Pressure bearing forced circulation solar energy collecting flat roof

A technology of solar heat collection and forced circulation, which is applied in the field of pressure-bearing forced circulation solar heat collection flat roofs, which can solve the problems of short service life, loose integration of solar water heating devices and buildings, and high cost, so as to improve thermal efficiency and reduce heat conduction losses , Improve the effect of heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

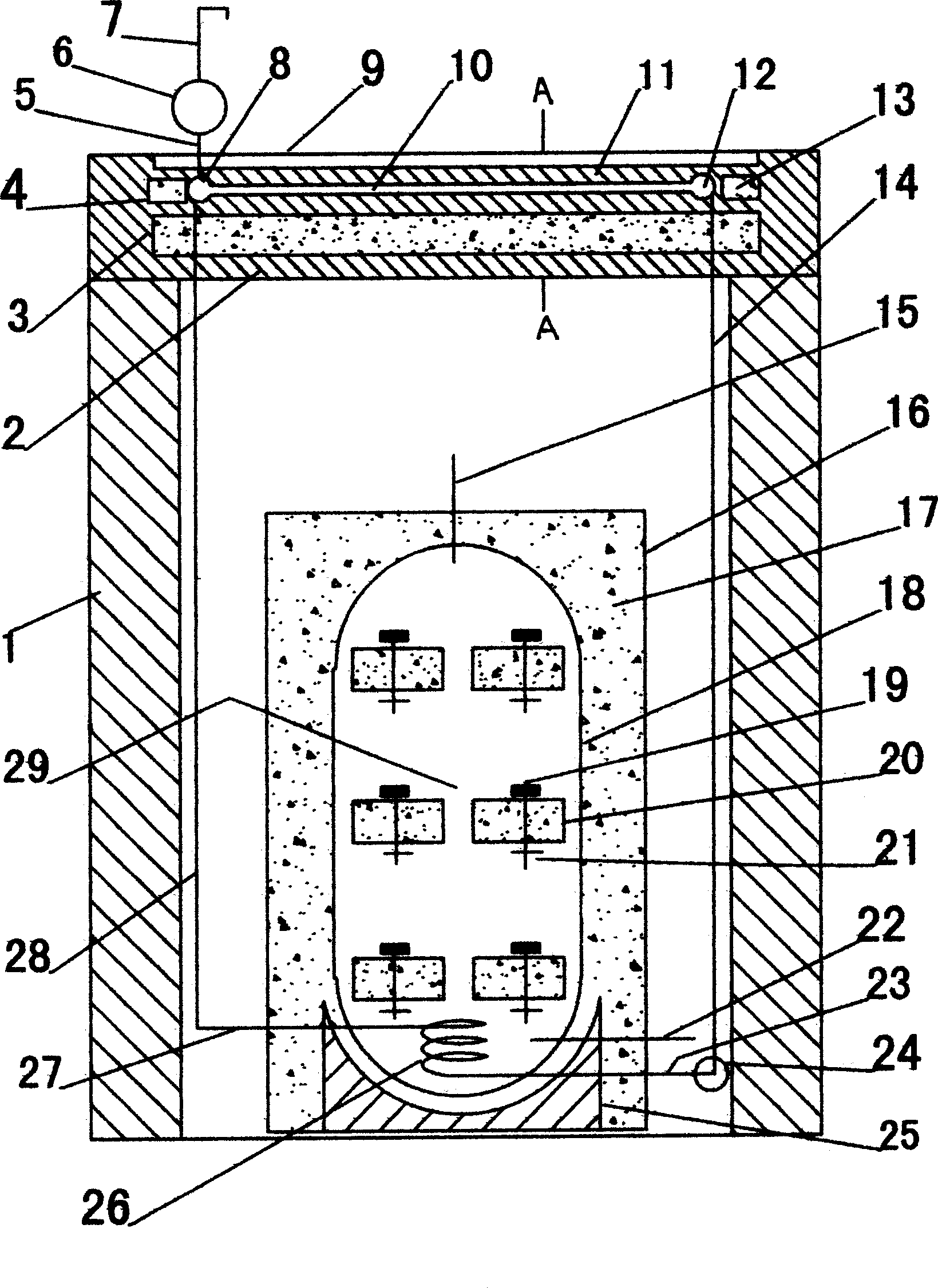

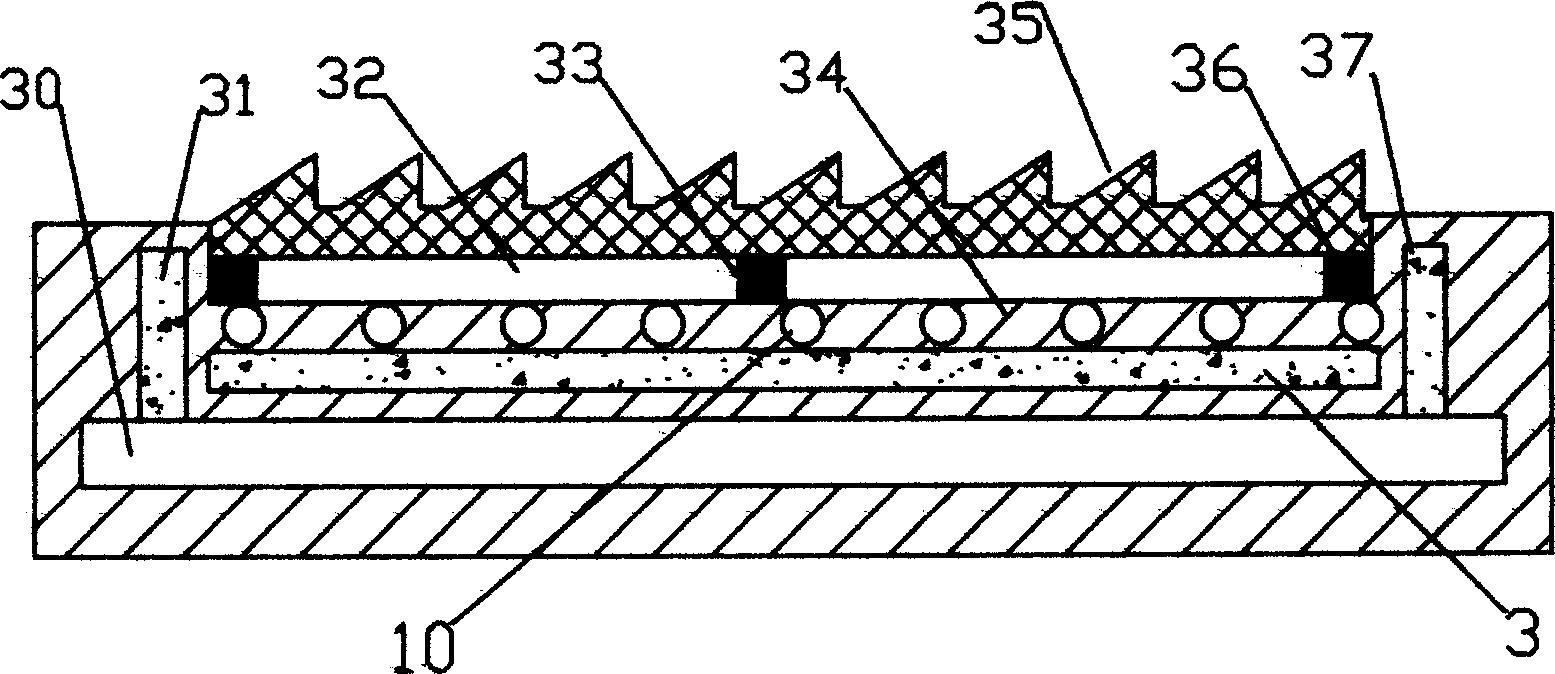

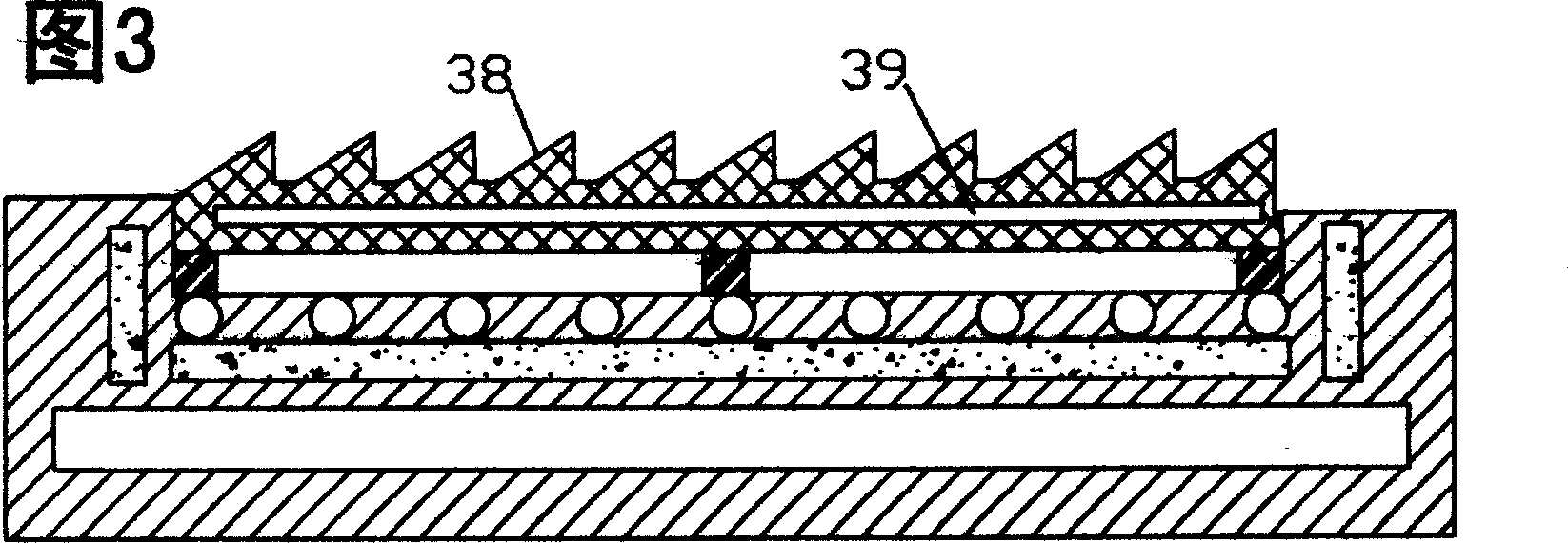

[0037] figure 1 , Figure 5 , Fig. 9 have jointly described a kind of pressurized forced double cycle solar heat collecting flat roof, the floor slab (2) is equipped with insulation layer (3), the cross-section of heat collecting pipe (10) and header pipe (8), (12) It can be circular, elliptical or polygonal, and they can be made of metal or non-metallic materials. When made of metal materials, the inner cavity can be coated with an anti-corrosion layer, or the outer layer can be made of metal, and the inner layer can be polymer The material is a metal-polymer composite tube, and the heat collecting tube is connected with the header to form a heat collecting core. The heat collecting core is installed on the heat insulating layer (3), and the heat collecting core is surrounded by heat insulating layers (4), (13), (41), (42), the heat collecting core and its insulation layer are buried in the middle of the concrete (11), the concrete surface is coated with a layer of long-life...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com