Cooling system for the cooling of heat-producing devices in an aircraft

A cooling system and equipment technology, applied in lighting and heating equipment, aircraft kitchens, aircraft parts, etc., can solve the problem of inflexible space distribution, and achieve the effect of flexible layout, reliable cooling system, and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

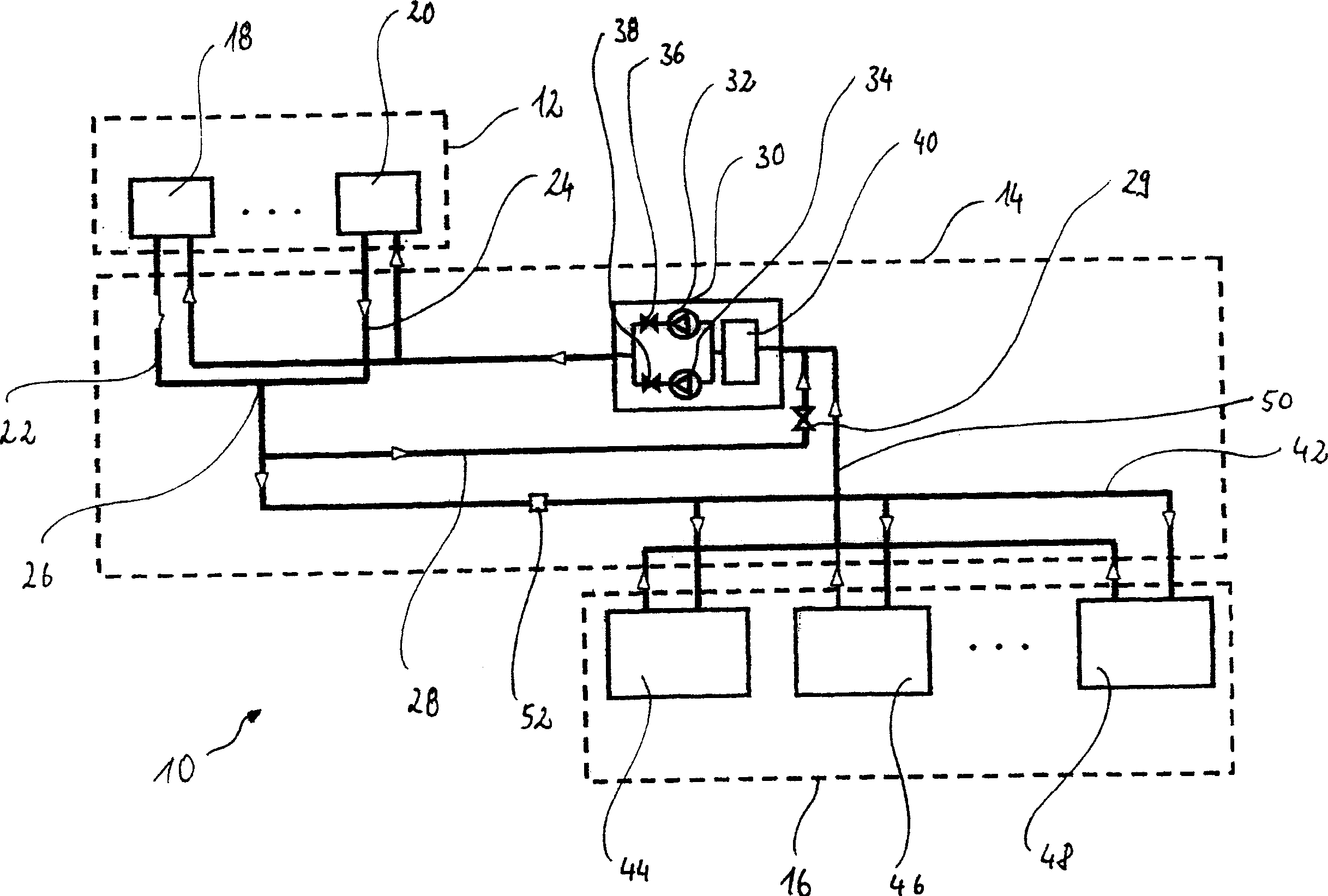

[0026] in the attached figure 1 , the cooling system according to the present invention is shown with reference numeral 10 . It includes refrigeration equipment 12 , a cold delivery system 14 , and an area 16 that consumes cold.

[0027] The refrigeration plant 12 has two coolers 18 and 20 in which the cold carrier medium is cooled by the cold evaporation process known in the field of thermodynamics and supplied to the cold transfer system 14 along two parallel lines 22 and 24 of a cooling circuit 25 . In cold transfer system 14 , two parallel lines 22 and 24 meet at point 26 . The cold carrier medium is supplied to the pump unit 30 via a supply line 28 provided with a specially controllable non-return valve 29 . The pump unit 30 has two pumps 32 and 34 which can be controlled in parallel with each other, for which pumps 32 and 34 are provided with independently controllable non-return valves 36 and 38 . The intermediate storage unit 40 of the cold carrier medium is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com