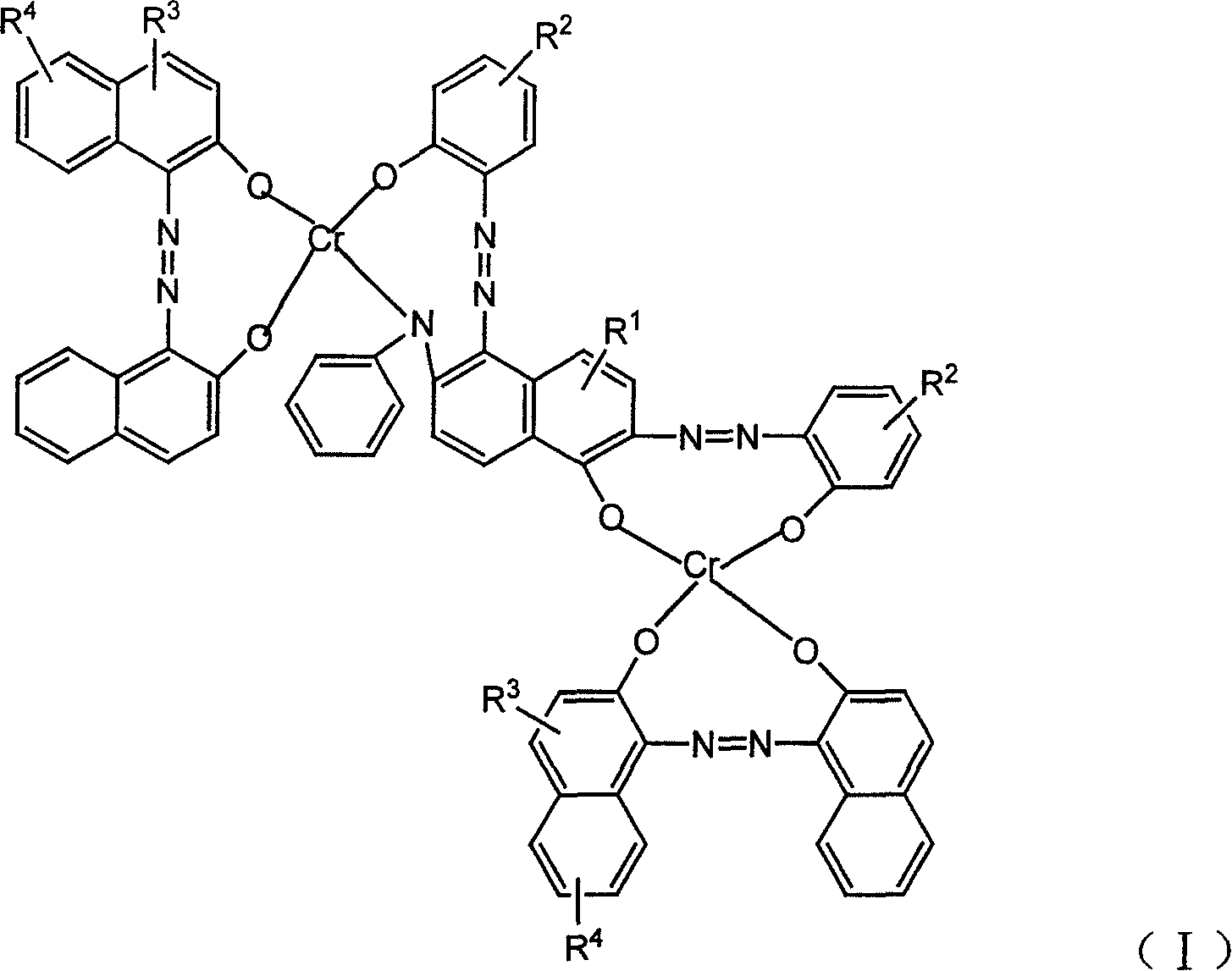

Azo-group metal complex dye, and its preparing method

A technology of complex dyes and base metals, used in azo dyes, complex metal compounds of azo dyes, organic dyes, etc. Excellent light and wet fastness, high color fixing rate, simple and reliable dyeing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

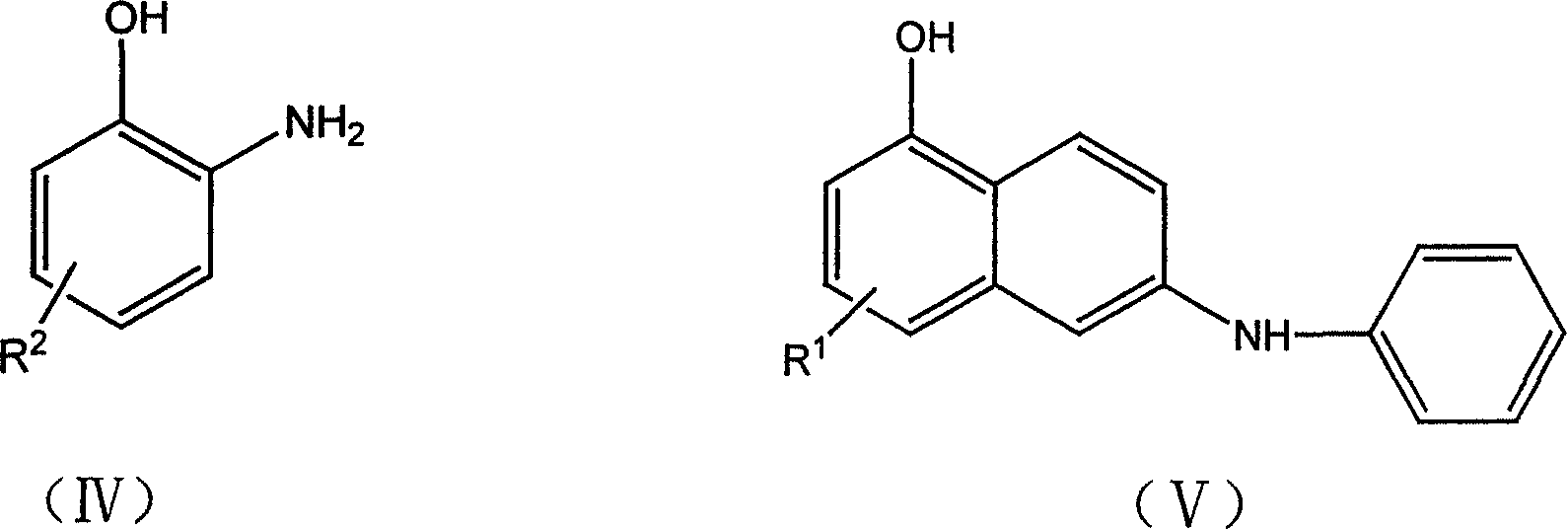

[0022] In the first step, the 6-nitro-1,2,4-acid oxygen body is coupled with 2-naphthol:

[0023] Add 20 grams of 6-nitro-1,2,4-acid oxygen, as shown in (VI-a), add 60 ml of water to make a slurry, add ice and cool to 8 ° C, and adjust the pH of the feed solution with 10 ml of 30% liquid caustic soda Values up to Congo red do not appear blue. Add 10.5 grams of 2-naphthol to 7ml of water, add 8.5ml of 30% liquid caustic soda, heat up to 80°C to dissolve 2-naphthol, cool the solution to 30°C, and then flow into the above 6- In the nitro-1,2,4-acid oxygen body solution, under vigorous stirring, raise the temperature to 40°C within 1 hour, adjust the pH value to 8.5 with hydrochloric acid to carry out the coupling reaction, after the reaction, filter, wash with water, and dry , 26 grams of dry product of the coupled compound shown in the following formula (VII-a) were obtained.

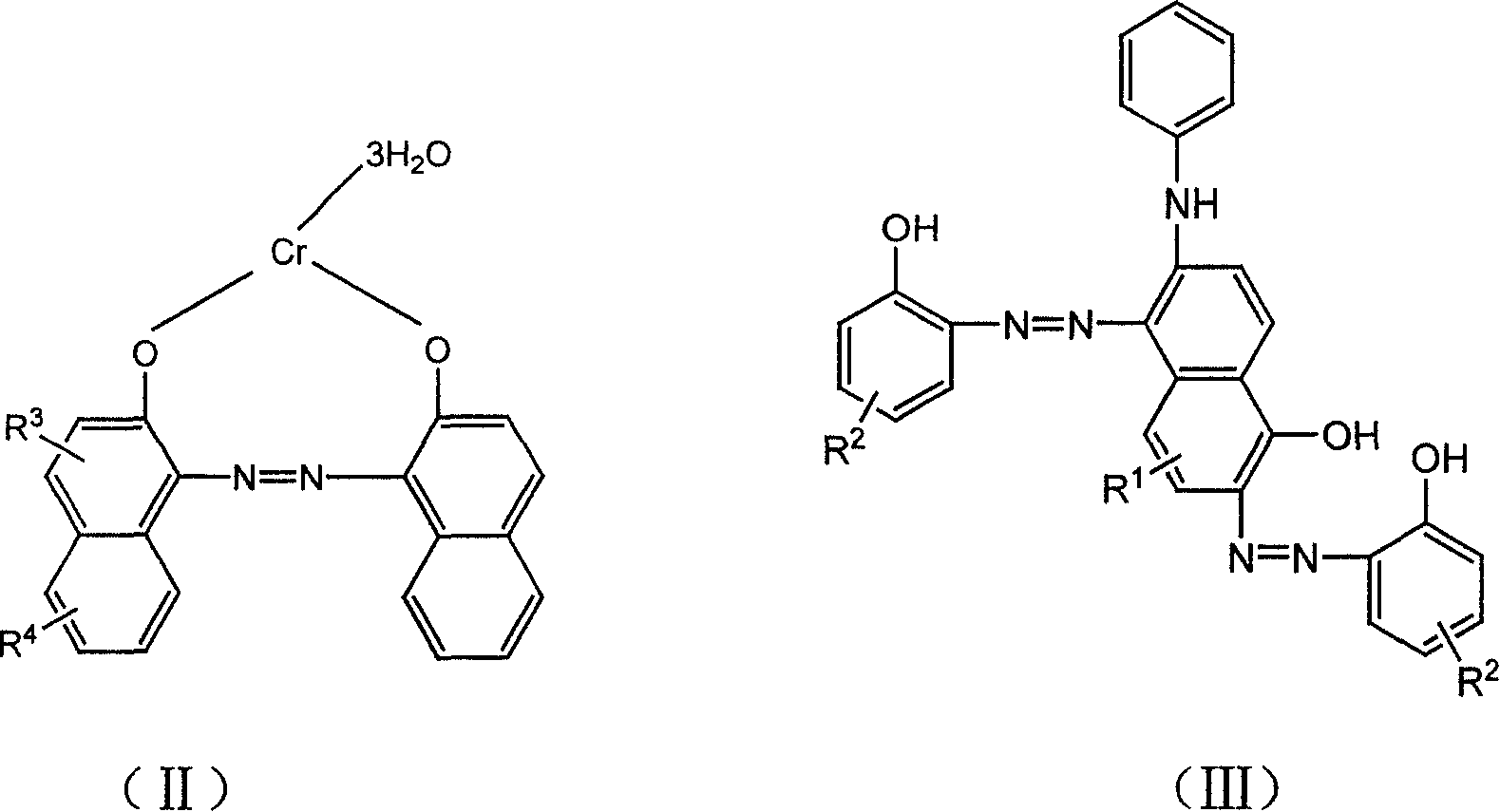

[0024] In the second step, the coupling compound prepared in the first step is complexed with chro...

Embodiment 2

[0035] Prepare according to the same method as in Example 1, except that the following formula (VI-b) is used instead of the above (VI-a), and the monoazo compound of formula (VII-b) and formula (II-b) are successively prepared. Chromium complex, azo metal complex acid black dye of formula (I-b).

[0036]

[0037]

Embodiment 3~10

[0039] According to the preparation method of Example 1, using the monoazo complexes and disazo compounds listed in Table 1 below, azo metal complex acid black dyes with corresponding structures were prepared.

[0040] Example

monoazo complex

Azo compounds

[0041]

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com