Steel pipe stake positioning and plumbing device for underground architecture

A technology for underground construction and steel pipe columns, which is applied in the construction, building structure, construction material processing and other directions, can solve the problems of difficult temperature change, increased cost, high noise in manual operation, etc. The effect of saving materials and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

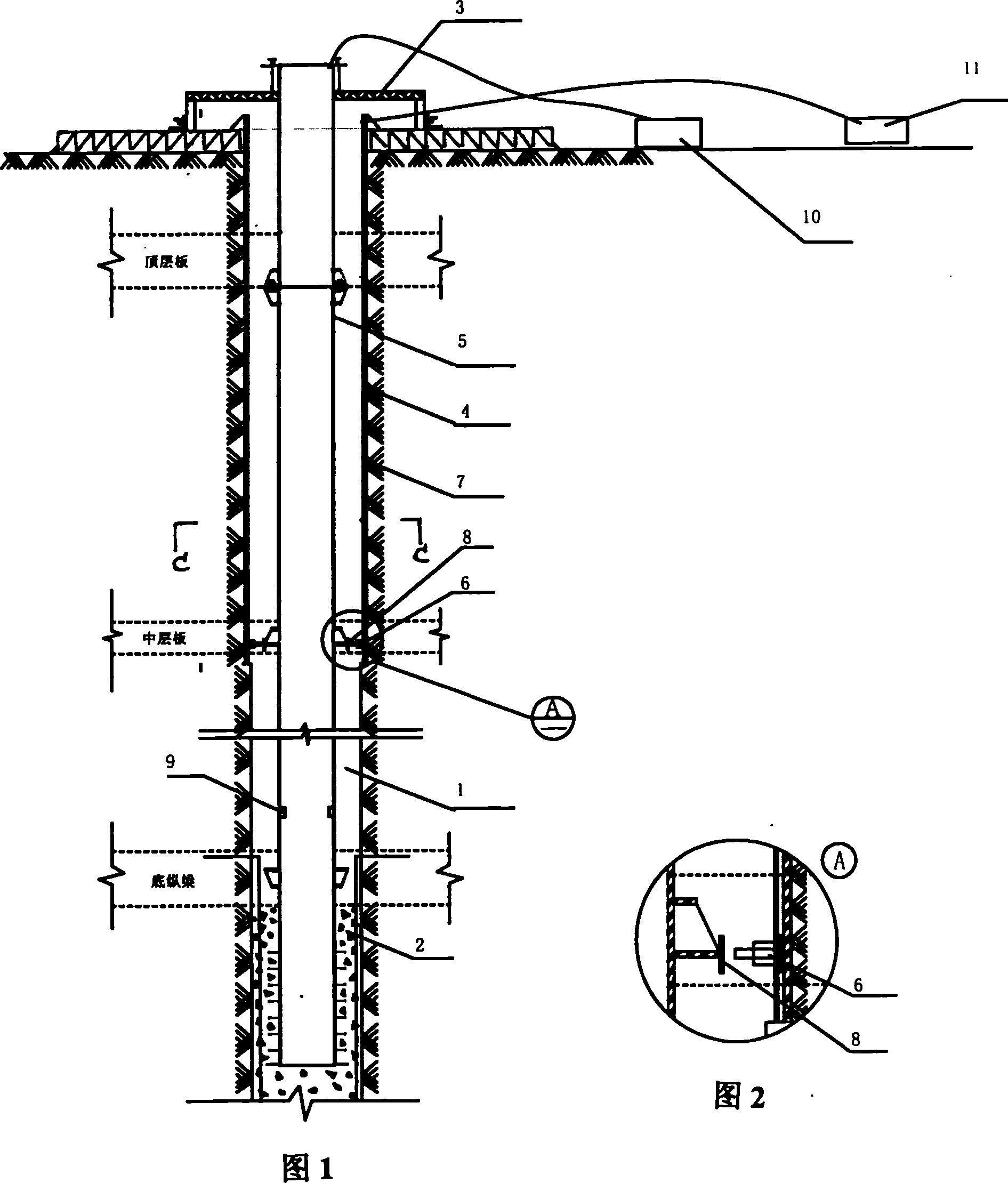

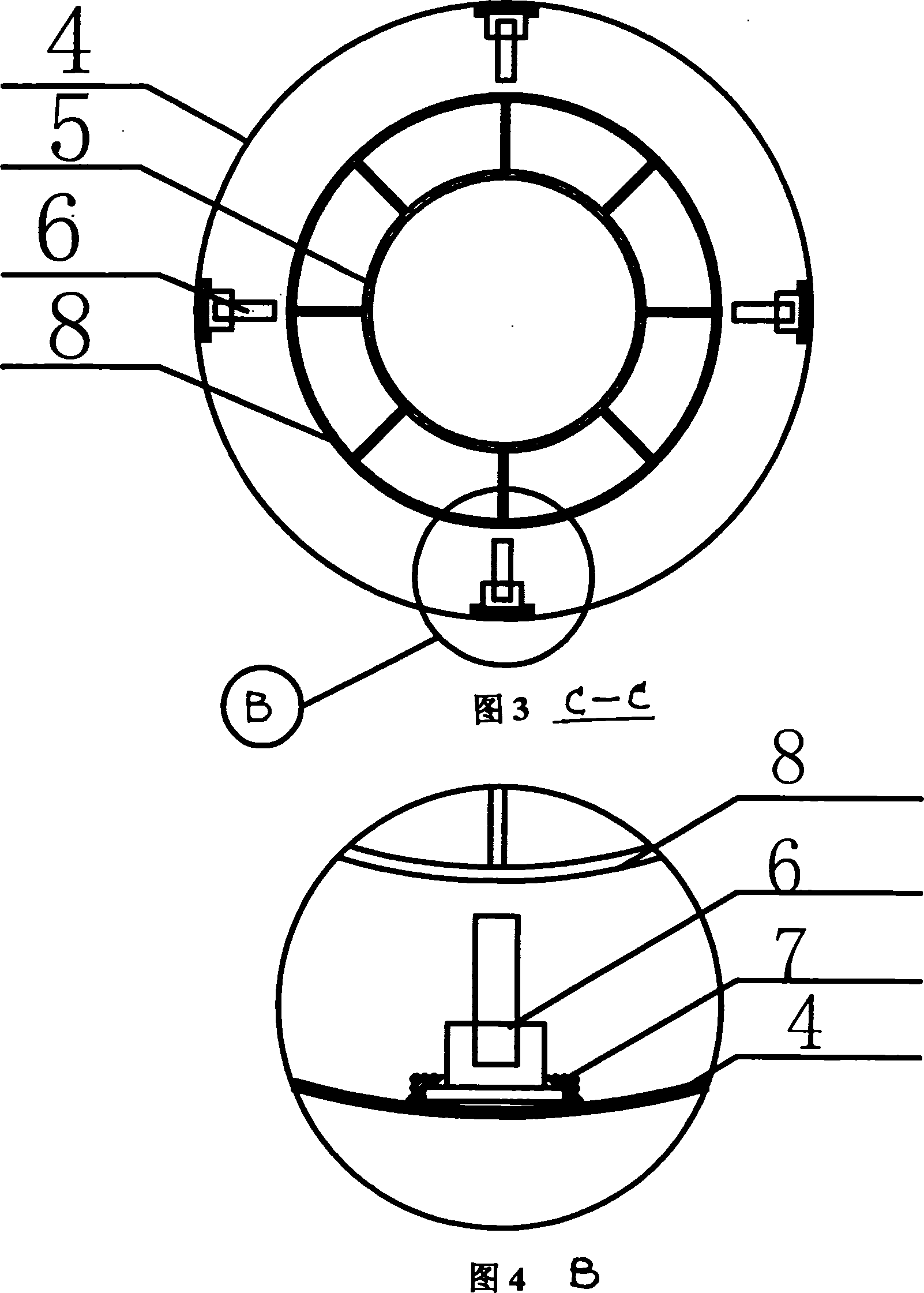

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0015] A steel pipe column positioning and vertical adjustment device for an underground building, which is composed of a ground positioning platform 3, a steel casing 4, a jack 6, a slideway 7, a steel pipe column 5, a steel enclosure 8, an inclinometer system, and a ground control system for jack vertical adjustment. The steel pipe column is placed in the steel casing, and a jack is provided between the steel casing and the steel pipe column. It is connected with the inclinometer display system 10, and the jack is connected with the vertical adjustment ground control system of the jack. The jack is controlled by the ground equipment, and the position of the lower end of the steel pipe column can be adjusted in any direction. The inner wall of the steel casing is provided with four slideways, and four s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com