Radiating module and its housing

A heat dissipation module and shell technology, applied in cooling/ventilation/heating transformation, instrument cooling, instrument, etc., can solve problems such as dead angle, dust accumulation, material limitation, etc., to save production and processing costs, selectivity more Flexible, highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

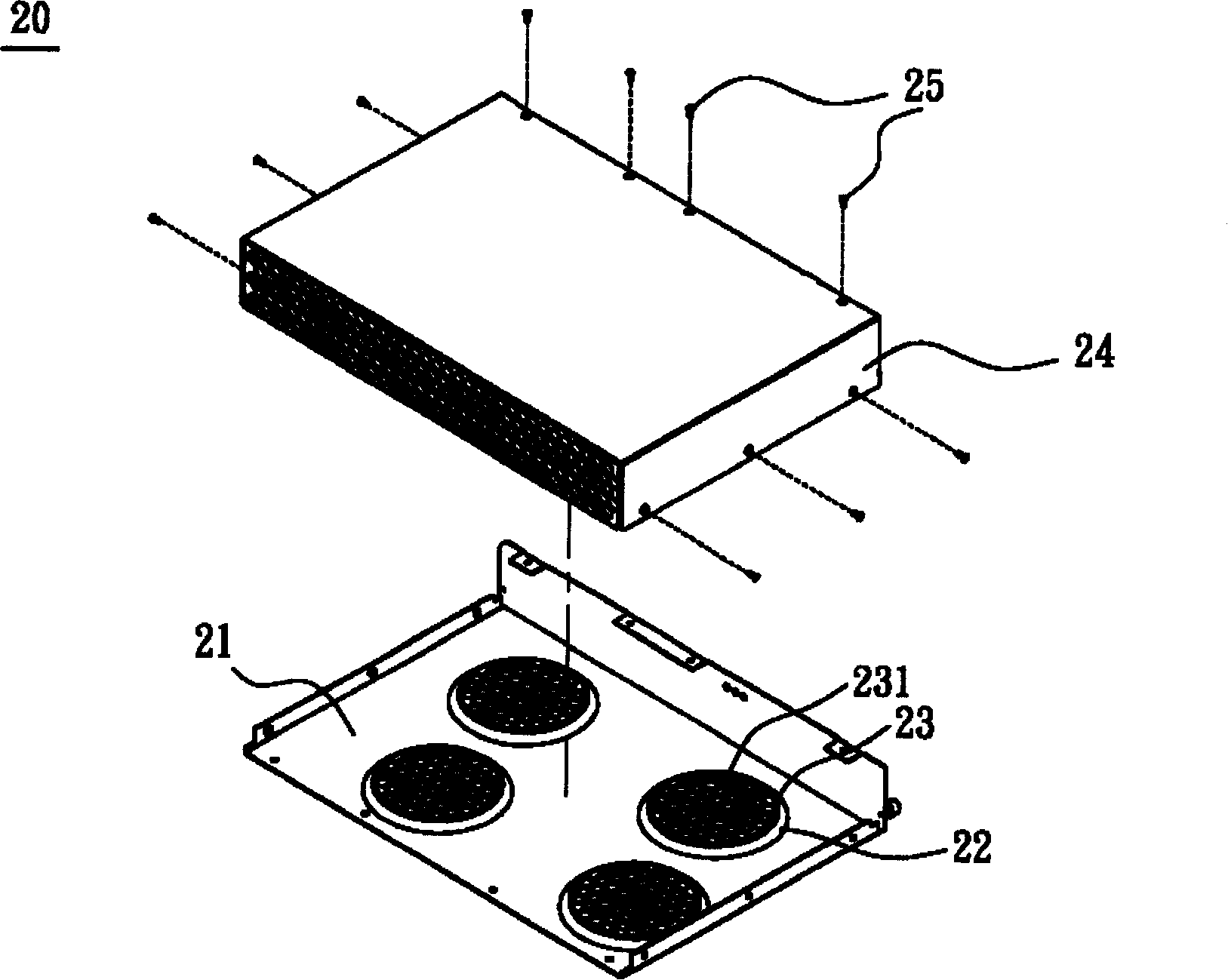

[0032] The heat dissipation module and its housing according to preferred embodiments of the present invention will be described below with reference to related drawings. First, please also refer to image 3 , Figure 4 and Figure 5 , to illustrate the housing of the heat dissipation module in the preferred embodiment of the present invention. image 3 It is a schematic diagram of a housing of a heat dissipation module in a preferred embodiment of the present invention, such as image 3 As shown, a housing 20 of a cooling module includes a first housing body 21 and a second housing body 24 . Figure 4 is a schematic diagram of the first shell body in a preferred embodiment of the present invention, and Figure 5 for along Figure 4 The schematic diagram of the cross-section of the guide part and the through-hole area made by the straight line C-C' in the middle. Note that, Figure 4 The first shell body 21 shown in, is connected with image 3 The direction in which th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap