Test table for life saving boat lowering device

A lifeboat and test bench technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of high work intensity, untrue test status, and poor safety assurance, and achieve low investment, time-saving testing, and Easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

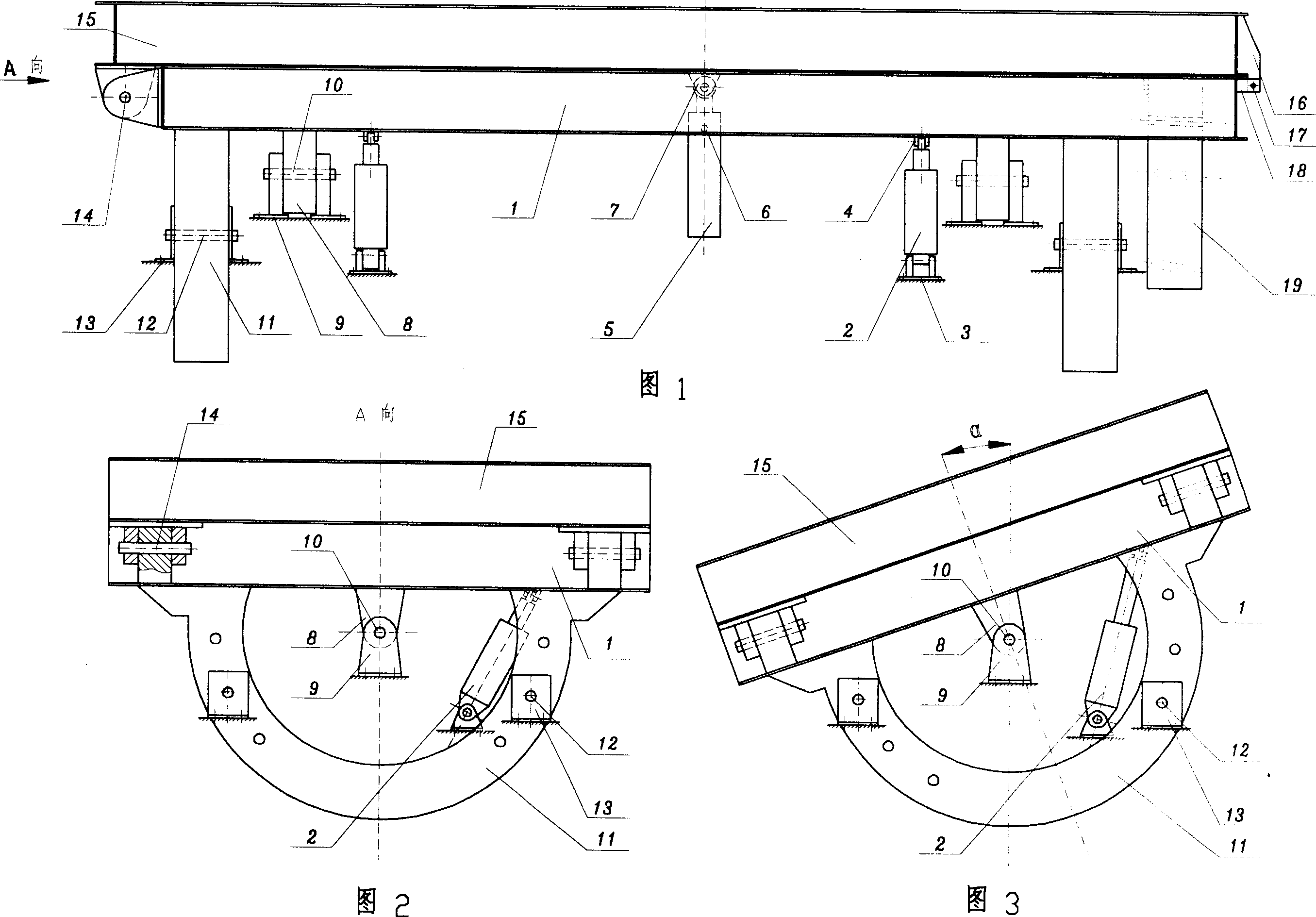

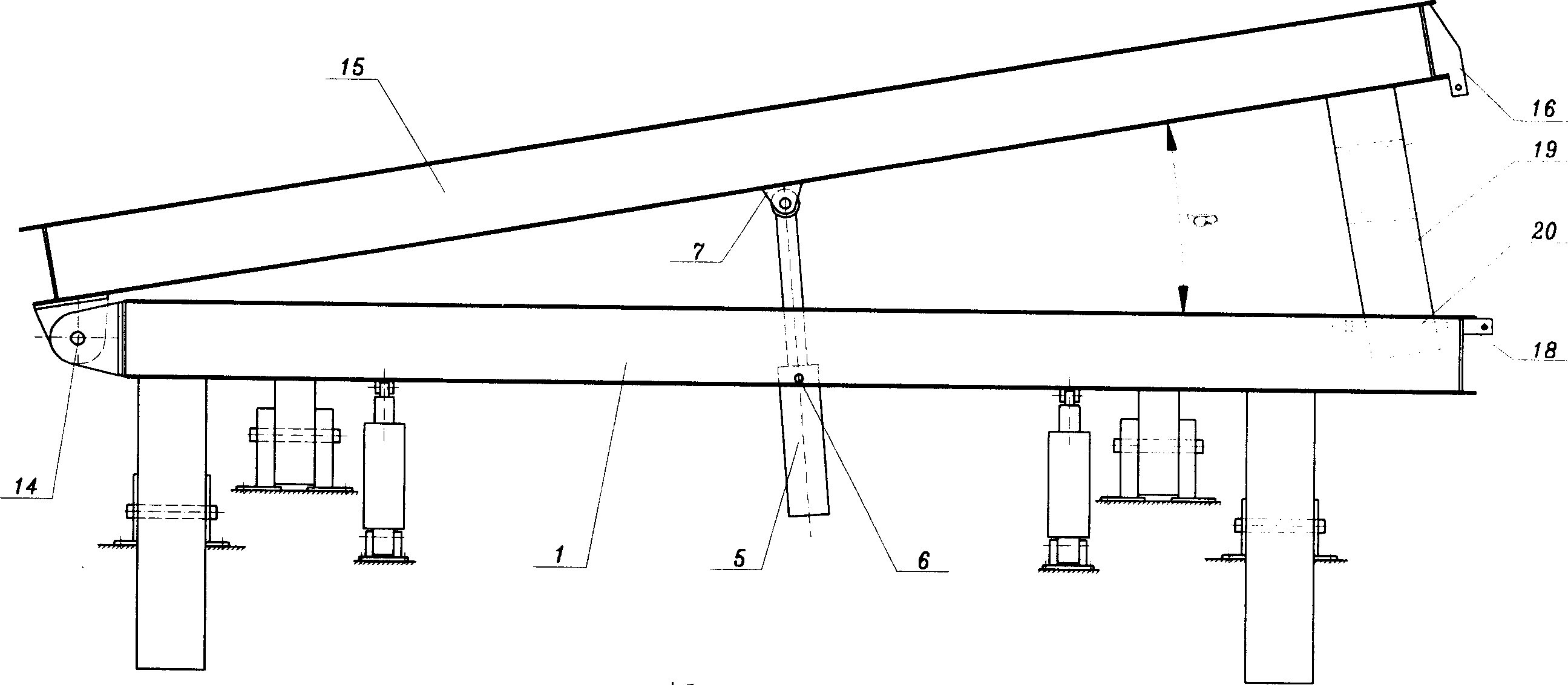

[0018] Description with reference to the accompanying drawings. In Fig. 1, the upper platform 15 and the lower platform 1 adopt a rectangular frame structure. The rear end of the upper platform 15 is connected to the rear end of the lower platform 1 through the trim shaft 14, and the trim oil cylinder 5 is respectively connected with the front swing shaft support 6 of the trim oil cylinder and the upper hinge seat 7 of the trim oil cylinder and is rotatable and telescopic. The front swing shaft support 6 of the oil cylinder is connected with the lower platform 1, the upper hinge seat 7 of the trim oil cylinder is welded on the upper platform 15, the trim oil cylinder 5 is a middle hinge type, the diameter of the piston rod is φ125 mm, the diameter of the piston is φ200 mm, and the stroke is 1300 mm . The upper end and the lower end of the heel cylinder 2 are respectively connected with the upper hinge seat 4 of the heel cylinder and the lower hinge seat 3 of the heel cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com