Amorphous alloy strain gauge

A technology of amorphous alloys and strain gauges, which is applied in the direction of force measurement by measuring the change of magnetic properties of materials caused by applied stress. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

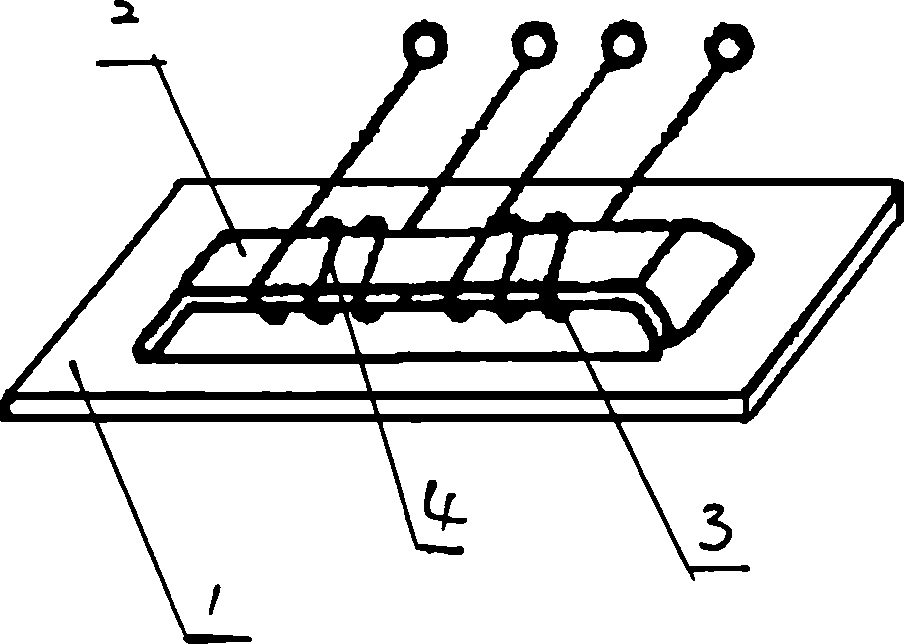

[0008] An amorphous alloy strain gauge, the middle part of the amorphous alloy thin strip 1 protrudes to one side to form an arch bridge-shaped magnetic pole 2, the bridge surface of the magnetic pole 2 is arranged parallel to the main body of the amorphous alloy thin strip 1, and the magnetic pole 2 protrudes The height is h, 0<h<0.5mm, the smaller the value, the better to reduce the additional bending moment. An exciting coil 4 and a measuring coil 3 are wound side by side on the magnetic pole 2 . At this time, the raised portion corresponds to the coil core. The specific size of the strain gauge is mainly determined by the allowable stress of the selected amorphous alloy material. At present, the specifications of the amorphous alloy thin strips provided by Antai Technology Co., Ltd. in China are: width 5-100mm, thickness 0.03mm, the length can be cut according to needs, and users can also customize special specifications according to needs. When the tensile stress is mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number of turns | aaaaa | aaaaa |

| Number of turns | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com