Non-impact transfer printing method and device therefor

A technology for transfer paper and transfer objects, applied in the field of transfer devices, can solve the problems of insurmountable resolution, damage to the surface of the object to be transferred, and inability to copy colored patterns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

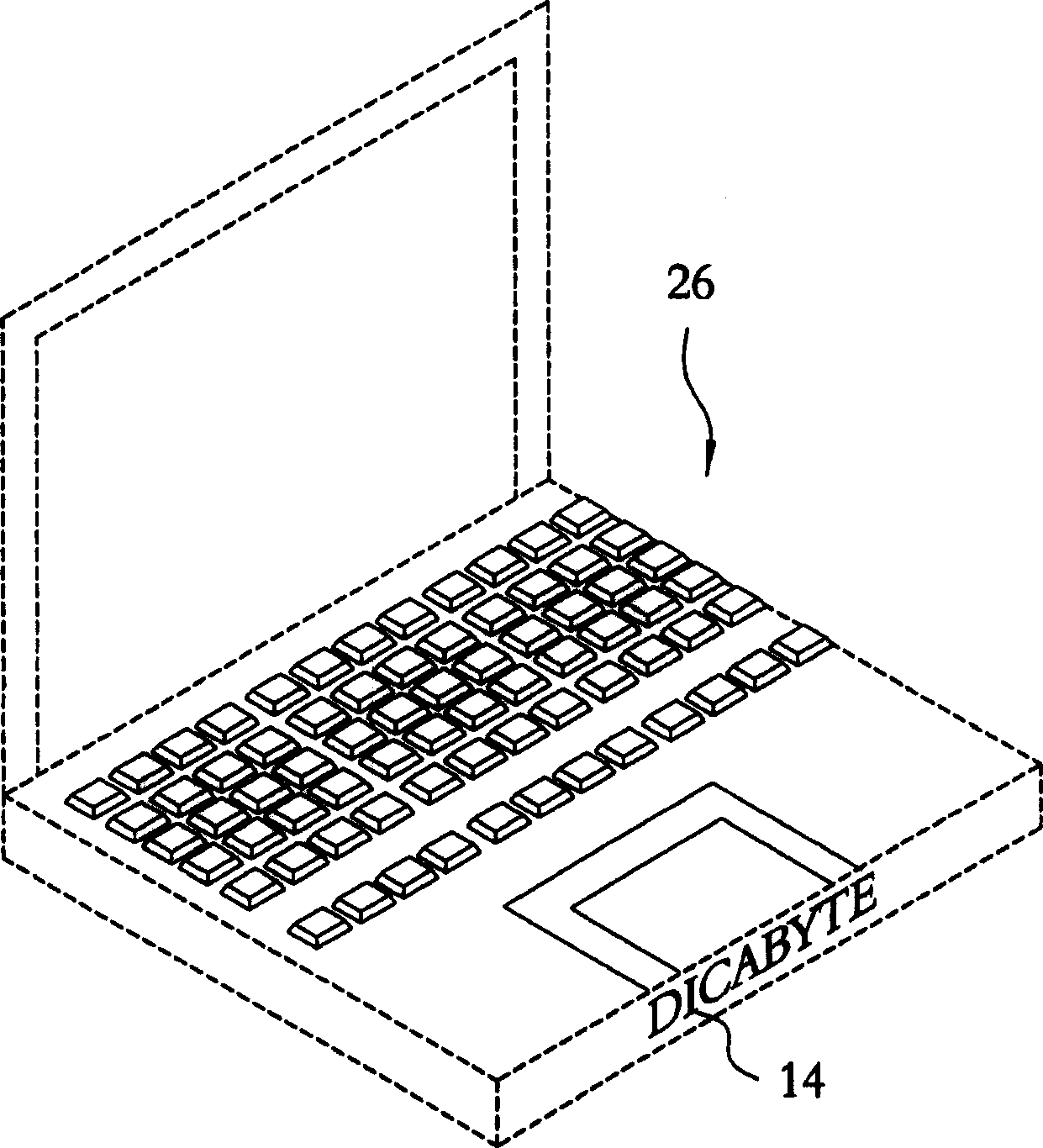

[0027] The method of the present invention is most suitable for use on image transfer materials made of polyvinyl chloride (PVC) plastic sheets. The PVC image transfer sheet allows the sheet to smoothly transfer a full-color image onto the curved surfaces and angles of an object, such as the case of a laptop computer. Typical laptop casings are made of ABS, polycarbonate (PC) and a blend or composite of ABS and PC, which are compatible with the PVC image transfer sheet used in the process of the present invention.

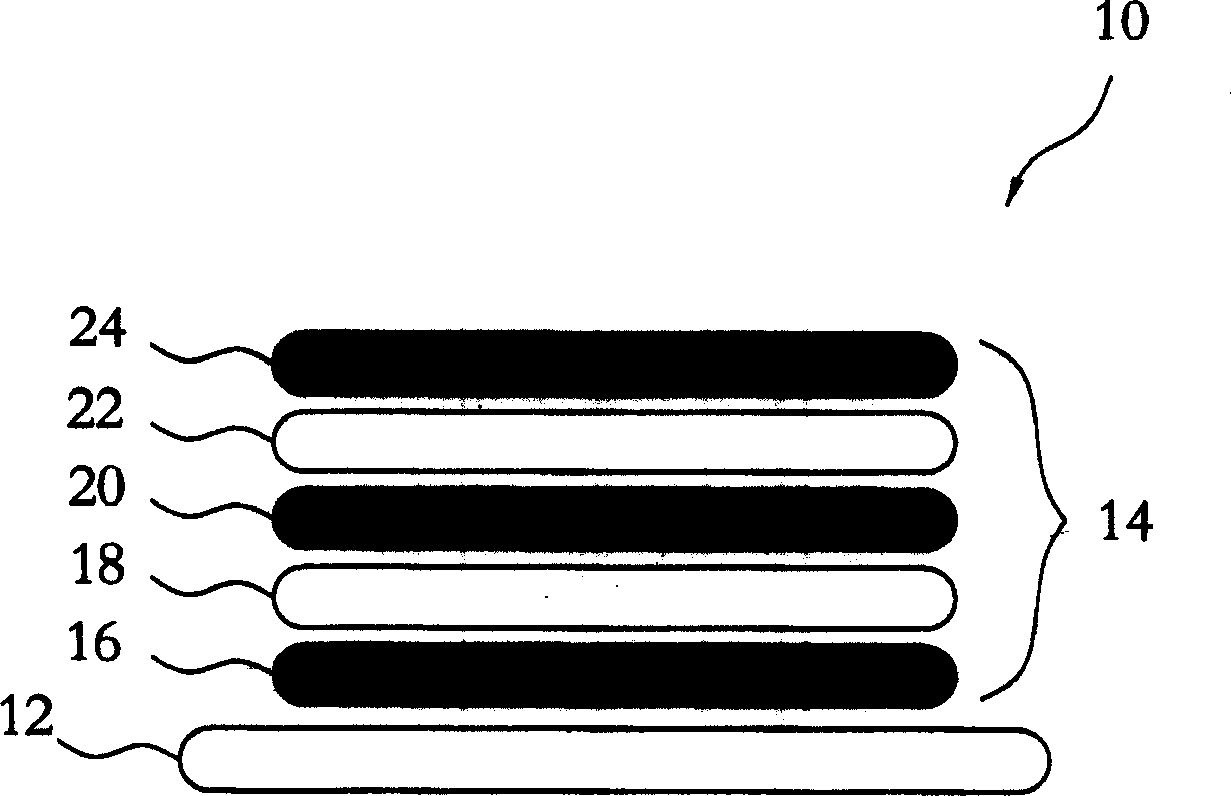

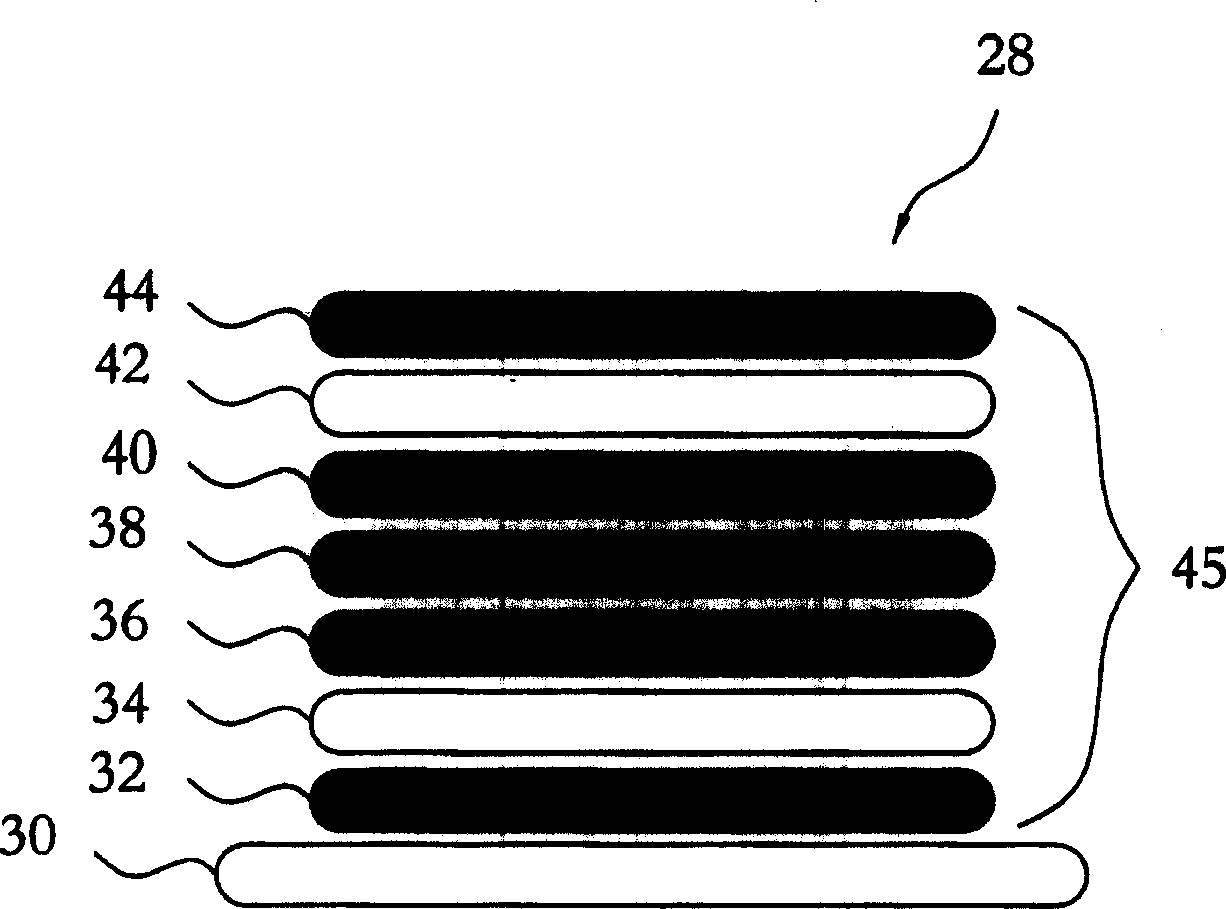

[0028] see now figure 1 It is the sectional view of the plateless transfer printing method and its device of the present invention and the plateless transfer paper image 3 The three-dimensional view of the appearance of the notebook computer printed for the method and device of the plateless transfer printing of the present invention, as shown in the figure, uses a plateless transfer paper 10 for transfer printing. There is a PVC plastic paper 12 on the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com