Tunnel overhead arch mould plate trolley possessing floating type traffic under carriage

A formwork trolley and underframe technology, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as high manufacturing costs, affecting the quality of concrete pouring, complex structures, etc., and achieve shortened construction periods, simple structures, and safe and reliable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

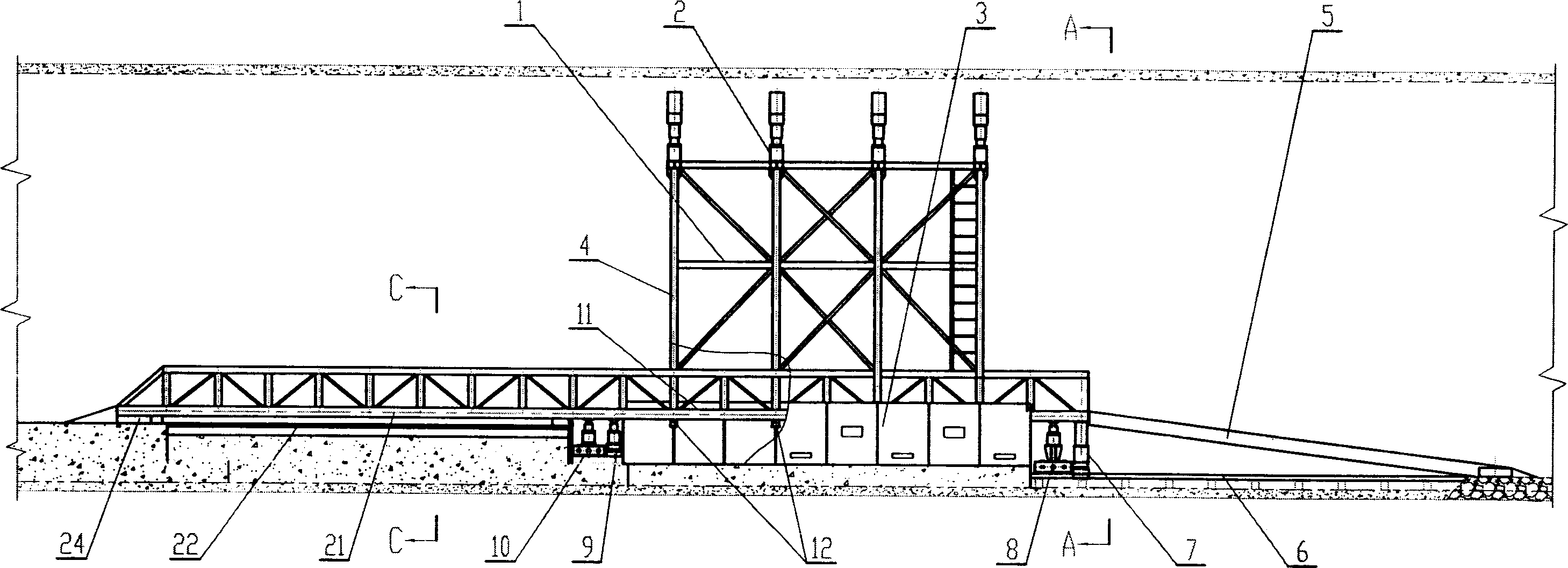

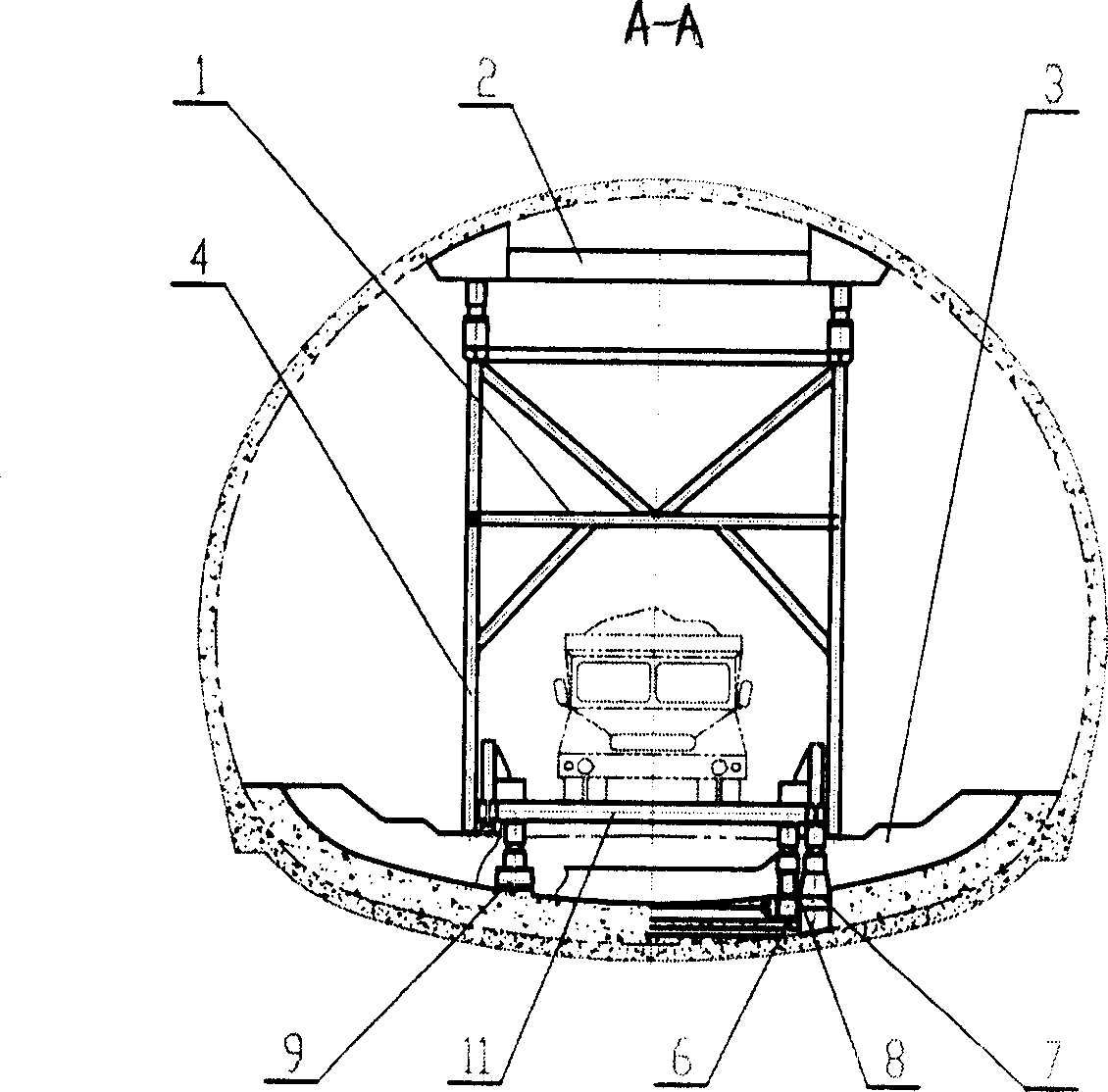

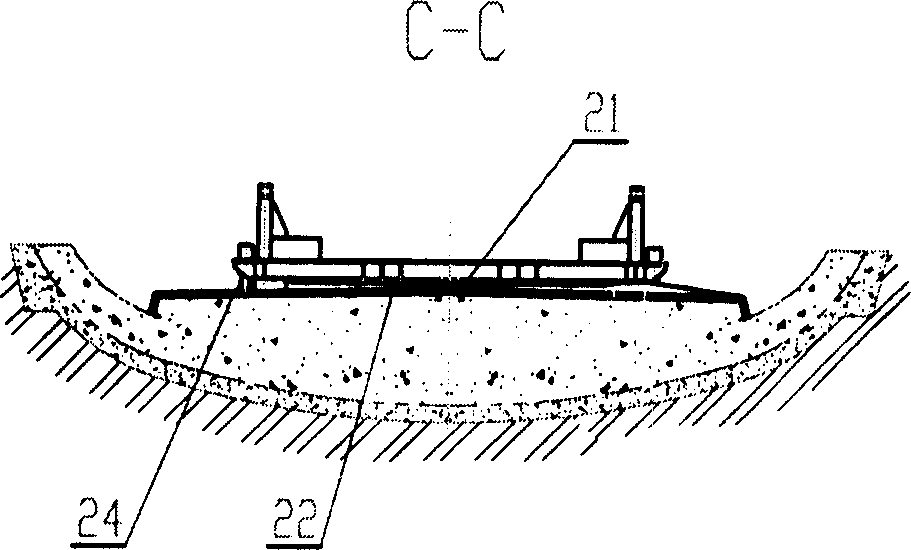

[0023] see Figure 1-3 , the composition of the tunnel inverted arch formwork trolley of the present invention comprises an anti-floating platform 2, a front traveling wheel 8, a rear traveling wheel 10, a lifting type front support seat 7, a rear support seat 9, and an empty stomach with a column 4 and a driving chassis 11. Type trolley frame 1 and the inverted arch formwork 3 arranged under the undercarriage 11, the front support base 7, the rear support base 9, the front travel wheels 8, and the rear travel wheels 10 are all installed at the bottom of the trolley frame 1. The anti-floating platform 2 is installed on the top of the trolley frame 1. The front traveling wheel 8 and the rear traveling wheel 10 are lift-type traveling wheels. The top of the arch formwork 3. Among the figure, 5 is the trestle bridge that enters trolley for slag truck, and 6 is track, all can continue to use prior art to arrange.

[0024] see Figure 4 The floating mechanism can be composed of ...

Embodiment 2

[0029] see Figure 7 -8, considering the situation that steel bars may need to be laid before the inverted arch pouring, in order to ensure the smooth forward movement of the trolley, an extension 25 can be set at the front end of the underframe of the trolley frame, and the front walking wheels 8 Mounted on the front end of the extension. Utilize this extended section to cross the next inverted arch pouring station of laying steel bar, make the front walking wheel 8 walk on the tunnel bottom surface before the next inverted arch pouring station. When walking, the front support seat 7 is upwardly folded and strides over the laid steel bar, so that the smooth forward movement of the trolley can be realized. Figure 6 is the track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com