Drilling bit for borehole pump pouring large flowing concrete and guniting enlarging footing piling

A large flow, drilling pump technology, applied in the direction of drill bits, sheet pile walls, drilling equipment, etc., can solve the problems of unreasonable force structure and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

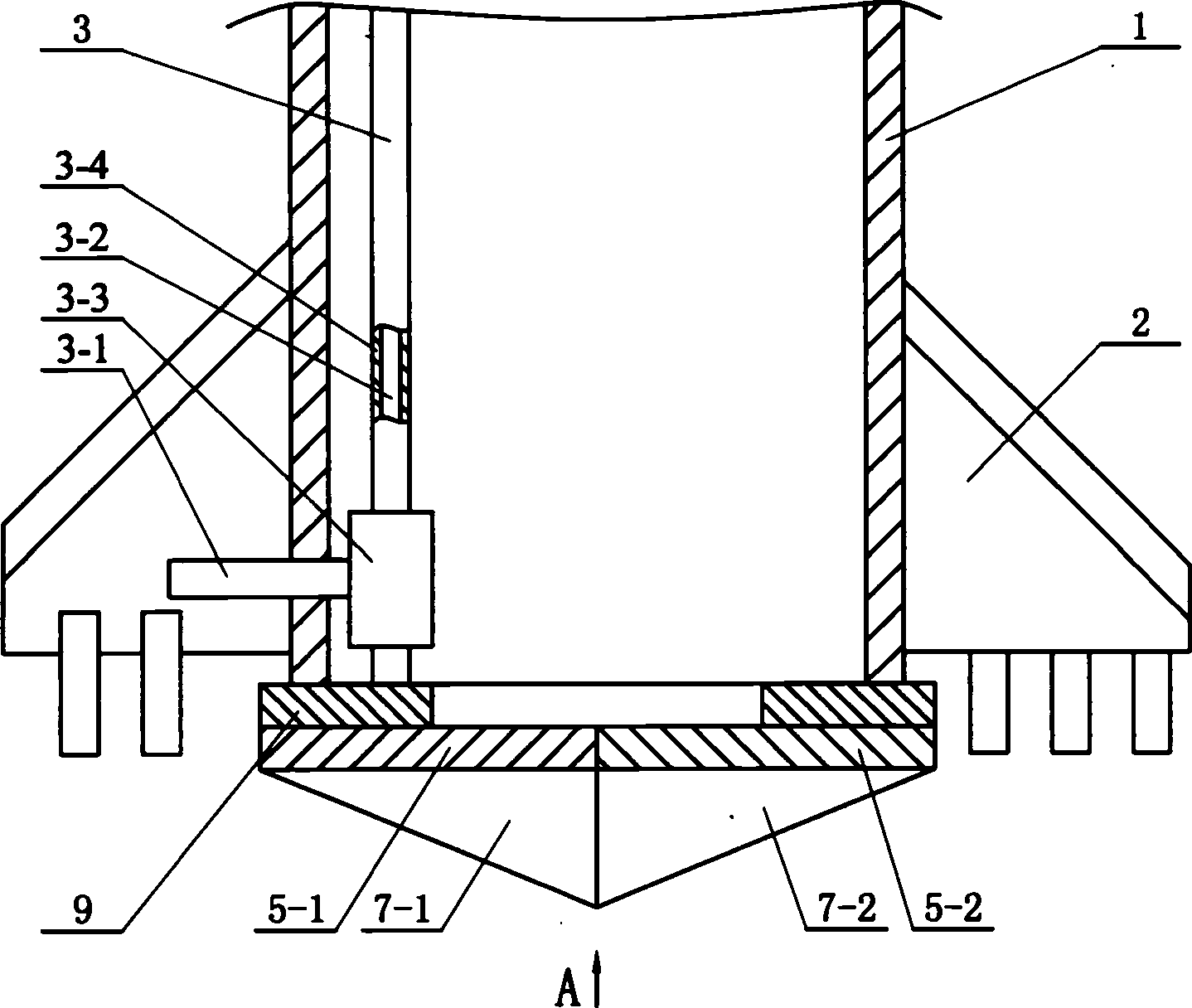

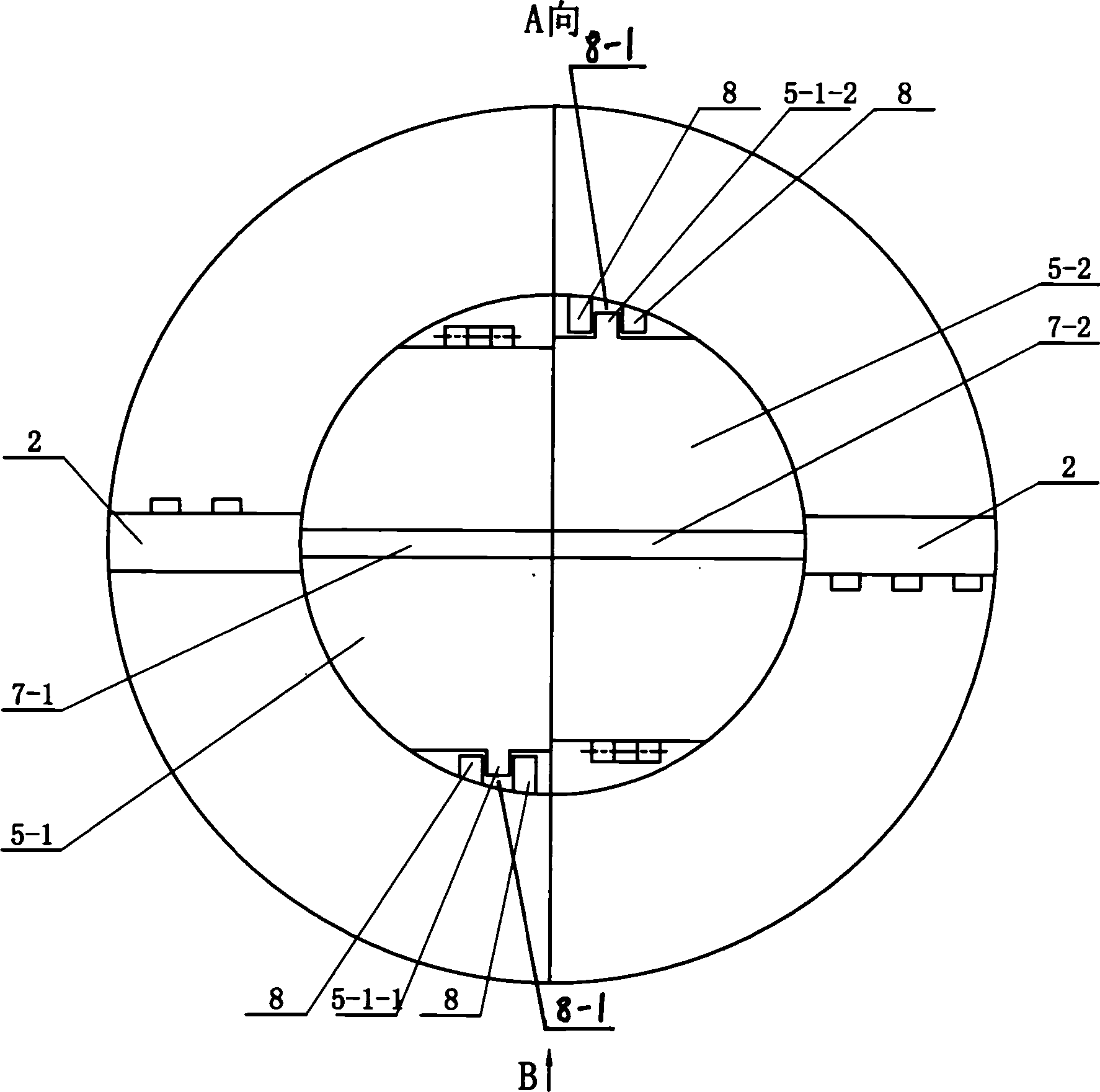

[0005] Specific implementation mode one: the following combination figure 1 and figure 2 This embodiment will be specifically described. This embodiment consists of a cylindrical drill pipe 1, a blade 2 fixed on the outer surface of the drill pipe 1, a shot channel 3 arranged in the drill pipe 1, a left valve plate 5-1, a right valve plate 5-2, a left half The drill point 7-1 and the right half drill point 7-2 are formed, the left valve plate 5-1 is hinged on the bottom end of the drill rod 1 and the left half of the bottom end of the drill rod 1 is closed, and the right valve plate 5-2 is hinged on the drill rod 1. On the bottom of the rod 1 and the right half of the bottom of the drill rod 1 is closed, the left half of the drill point 7-1 is fixed on the lower surface of the left valve plate 5-1, and the right half of the drill point 7-2 is fixed on the right valve plate 5 On the lower surface of -2, the side is that the left half of the drill point 7-1 and the right half...

specific Embodiment approach 2

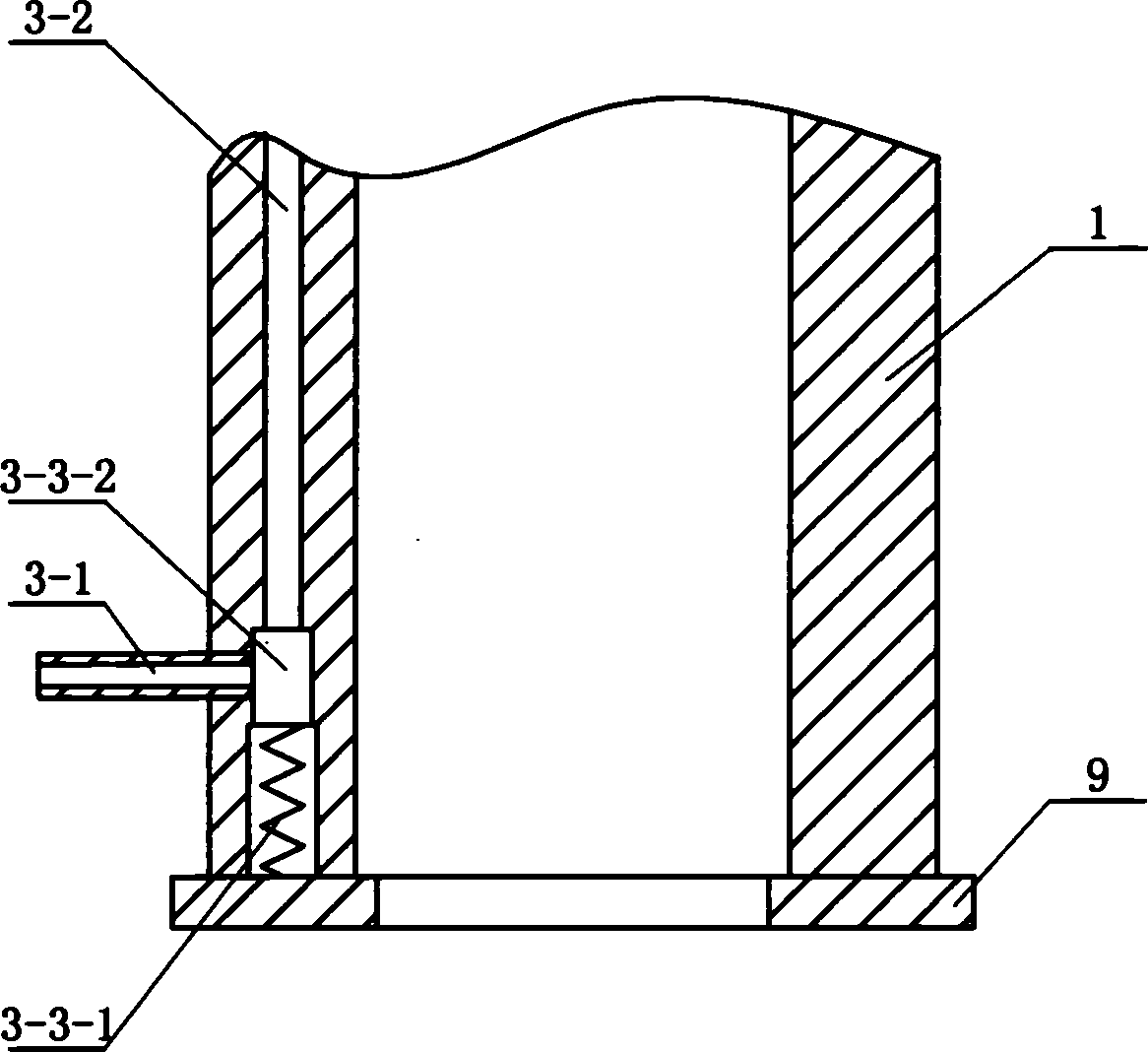

[0006] Specific implementation mode two: the following combination image 3 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is: the check valve 3-3 is composed of a spring 3-3-1 and a slider 3-3-2, and the slider 3-3-2 is arranged in the down passage 3-2 , the side surface of the slider 3-3-2 is blocked on one end of the nozzle 3-1, and a spring 3-3-1 is arranged under the slider 3-3-2. During the work of the present embodiment, the descending cement grout makes the slide block 3-3-2 descend, the spring 3-3-1 is compressed, and the cement grout is ejected from the nozzle 3-1. Work ends, because there is no pressure of cement grout, spring 3-3-1 is elongated, and slide block 3-3-2 is blocked an end of nozzle 3-1, and grout can not retrograde. Other composition and connection modes are the same as those in Embodiment 1.

specific Embodiment approach 3

[0007] Specific implementation mode three: the following combination image 3 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that: the down channel 3 - 2 is opened in the pipe wall of the drill pipe 1 . With such arrangement, the structure is relatively simple and the cost is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com