Fuel cell with catalytic heater

A fuel cell and fuel cell stack technology, which is applied in the directions of fuel cells, fuel cell additives, electrochemical generators, etc., can solve the problems of reducing the conductivity of electrolyte composites, achieve fast and uniform operating temperature, and accelerate heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

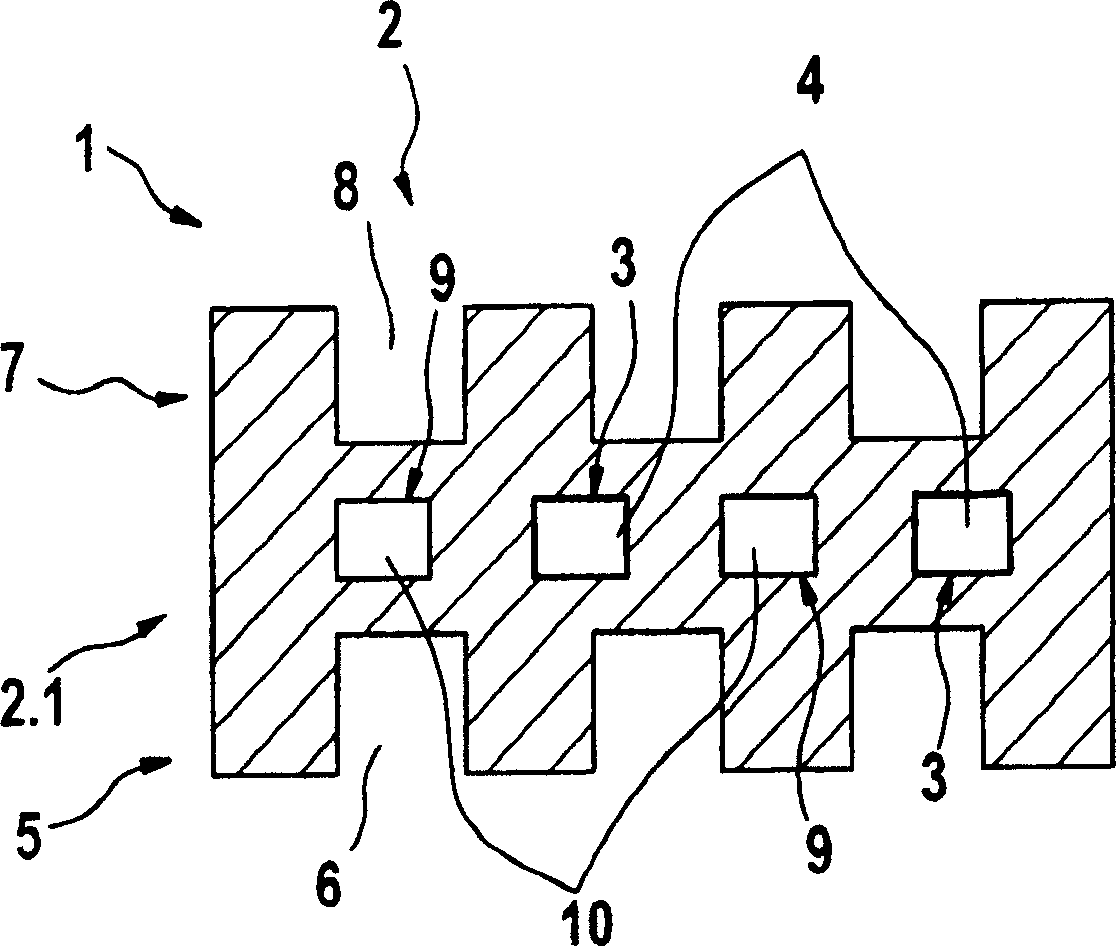

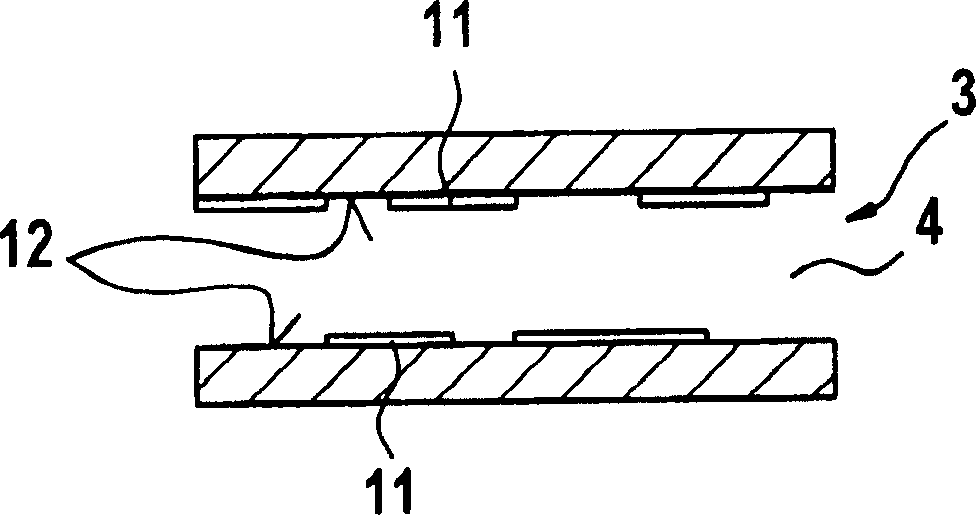

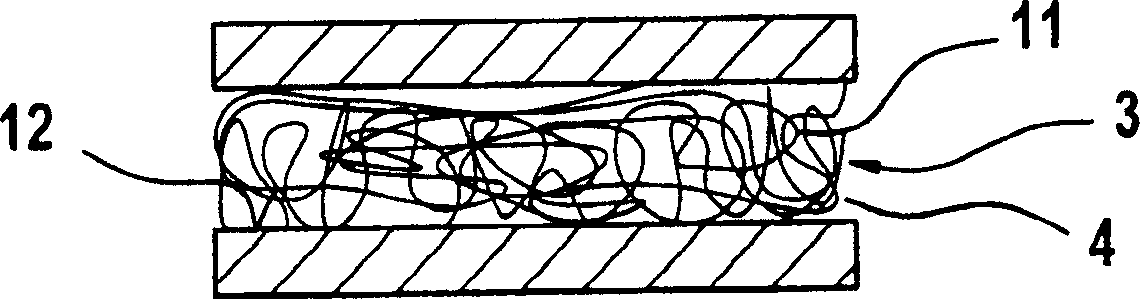

[0022] figure 1 A cross-sectional view of a bipolar plate 2 of a fuel cell 1 with heating channels 4 of a heater 3 based on the heat of catalytic reactions is shown. This configuration of the heating channel 4 is a preferred embodiment, but can of course differ from this embodiment. In particular, additional heating channels 4 can also be provided, for example on end plates (not shown).

[0023] The bipolar plate 2 shown here is therefore divided into, in addition to the main body 2.1 with the heating channels 4 , a region 5 adjacent to the main body, pointing downwards in the drawing, and another region opposite this in the drawing. The upper part 7 pointing upwards. The lower part 5 has fuel channels 6 formed therein as fuel-carrying component 5 . The upper part 7 has oxidant channels 8 formed therein as oxidant-carrying component 7 .

[0024] The exemplary embodiment of a bipolar plate 2 of a fuel cell 1 shown here is also equipped with cooling 9 , which is realized by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com