Aluminum alloy and smelting method thereof

A technology of aluminum alloy and tungsten alloy, applied in aluminum alloy and its smelting method and application field, to achieve the effect of improving electrical conductivity, reducing component loss, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

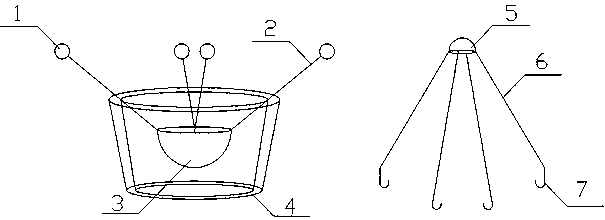

Image

Examples

Embodiment 1

[0030] Take a 100ml beaker and pour 25.5ml of absolute ethanol, dissolve 1.5g of graphene oxide in absolute ethanol and ultrasonically shake for 20min, add 2.6g of pure silicon powder and 6.9g of pure magnesium powder successively, stir evenly for 20min, then add 0.5g of glass powder and 0.5 g of ethyl cellulose was uniformly stirred for 10 minutes and then placed in an oven at 60° C. for 20 minutes to obtain the added slurry. Use coarse sand to roughen the surface of the tungsten alloy ball by high-speed shot peening for 15 minutes, put it into the slurry and roll it back and forth, so that all the slurry is attached to the surface of the tungsten alloy ball, and dry at 60°C for 10 minutes.

[0031] 750g of pure aluminum was smelted in a resistance furnace, the heating rate was 15°C / min, the melting temperature was 680°C, and the temperature was kept for 20min to obtain liquid aluminum. Then put the tungsten alloy ball covered with the slurry into the molten aluminum through ...

Embodiment 2

[0033]Take a 100ml beaker and pour 26ml of absolute ethanol, dissolve 2g of graphene oxide in absolute ethanol and ultrasonically shake for 10min, add 2.8g of pure silicon powder and 6g of pure magnesium powder successively, stir evenly for 10min, then add 0.6g of glass powder and 0.5g of ethyl alcohol Base cellulose, stir evenly for 5 minutes, put it in an oven at 60°C and keep it warm for 20 minutes to obtain the added slurry. Use coarse sand to roughen the surface of the tungsten alloy ball by high-speed shot peening for 10 minutes, put it into the slurry and roll it back and forth, so that all the slurry is attached to the surface of the tungsten alloy ball, and dry at 60°C for 10 minutes.

[0034] 750g of pure aluminum was smelted in a resistance furnace, the heating rate was 20°C / min, the melting temperature was 700°C, and the temperature was kept for 15min to obtain liquid aluminum. Then put the tungsten alloy ball covered with the slurry into the aluminum liquid throug...

Embodiment 3

[0036] Take a 100ml beaker and pour 26.5ml of absolute ethanol, dissolve 3g of graphene oxide in absolute ethanol and ultrasonically shake for 15min, add 2.5g of pure silicon powder and 7g of pure magnesium powder successively, stir evenly for 15min, then add 0.8g of glass powder and 0.5g of Ethyl cellulose was evenly stirred for 10 minutes and then placed in an oven at 60° C. for 20 minutes to obtain the added slurry. Use coarse sand to roughen the surface of the tungsten alloy ball by high-speed shot peening for 12 minutes, put it into the slurry and roll it back and forth, so that all the slurry is attached to the surface of the tungsten alloy ball, and dry at 60°C for 10 minutes.

[0037] 750g of pure aluminum was smelted in a resistance furnace, the heating rate was 25°C / min, the melting temperature was 720°C, and the temperature was kept for 10min to obtain liquid aluminum. Then put the tungsten alloy ball covered with slurry into the aluminum liquid through the tungsten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com