Plastic shuttering for building engineering poured door-window frame

A technology for construction engineering and plastic formwork, applied in construction, building structure, formwork/formwork components, etc., can solve problems such as nail deformation, and achieve the effects of improved work efficiency, convenient and simple disassembly, and reduced construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

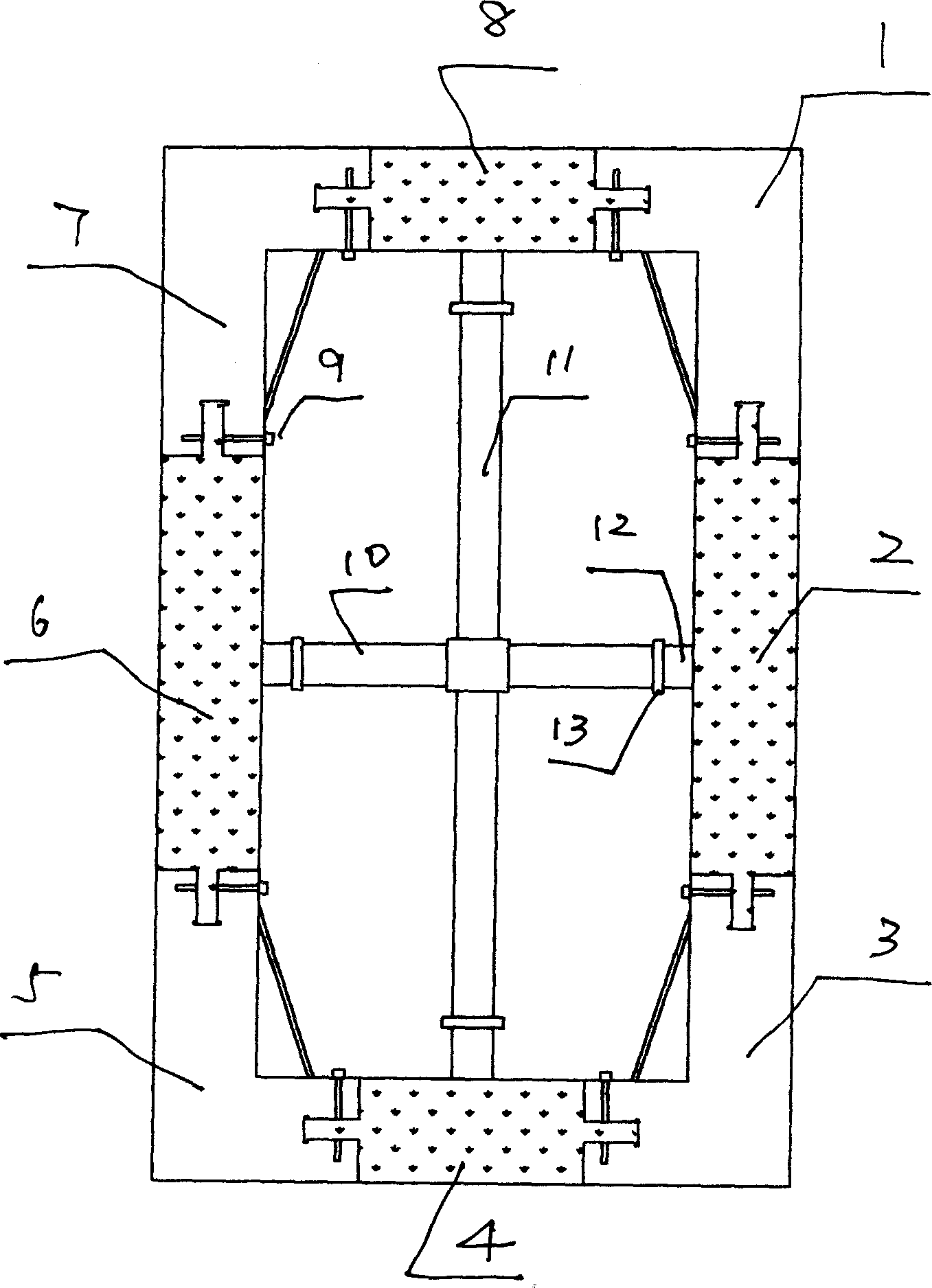

[0012] As shown in Figure 1: right-angle block 1, adjustment block 2, right-angle block 3, adjustment block 4, right-angle block 5, adjustment block 6, right-angle block 7, adjustment block 8, bolt 9, horizontal support rod 10, vertical support rod 11 , adjusting rod 12, fastening nut 13 are connected to form.

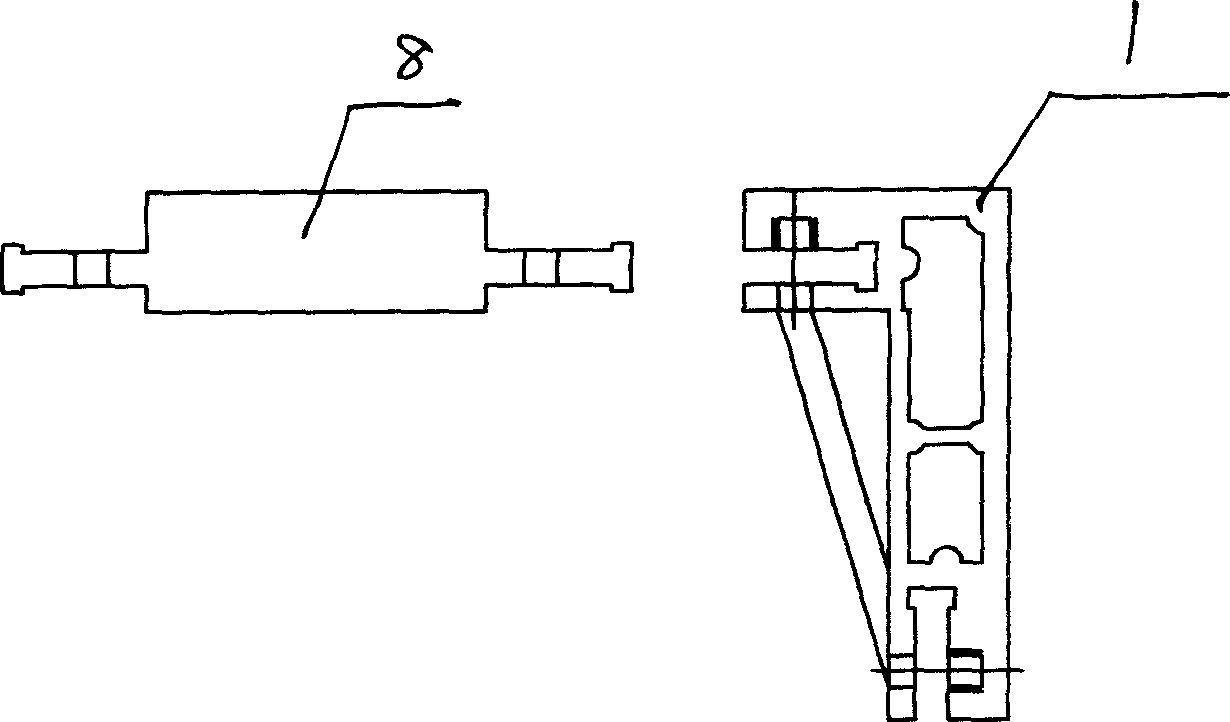

[0013] exist figure 2 In the illustration shown, the protruding parts at both ends of the adjustment block are connected with the concave parts of the right-angle block; fix it with screws after a little adjustment.

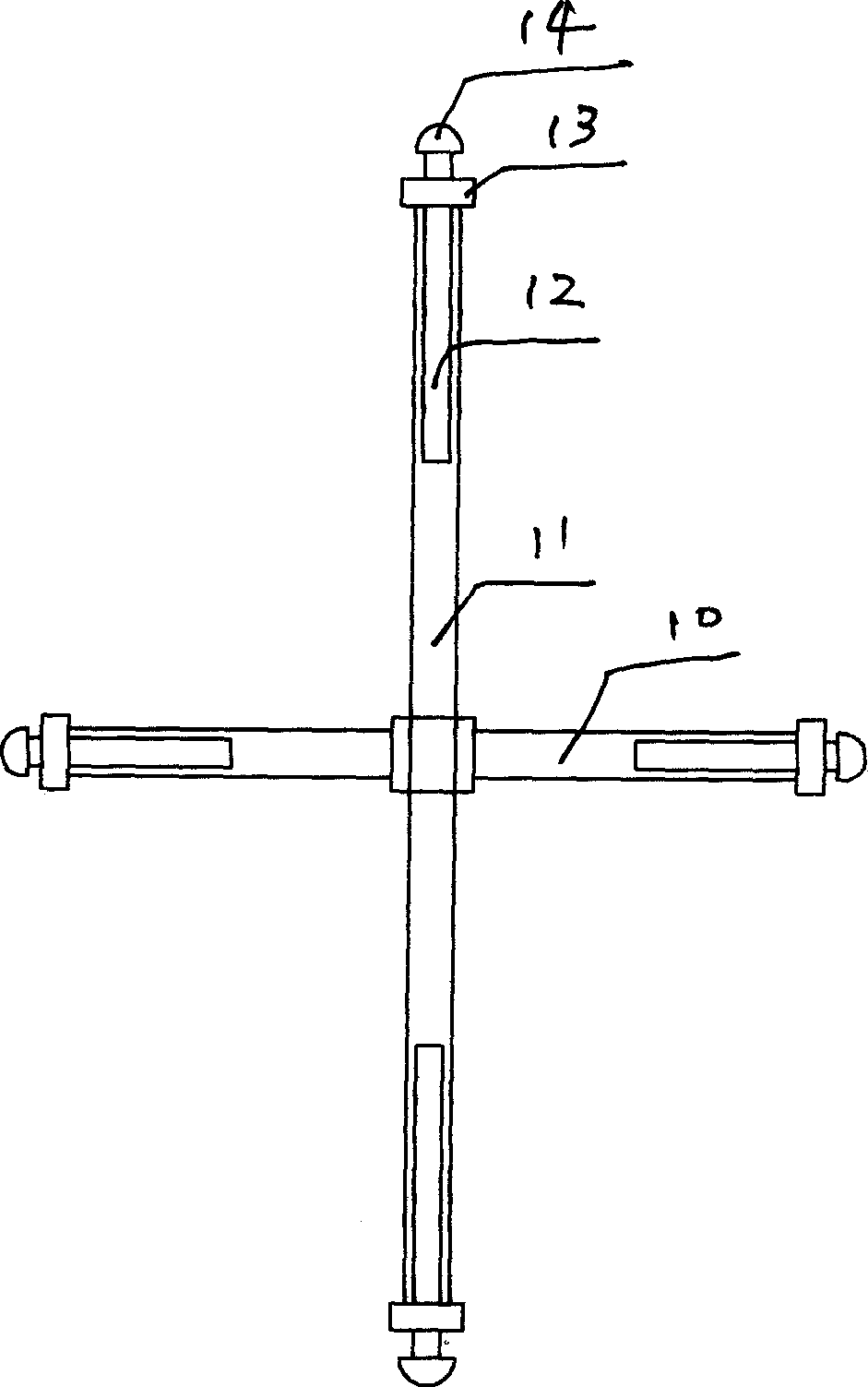

[0014] exist image 3 In the illustrated illustration, the two ends of the horizontal support rod 10 and the vertical support rod 11 are provided with an adjustment rod 12 , a fastening nut 13 and a plug 14 . By adjusting the length of the adjustment rod 12, the top 14 on the two ends of the horizontal support rod 9 and the vertical support rod 10 is pressed against the adjustment block, and the adjustment rod 12 is fixed with the fastening nut 13 afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com