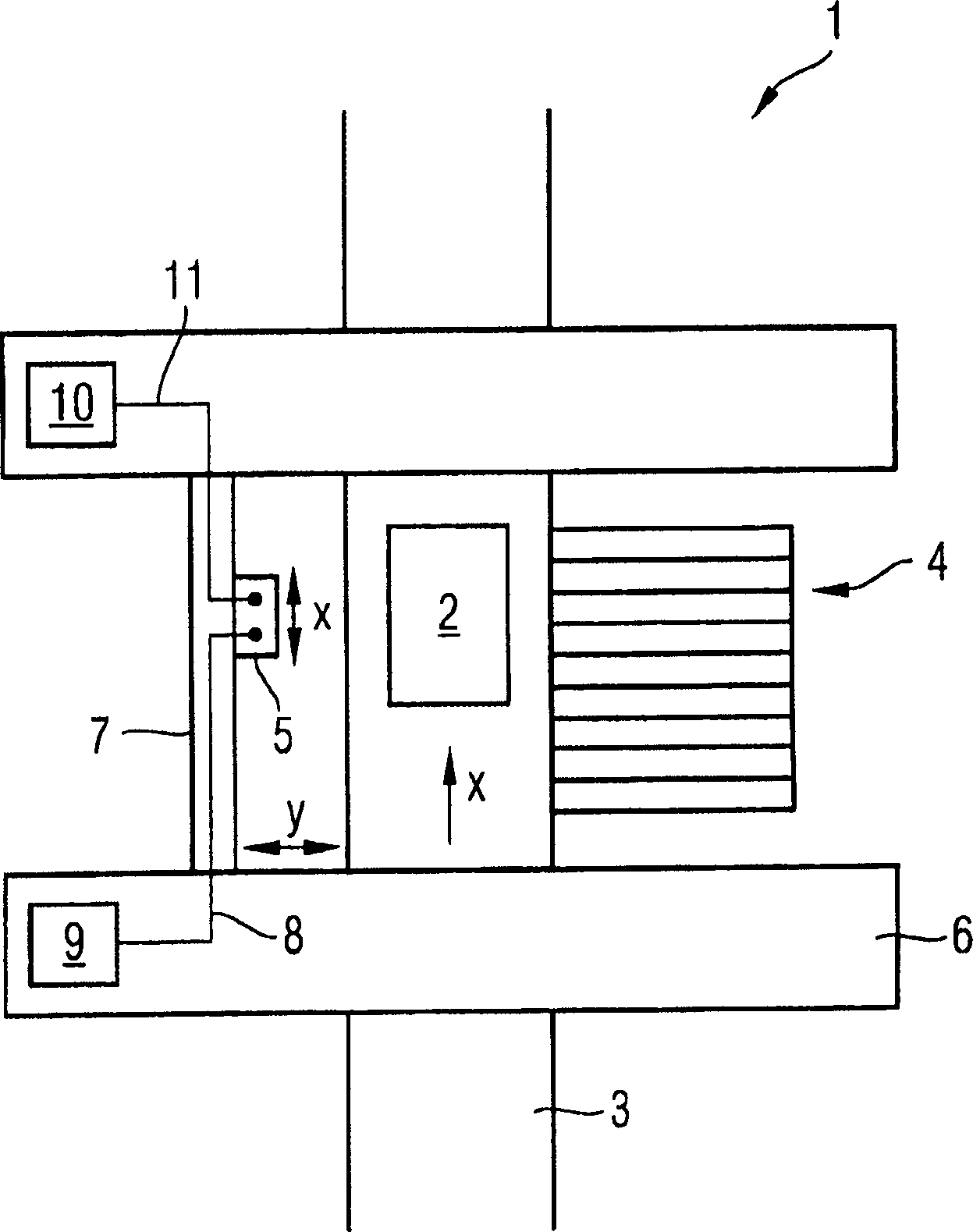

[0021] exist figure 1 An embodiment of an inventive device for manipulating components or an automatic assembly machine 1 for assembling electrical components to a circuit board 2 is schematically shown in FIG. The circuit boards 2 to be assembled are conveyed along the conveying line 3 in the conveying direction (arrow x) to the assembly station, assembled there, and conveyed further. On the part of the conveyor line 3, there is a feed device 4 for supplying electrical components in the feed area. The assembly head 5 is arranged to be travelable between the feeding device 4 and the assembly position by means of a positioning system. The positioning system here comprises two beams 6 of the gantry crane type, which span the conveying line 3 in the form of a bridge, and a longitudinal beam 7 which is movably supported at its ends on the beams 6 and which, for example by means of Due to the linear motor it is possible to travel transversely to the conveying direction (arrow y)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com