Machine room-free elevator

A technology without mechanical rooms and elevators. It is used in elevators, lifts, transportation, and packaging in buildings. It can solve problems such as reducing the size of elevator pits, and achieve the advantages of reducing size, convenient setting, and shortening assembly and maintenance time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the elevator without a machine room according to the present invention will be described below with reference to the drawings.

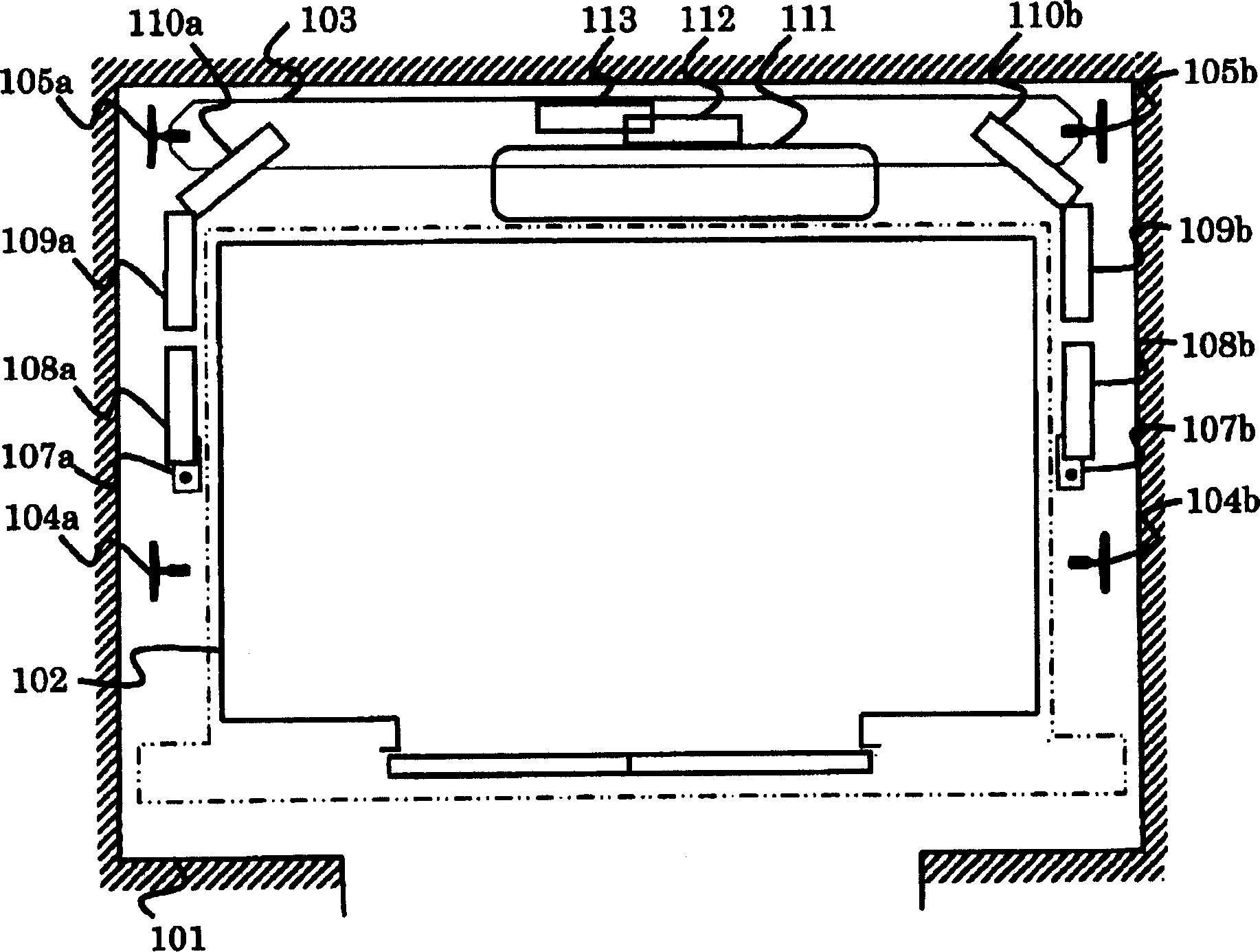

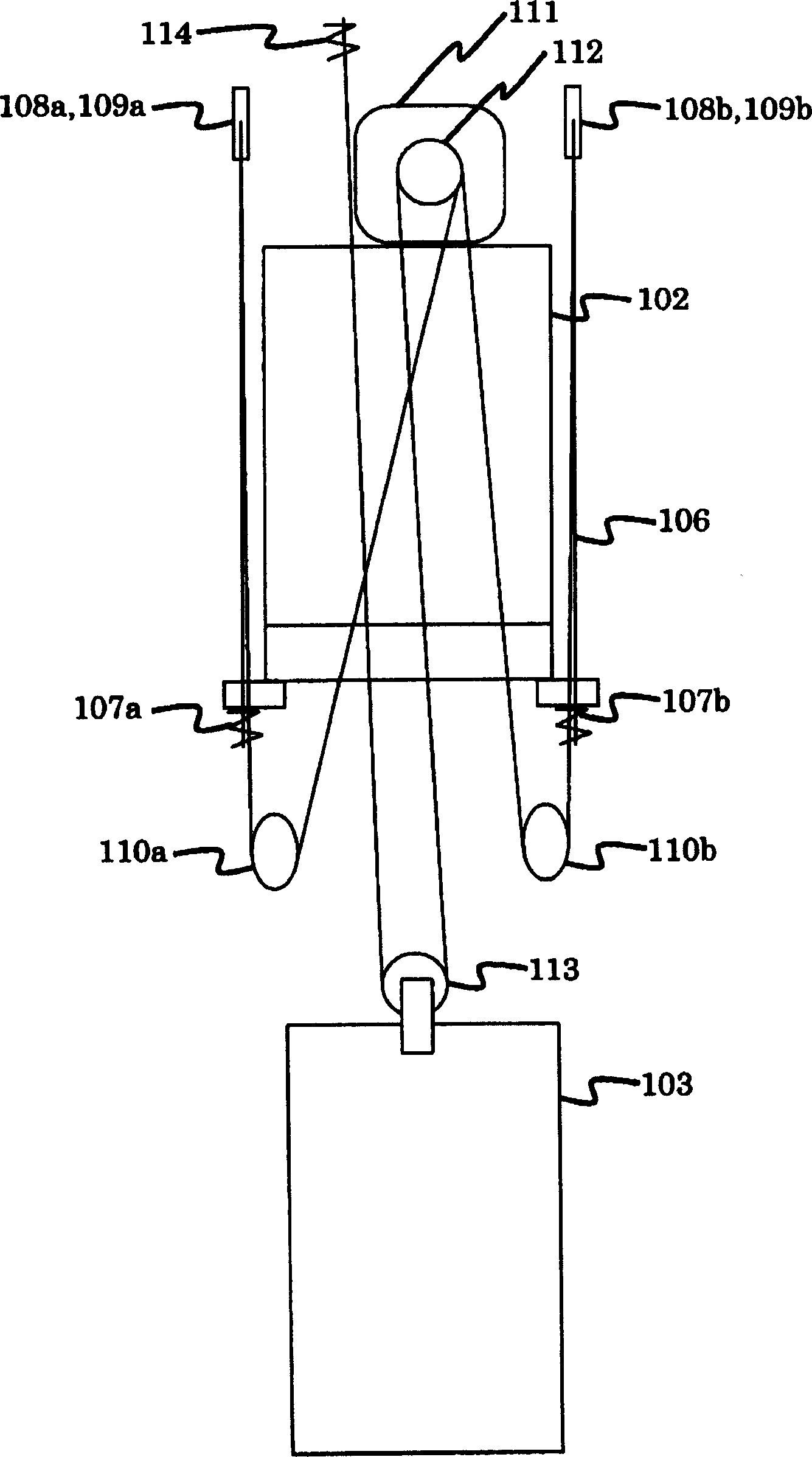

[0017] figure 1 It is a plan view of an elevator without a machine room according to an embodiment of the present invention, figure 2 for figure 1 main view.

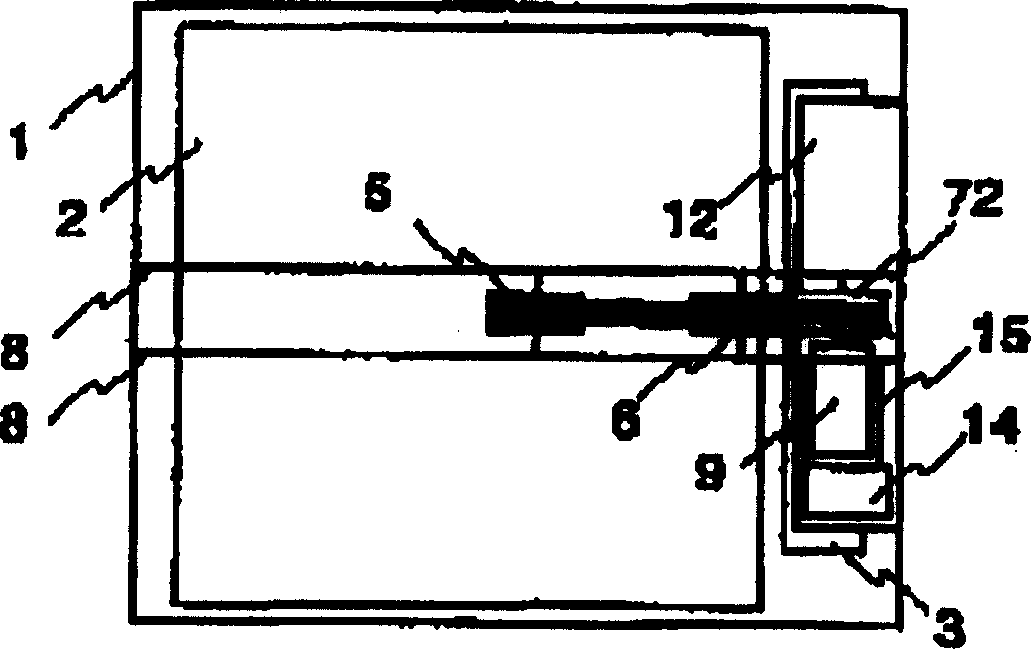

[0018] exist figure 1 and figure 2 , the elevator car 102 and the counterweight 103 move up and down in the hoistway 101 . A guide device (not shown) is installed above and below the sides of the elevator car 102 and the counterweight 103, and guided by the guide device, the elevator car 102 moves up and down along the elevator car guide rails 104a, 104b. Like the elevator car 102, the counterweight 103 smoothly moves up and down along the counterweight guide rails 105a, 105b in the hoistway without inclining the elevator car.

[0019] In addition, in the elevator car 102, the side portions near the center of gravity pass through fixed ropes 106a, 106b (one rop...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap