Liquid-filling compressing method for testing metal deformation flow

A technology of metal deformation and compression method, which is applied in the field of inspection, can solve the problems that the stress state of the deformed body cannot be directly given, and the influence of metal deformation and flow cannot be studied, so as to achieve the effect of a reliable inspection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

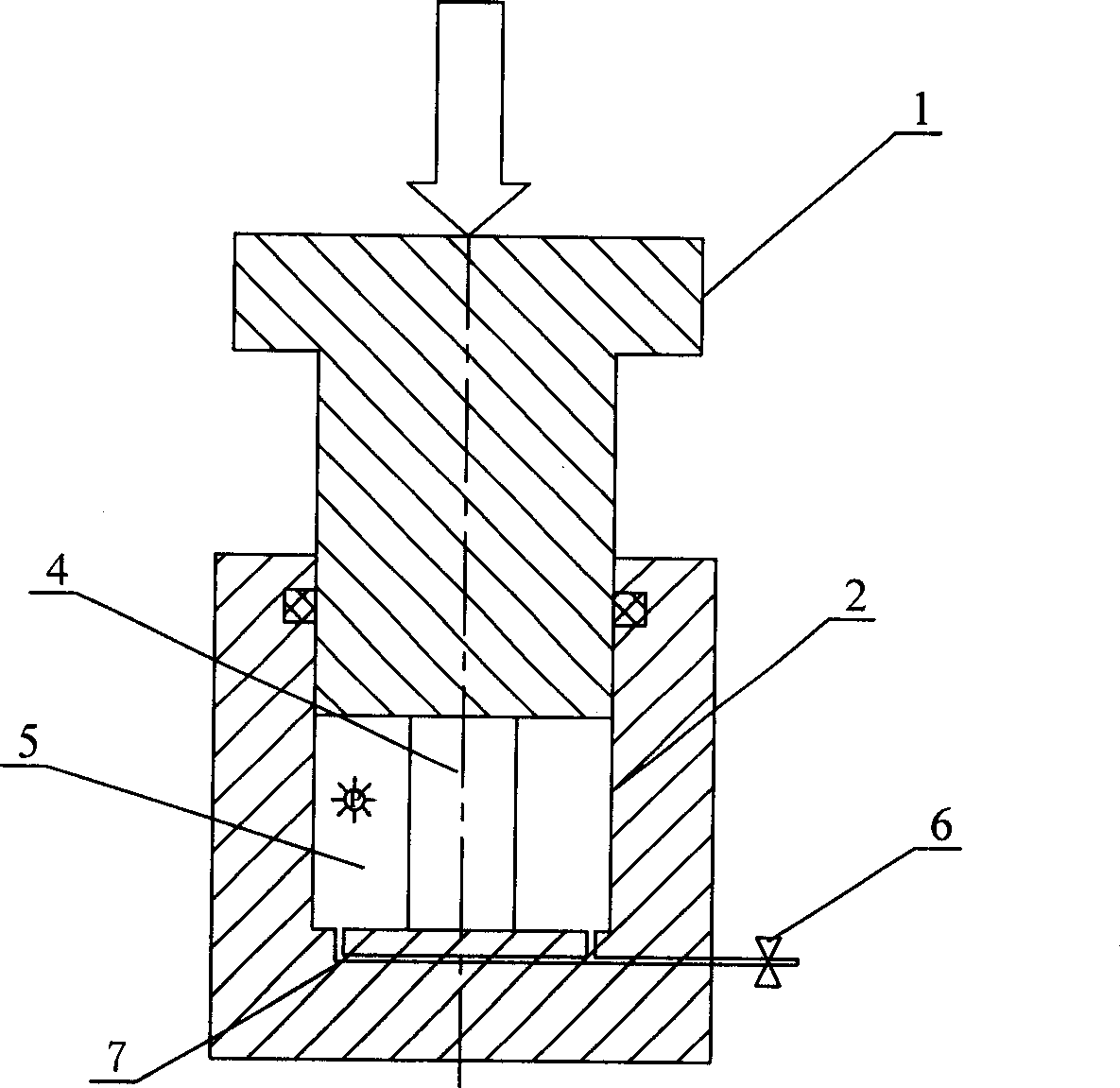

[0012] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 Illustrate this embodiment, its inspection process comprises the following steps:

[0013] Step 1: Record the raw data of the cylindrical sample 4;

[0014] Step 2: Put the cylindrical sample 4 into the liquid-filled chamber 2;

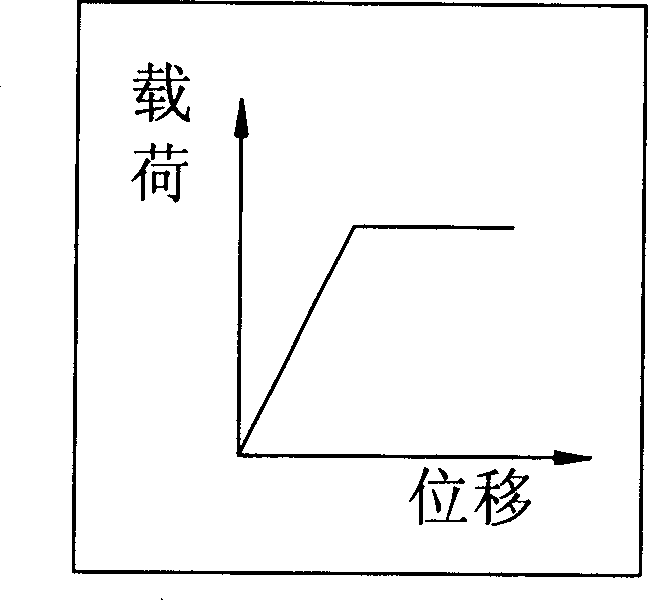

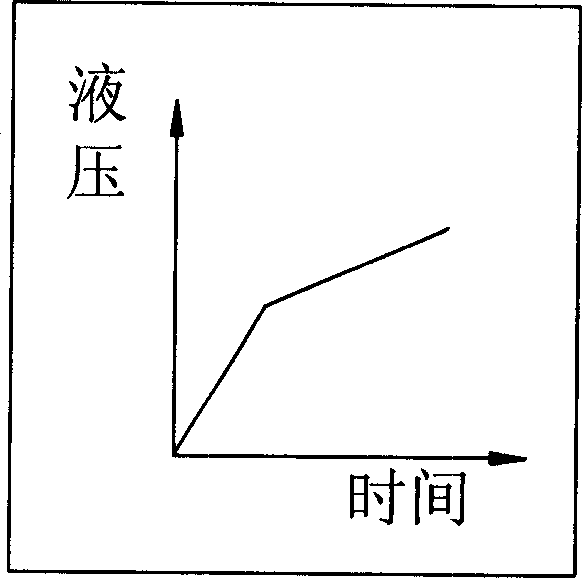

[0015] Step 3: The punch 1 is pressed down, so that the cylindrical sample 4 in the liquid-filled chamber 2 receives the axial principal stress, and at the same time, the high-pressure medium 5 around the cylindrical sample 4 in the liquid-filled chamber 2 is also punched. The volume change brought about by the pressing down of the head 1 causes the hydraulic pressure to change, and the hydraulic pressure is adjusted so that any point in the cylindrical sample 4 always obtains the same transverse principal stress during the pressing down process, reaching the pre-designed hydraulic pressure and press load, making the cylindrical sample 4 compressively def...

specific Embodiment approach 2

[0018] Specific implementation mode two: in conjunction with Fig. 5, Figure 6 , Figure 7 , Fig. 8 illustrates the present embodiment, and its inspection process comprises the following steps:

[0019] Step 1: Record the raw data of the annular sample 3;

[0020] Step 2: Put the circular sample 3 into the middle of the liquid-filled chamber 2;

[0021] Step 3: The punch 1 is pressed down, so that the annular sample 3 in the liquid-filled chamber 2 obtains the axial principal stress, and at the same time, the high-pressure medium 5 around the annular sample 3 in the liquid-filled chamber 2 also The volume change caused by the pressing of the punch 1 causes the hydraulic pressure to change, and the hydraulic pressure is adjusted so that any point in the annular sample 3 can always get the same transverse principal stress during the pressing process, reaching the pre-designed hydraulic pressure and pressure. machine load, so that the annular sample 3 is compressed and deforme...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 , figure 2 , image 3 , Figure 4 This embodiment is described. The difference between this embodiment and the first embodiment is that the adjustment of the hydraulic pressure in the third step is to use the pipeline 7, the control valve 6 and the external hydraulic control equipment to adjust the hydraulic pressure of the high-pressure medium 5 . Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com