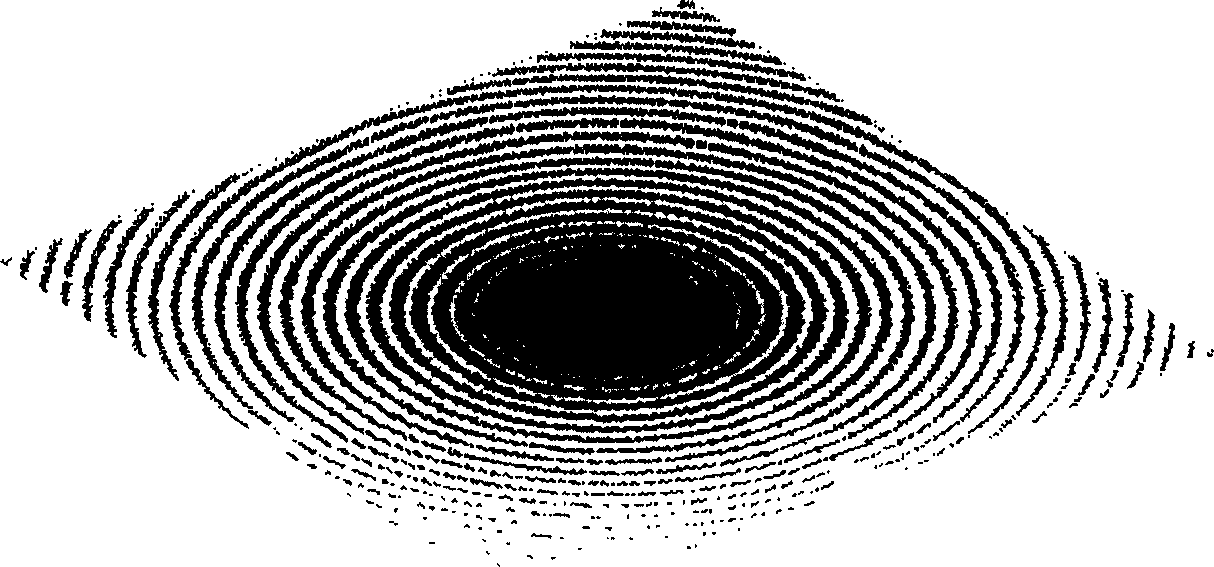

Diamond turning method and device for Archimedean spiral type Fresnel lens

An Archimedes spiral and Fresnel lens technology, applied in metal processing equipment, turning equipment, turning equipment, etc., can solve the problems of low precision, shortened tool life, long processing cycle, etc., to improve processing accuracy , to solve the fragile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

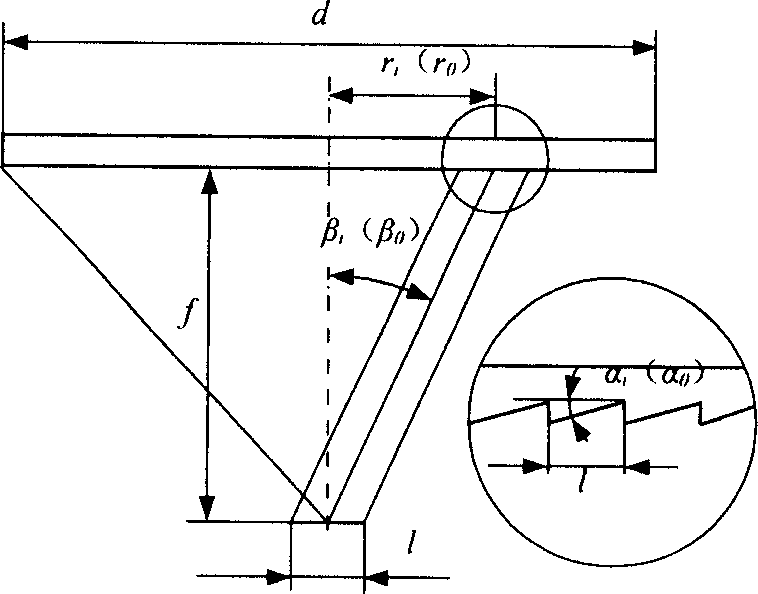

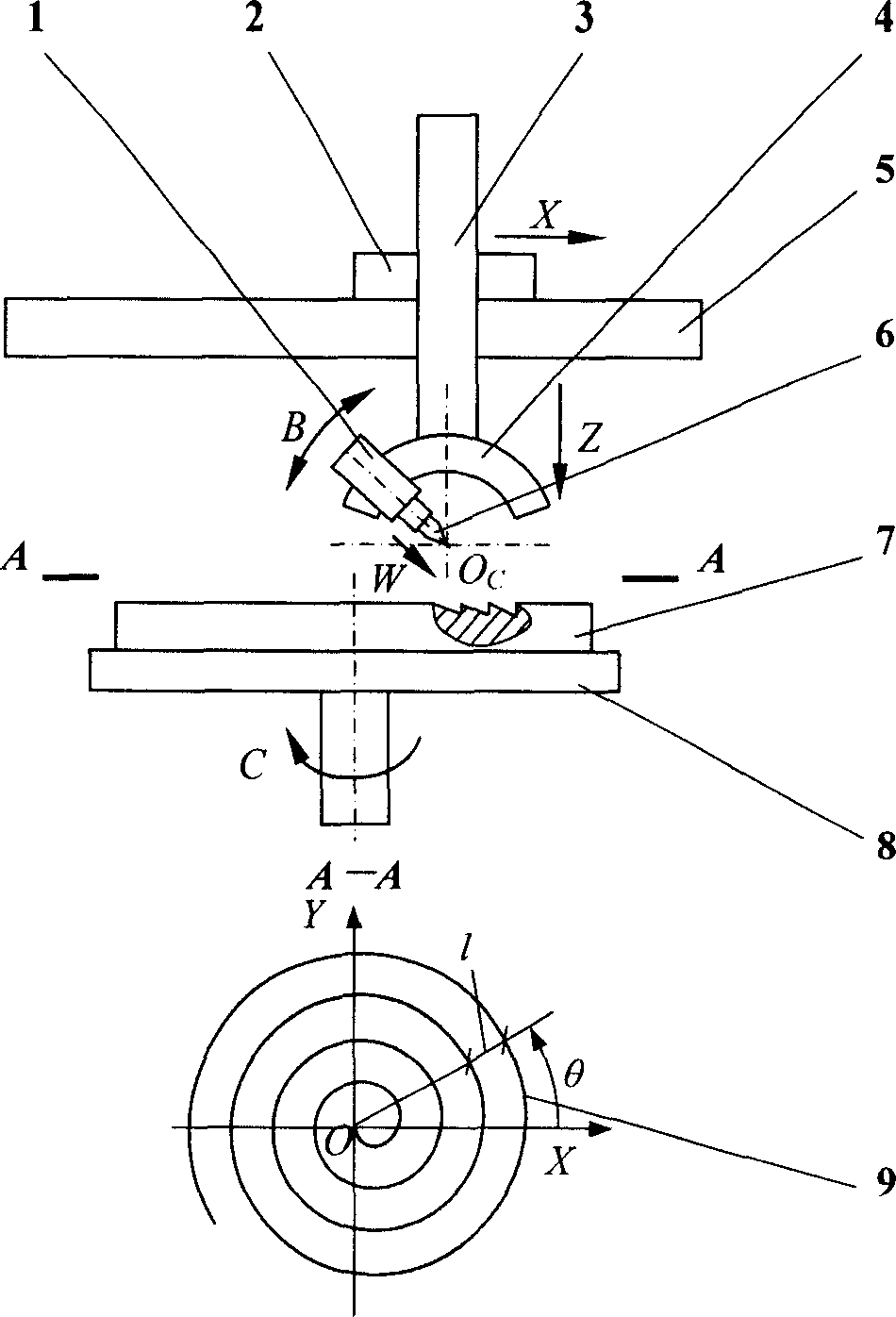

[0025] The present invention is an Archimedes spiral Fresnel lens proposed to solve the problems of shortened tool life, long processing cycle and low precision caused by intermittent machining of the conventional large-scale Fresnel lens diamond turning. Diamond turning processing method and device. exist image 3 In the schematic diagram of the diamond turning processing device for the Archimedes spiral Fresnel lens shown, the X-axis ram 2 moves along the guide rail fixed on the bed 5 to realize the X-axis movement, and the Z-axis ram 3 moves along the fixed The guide rail movement on the X-axis ram 2 realizes the Z-axis movement. The arc direct drive motor 4 is installed on the Z-axis ram 3 to realize the B-axis movement. The precision linear motor 1 is fixed on the moving part of the arc direct drive motor 4. On the sub, the diamond tool 6 is installed on the precision linear motor 1 and moves along the W axis output by the precision linear motor 1, the workpiece 7 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com