High-gain waveguide trumpet array flat antenna

A flat-panel antenna and high-gain technology, applied in waveguide horns, antennas, antenna arrays, etc., can solve the problems of unfavorable antenna miniaturization, large waveguide antenna size, and difficult processing, and achieve weight reduction, good precision, and reduced manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

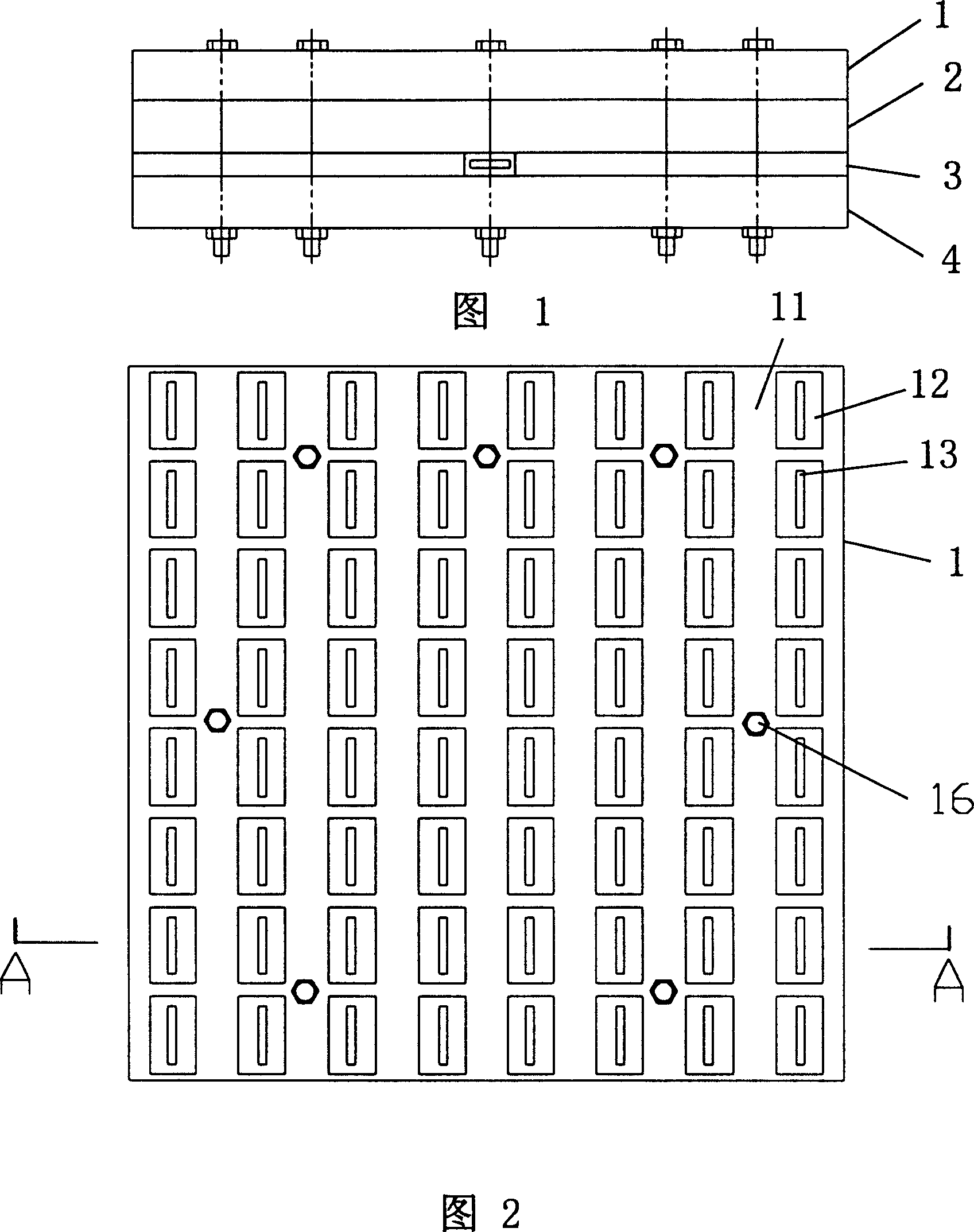

[0036] See Figure 1, Figure 16 , Figure 17 Shown: a high-gain waveguide horn array panel antenna, which includes a top layer conductive plate 1, a middle layer conductive plate 2, a strip line layer conductive plate 3, and a bottom layer conductive plate 4;

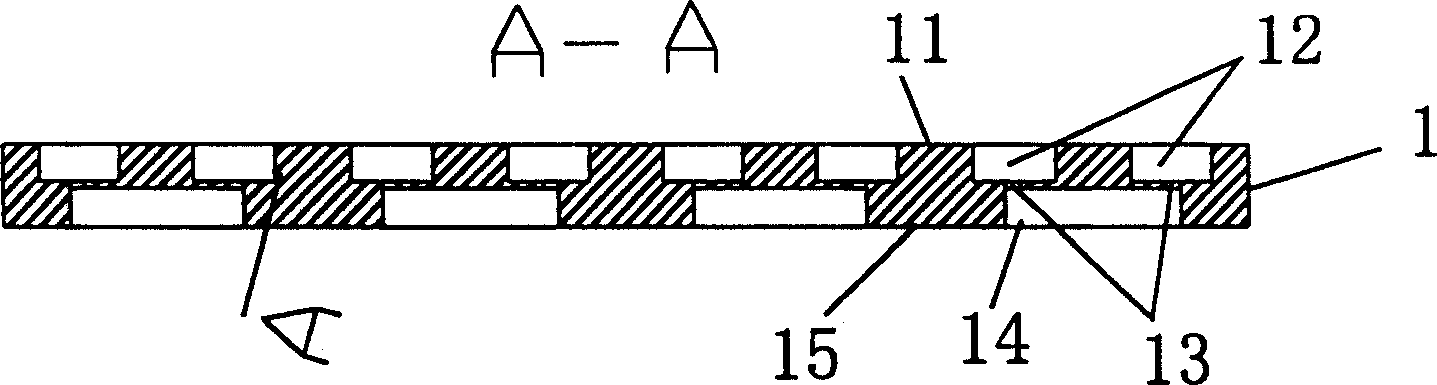

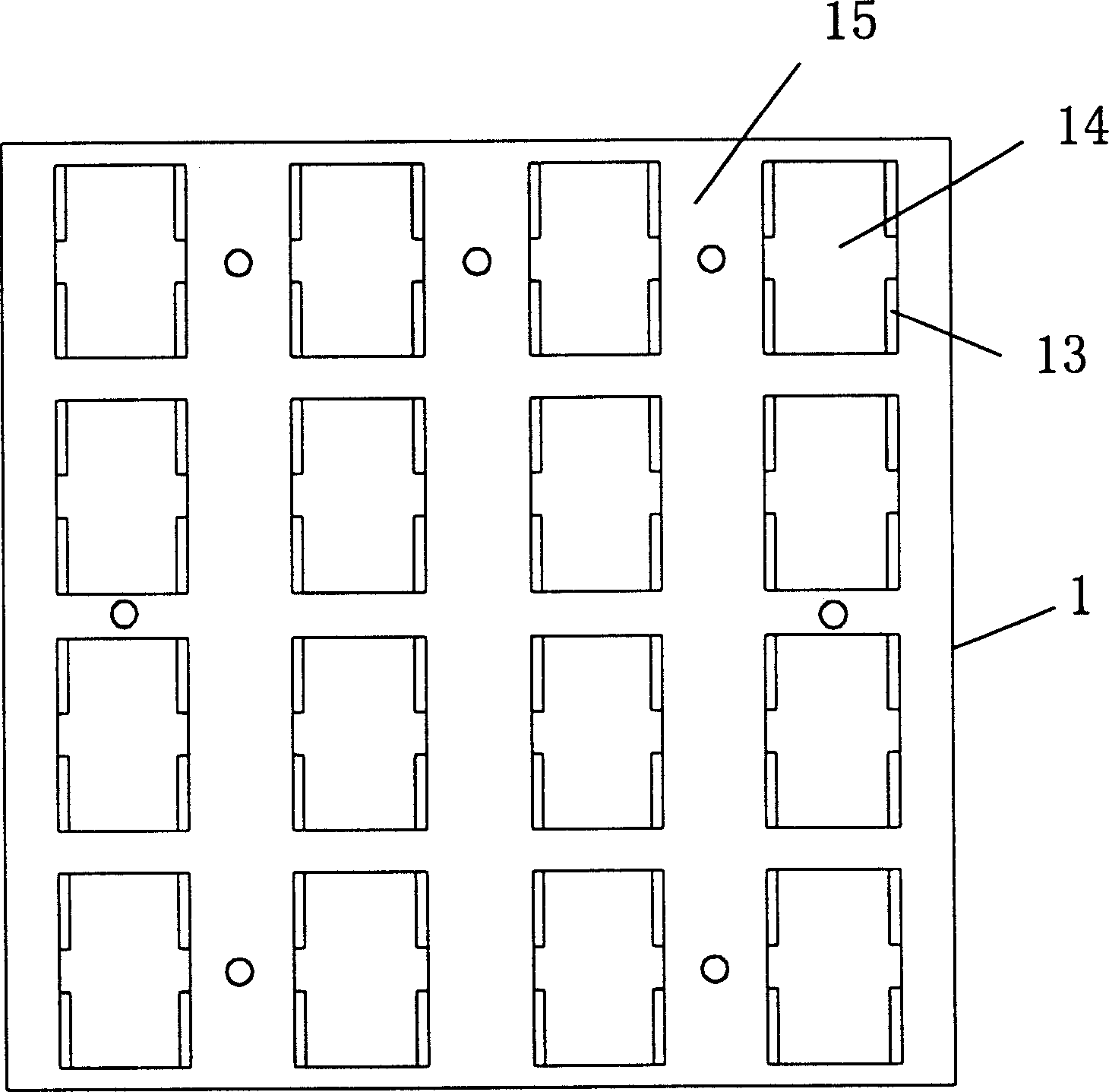

[0037] See Figure 2, image 3 , Figure 4 As shown: the upper surface of the top conductive plate 1 is provided with a plurality of horn holes 12 in an array, and a feeding slot through hole 13 is provided in the middle of the inner bottom of the horn holes 12, and in the lower surface 15 of the top conductive plate 1 The array is provided with a plurality of cavity-shaped conduits 14, and at the four corners of the cavity-shaped conduits 14 there are feeding slot through-holes 13 communicating with the four horn holes;

[0038] see Figure 5 , Figure 6, Figure 7, Figure 8 , Figure 9 As shown: the middle layer conductive plate 2 is arranged at the bottom of the top layer conductive plate 1, and a waveguide corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com