Method for mixing solid powder and liquid and axial flow type mixer therefor

A solid powder and mixer technology, applied in chemical instruments and methods, mixing operation control, mixing operation control devices, etc., can solve the problems of inability to control dry ash, low control precision, single variable control, etc., and achieve simple structure and control High-precision, fast-blending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

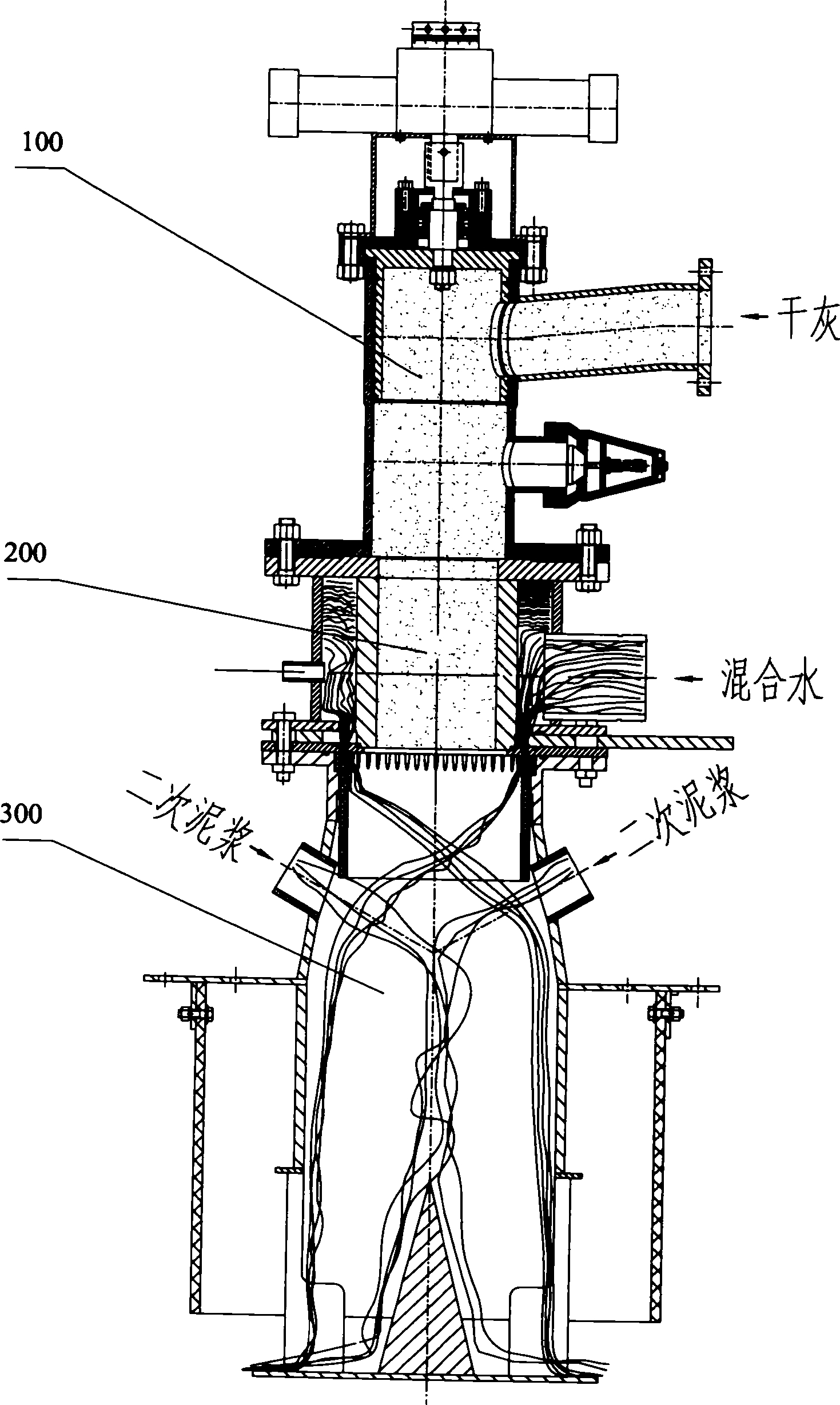

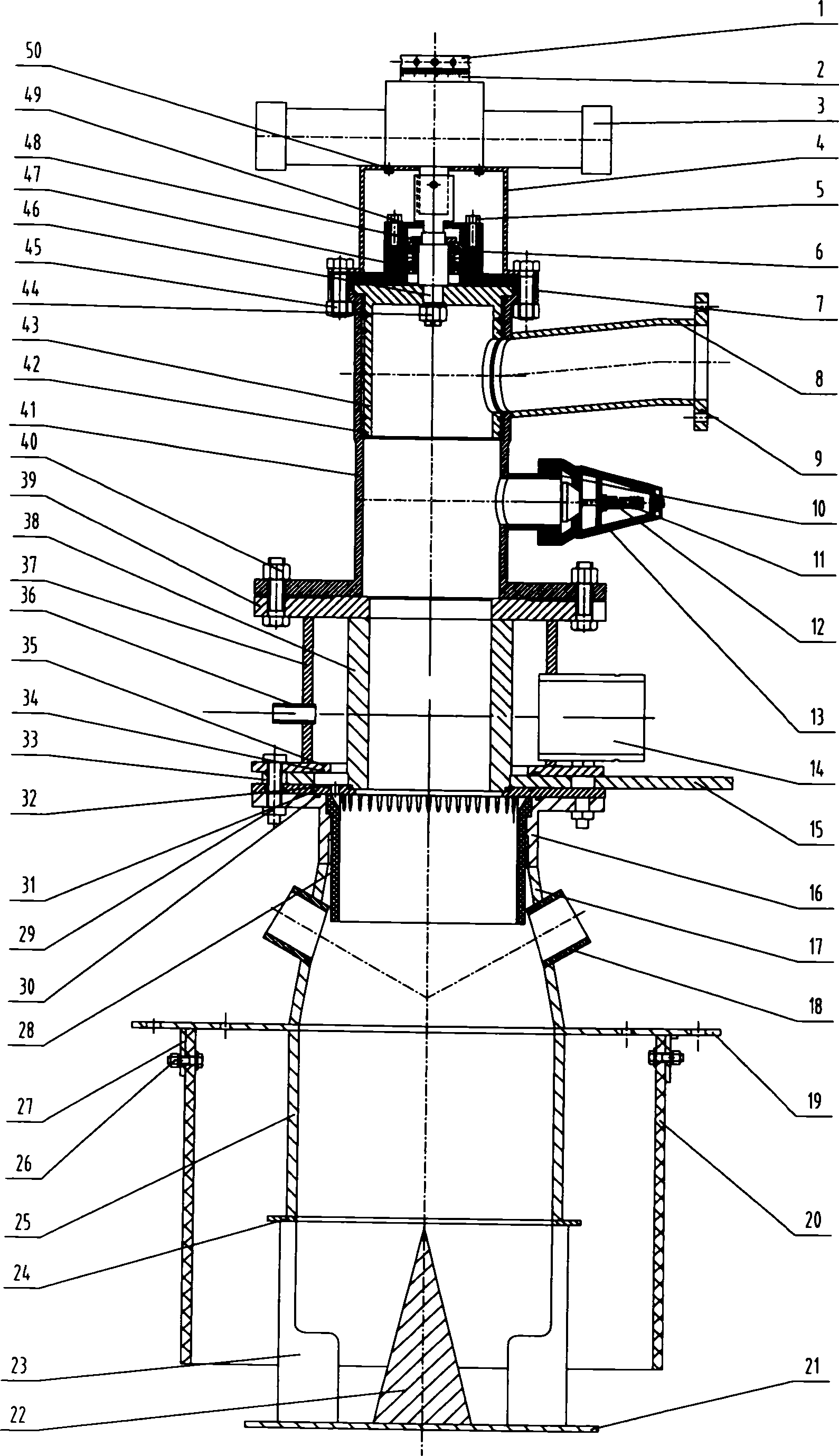

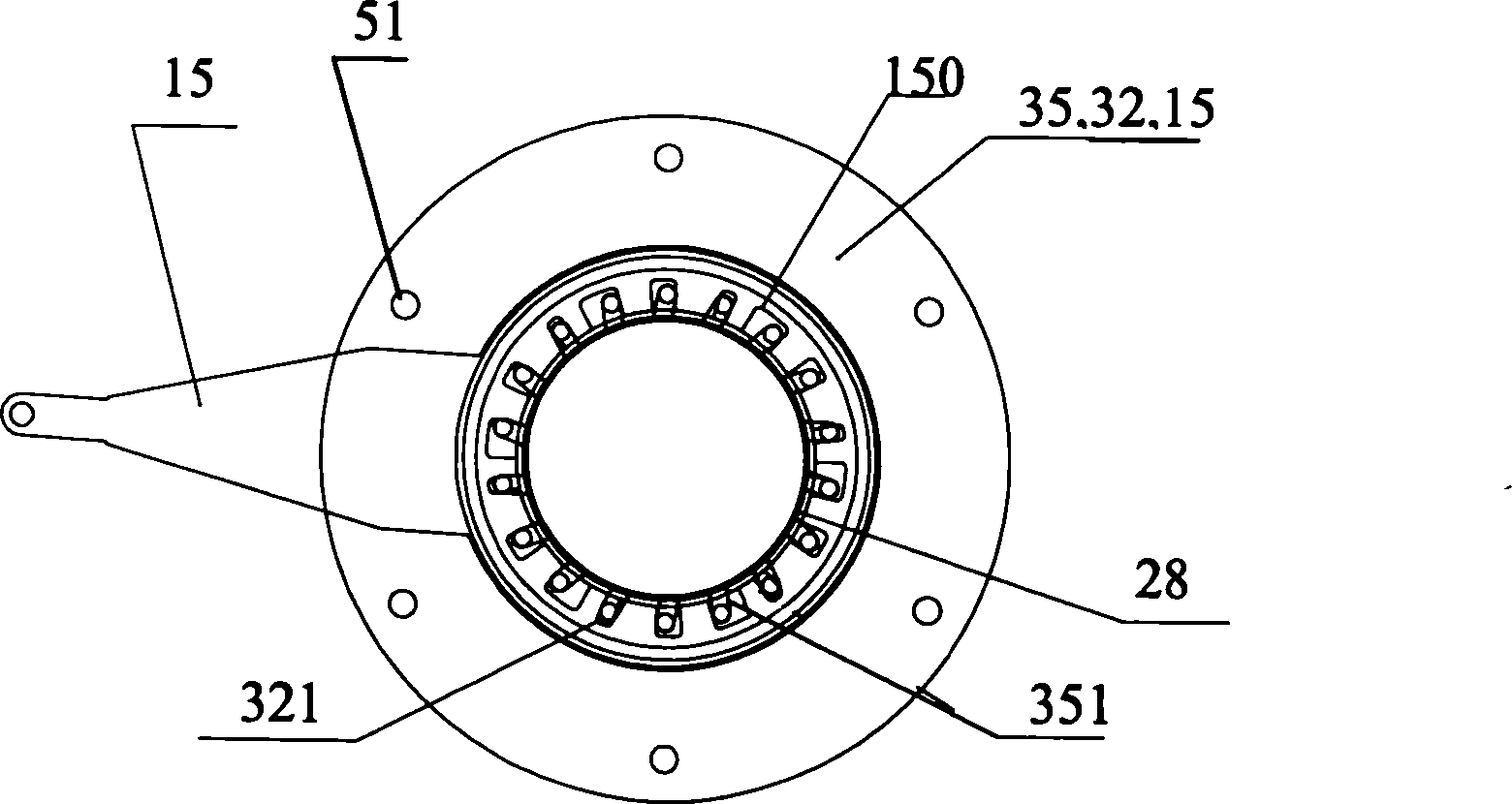

[0039] This embodiment takes the mixing of dry ash and clear water as an example. During the working process, the axial flow mixer adopts a double-variable control method, which controls both the flow of dry ash and the flow of clean water. Such as figure 1As shown, the axial flow mixer in this embodiment consists of three parts: a dry ash proportional valve 100 , a clean water proportional valve 200 and a mixing head 300 . The dry ash proportional valve 100 is at the upper end of the clean water proportional valve 200, and the mixing head 300 is at the lower end of the clean water proportional valve 200. The inner cavities of the three parts form a chamber connected up and down, and sealing measures are taken between each other. With thread and flange connection. Dry ash enters the chamber from the top, mixed water enters the chamber from the middle, and secondary cement slurry enters the chamber from the bottom. The amount of dry ash entering is controlled by a dry ash pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com