Process of removing and recovering CO2 from fume

A flue gas removal technology, applied in chemical instruments and methods, separation methods, through absorption, etc., can solve problems such as high consumption of absorbents and equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] components

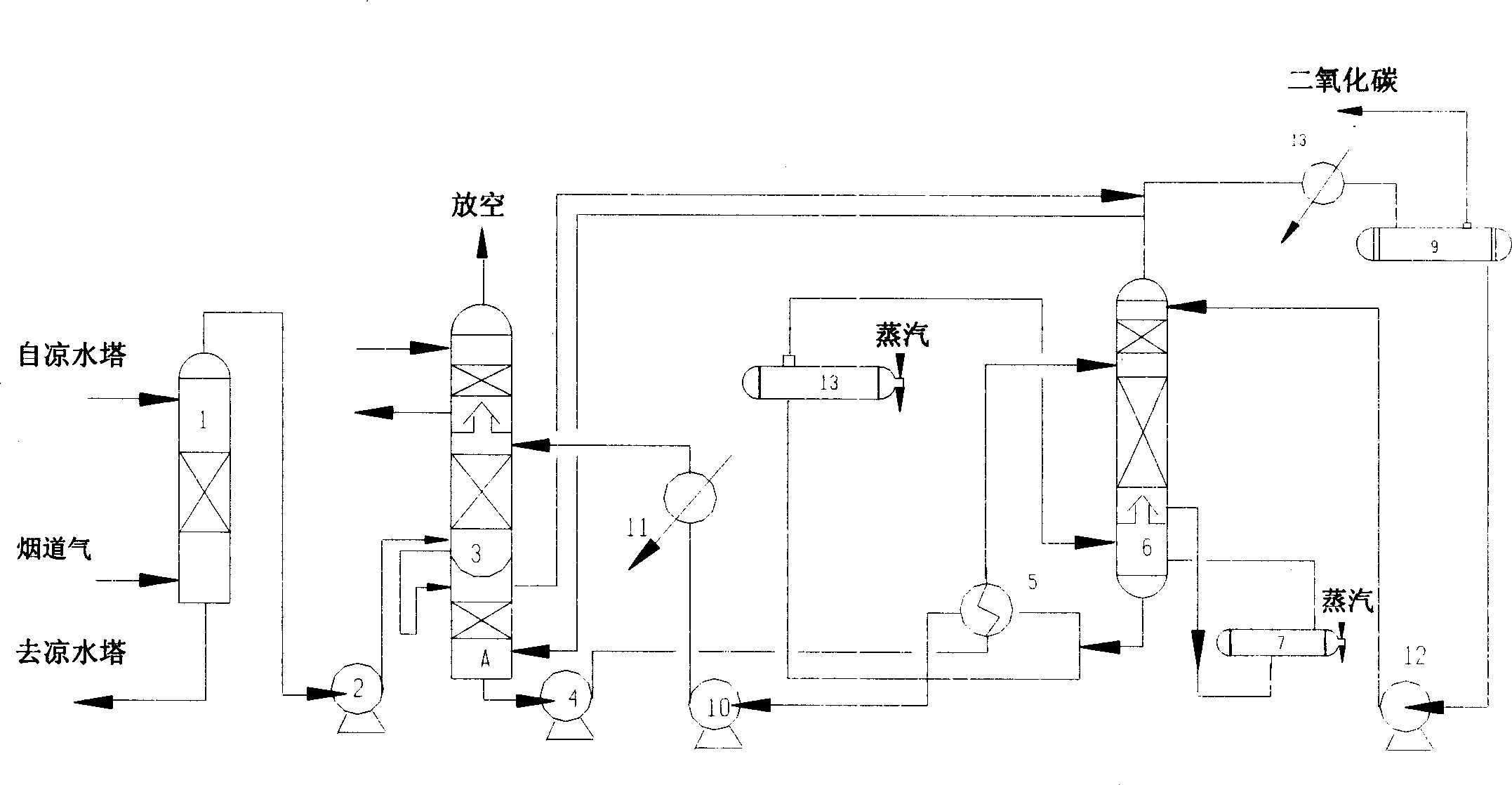

[0024] Under the same operating conditions, the figure 1 and Figure 4 A comparative experiment was carried out with the shown technological process. Experimental results show that compared with the conventional technology, the invention reduces the consumption of absorbent by 80%, and the corrosion rate of the carbon steel by the absorption liquid is reduced by 90%.

Embodiment 2

[0026] The gas source is the same as in Example 1.

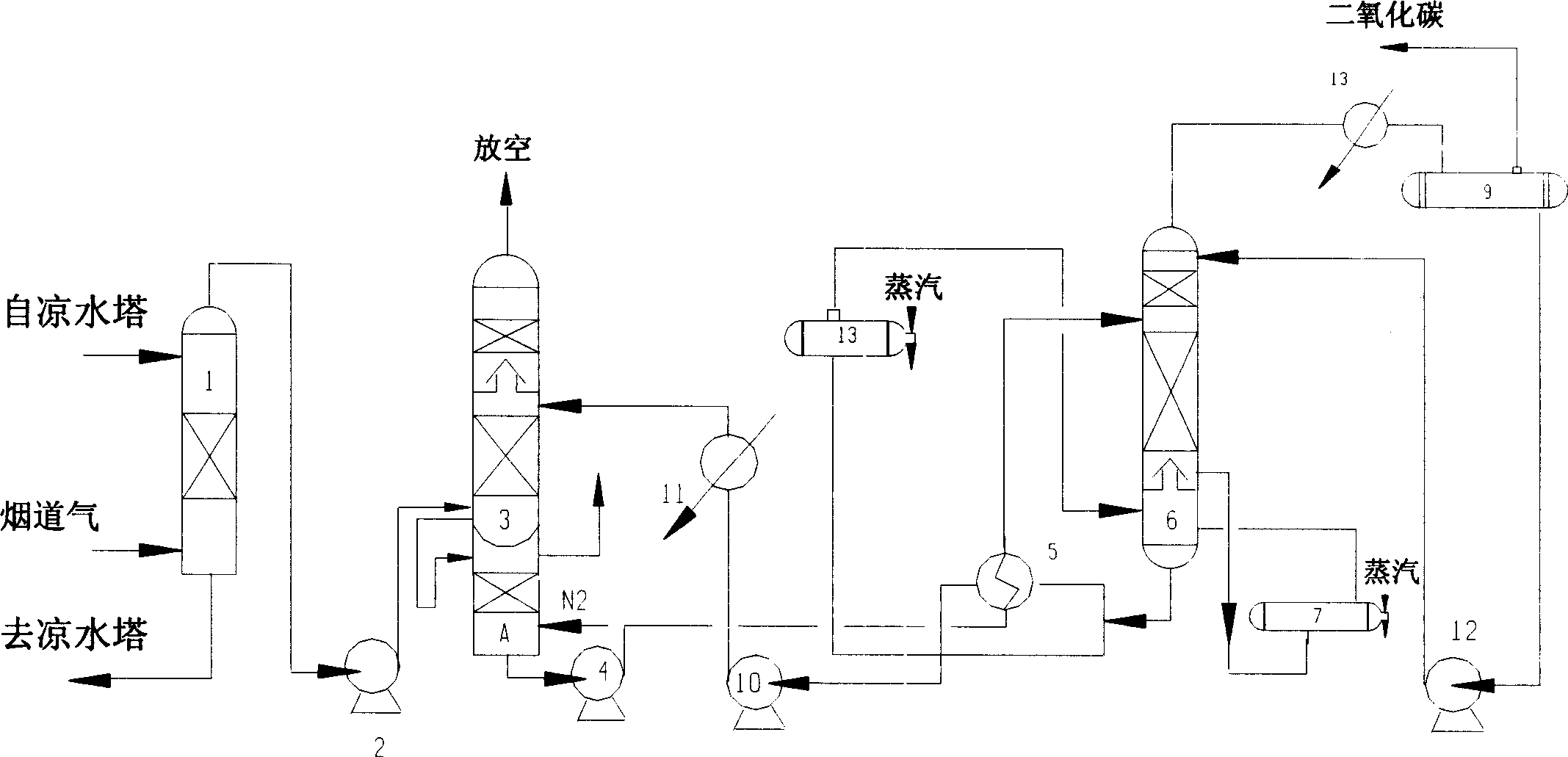

[0027] Under the same operating conditions, the figure 2 and Figure 4 A comparative experiment was carried out with the shown technological process. Experimental results show that the present invention reduces the consumption of absorbent by 80% compared with the conventional process, and the corrosion rate of carbon steel by the absorption liquid is reduced by 90%, and the product CO 2 CO, SO in air 2 , NOx, O 2 The total content was reduced by 83%.

Embodiment 3

[0029] components

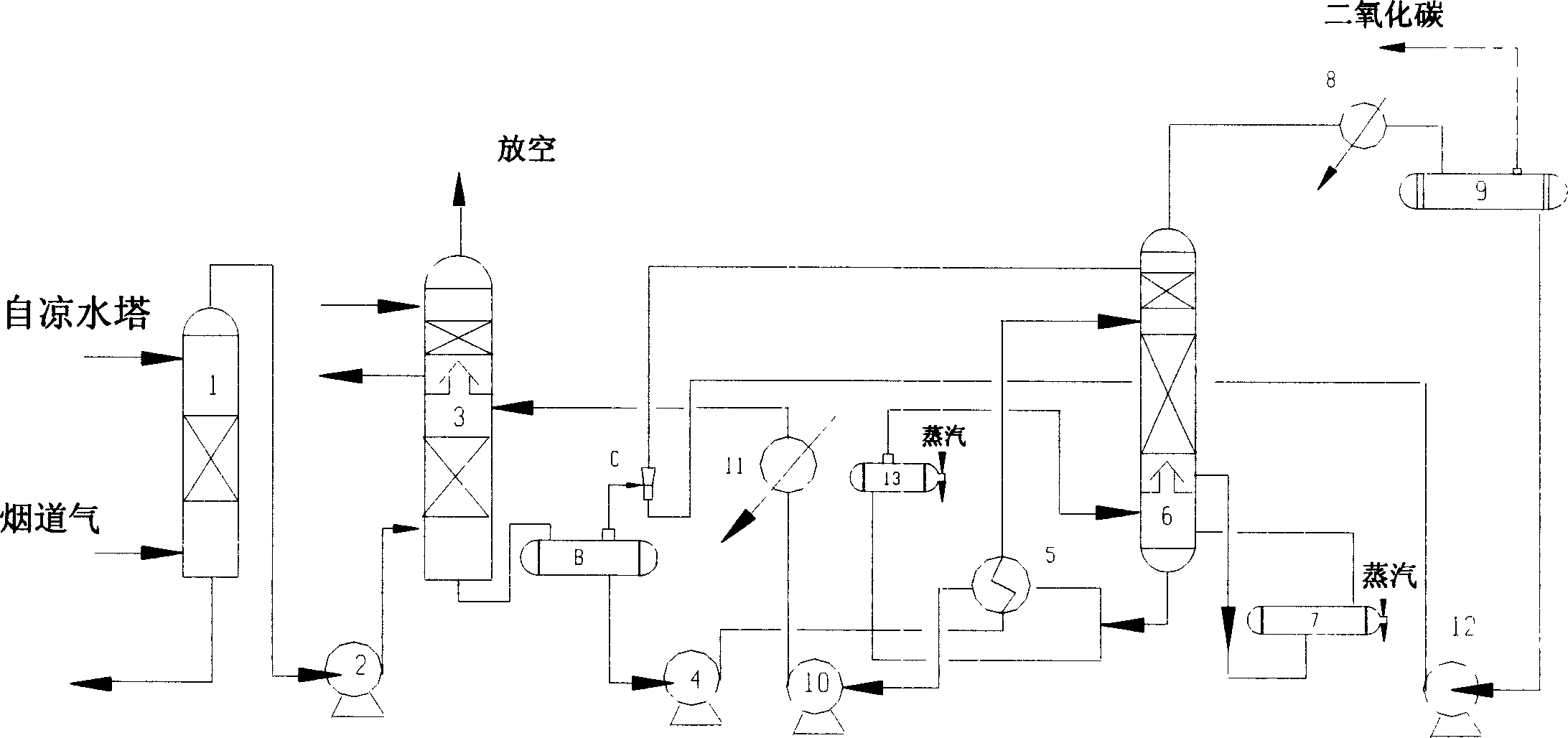

[0030] Under the same operating conditions, the image 3 and Figure 4 A comparative experiment was carried out with the shown technological process. Experimental results show that compared with the conventional technology, the invention reduces the consumption of absorbent by 78%, and the corrosion rate of the carbon steel by the absorption liquid is reduced by 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com