Small piezoelectric or electrostrictive linear motor

A linear motor and telescopic technology, applied in the field of China and Israel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

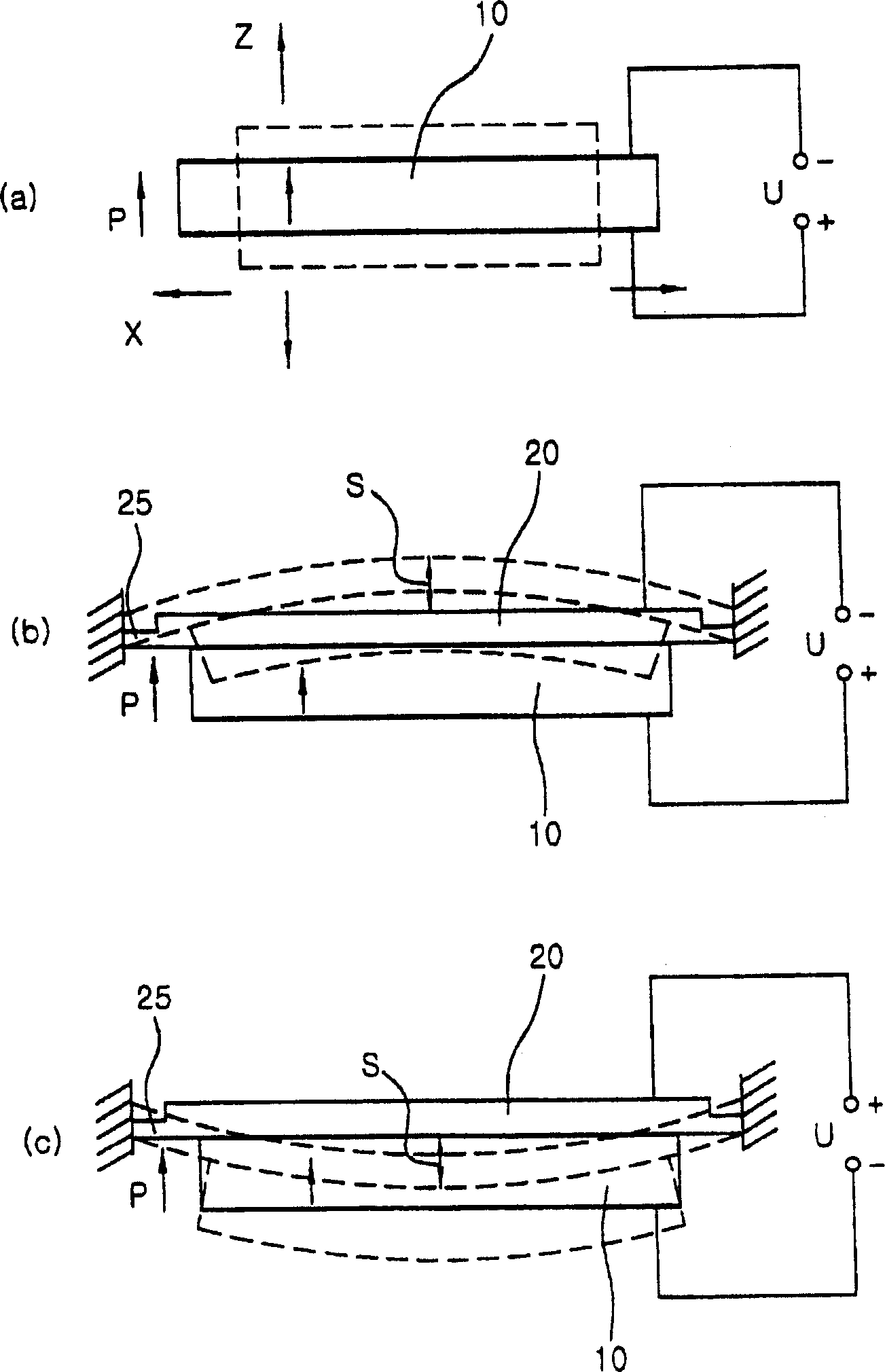

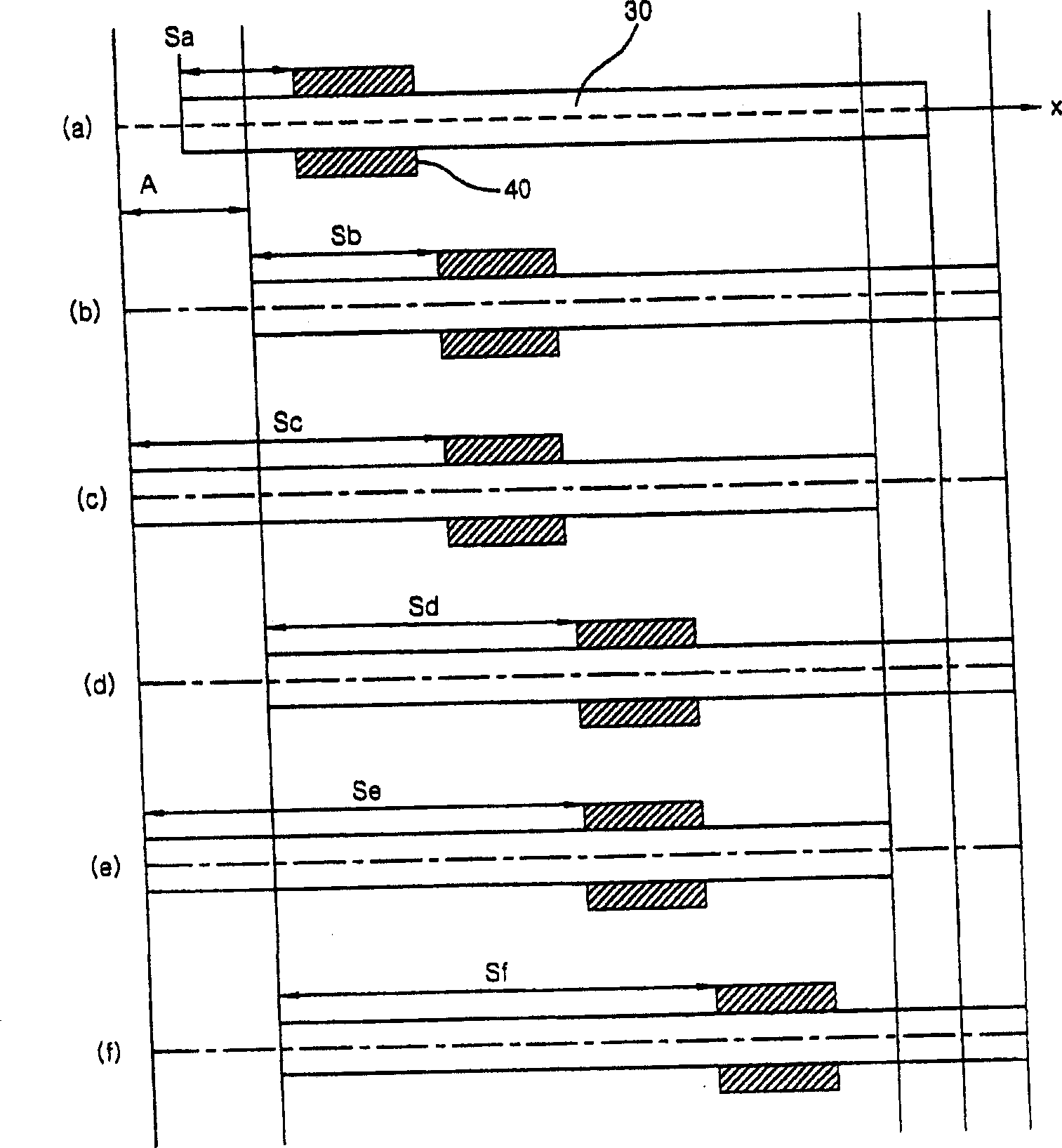

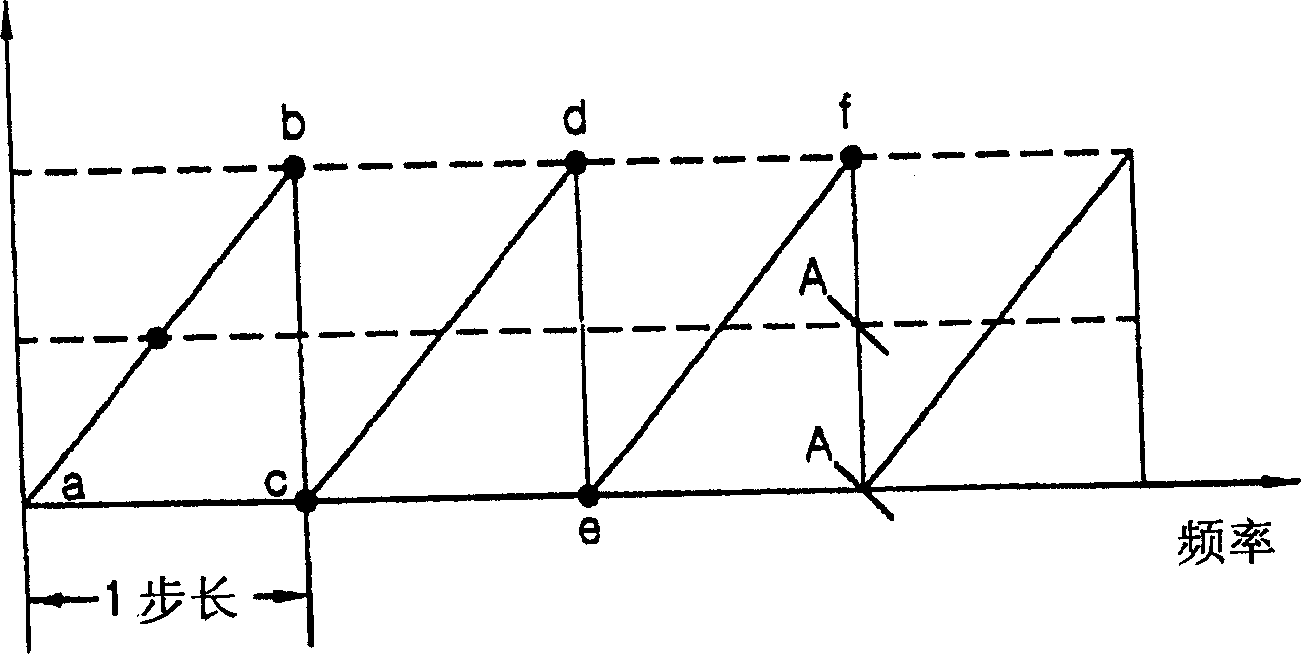

[0039] In order to achieve the above object, the present invention provides a basic structure including a piezoelectric or electrostrictive substrate 10 , a movable body 40 , a movable shaft 30 and an elastic body 20 . Also, in the present invention, various types of small piezoelectric / electrostrictive ultrasonic linear motors including linear motors having three structures that will be explained in the preferred embodiments are proposed based on the above basic configuration.

[0040] Figure 4 , Figure 5 and Figure 6 Three small piezoelectric / electrostrictive ultrasonic linear motors with the basic configuration described above are shown.

[0041] Figure 4 A first embodiment of the present invention including a piezoelectric or electrostrictive substrate 10 , an elastic body 20 and a movable body 40 is shown. The assembly of the piezoelectric or electrostrictive substrate 10 and the elastic body 20 forms a unimorph having a disk shape. The elastic body 20 is not lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com