Person-carried transporting system and rope for an elevator

A technology for conveying systems and elevators, applied in the field of cables, can solve problems such as limiting durability, and achieve the effect of preventing friction and contact and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

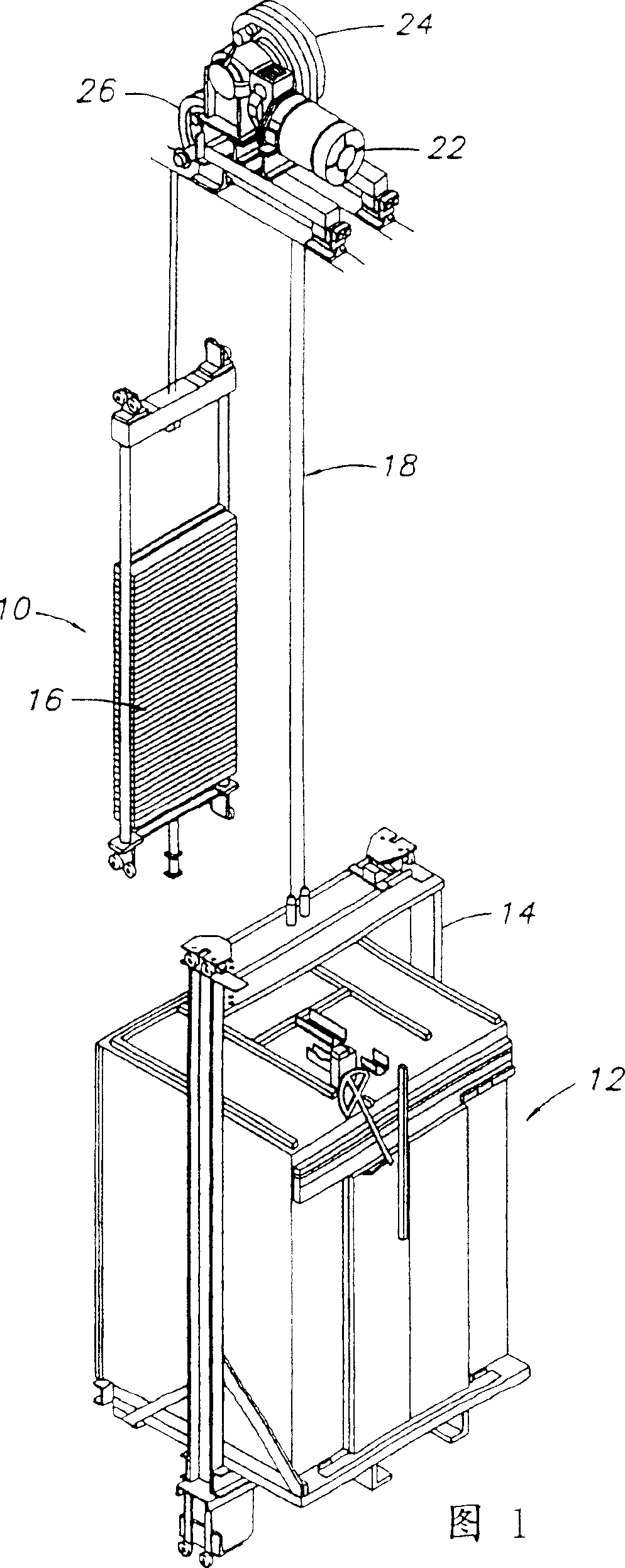

[0020] Figure 1 shows an elevator system 10 with the hoistway and hoisting components, such as guide rails, removed for clarity. Elevator system 10 includes a car 12 on a car frame 14 , a counterweight 16 , a pair of hoist ropes 18 connecting the car frame 14 to the counterweight 16 , a drive motor 22 , and a traction sheave 26 . Although only two cables are shown for illustration, those skilled in the art will appreciate that a greater number of cables may be used, the exact number of cables depending on the particular application.

[0021] Drive to rotate the traction sheave 24 is provided by a drive motor 22 . Friction between the pulley 24 and the hoisting rope 18 creates traction that pulls the hoisting rope 18, thereby causing the car 12 or counterweight 16 to move up and down in the hoistway. The traction between the hoist rope 18 and the pulley 24 can also provide a reaction force to keep the car frame 14 stationary when the pulley 24 is not rotating, such as when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com