Compressed natural gas injector

A technology of compressed natural gas and injectors, which is applied in the direction of machines/engines, oil supply devices, internal combustion piston engines, etc. It can solve the problems of injectors such as unstable operation, long response time, and ejector rod breakage, and achieve good sealing and responsiveness. The effect of short time and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

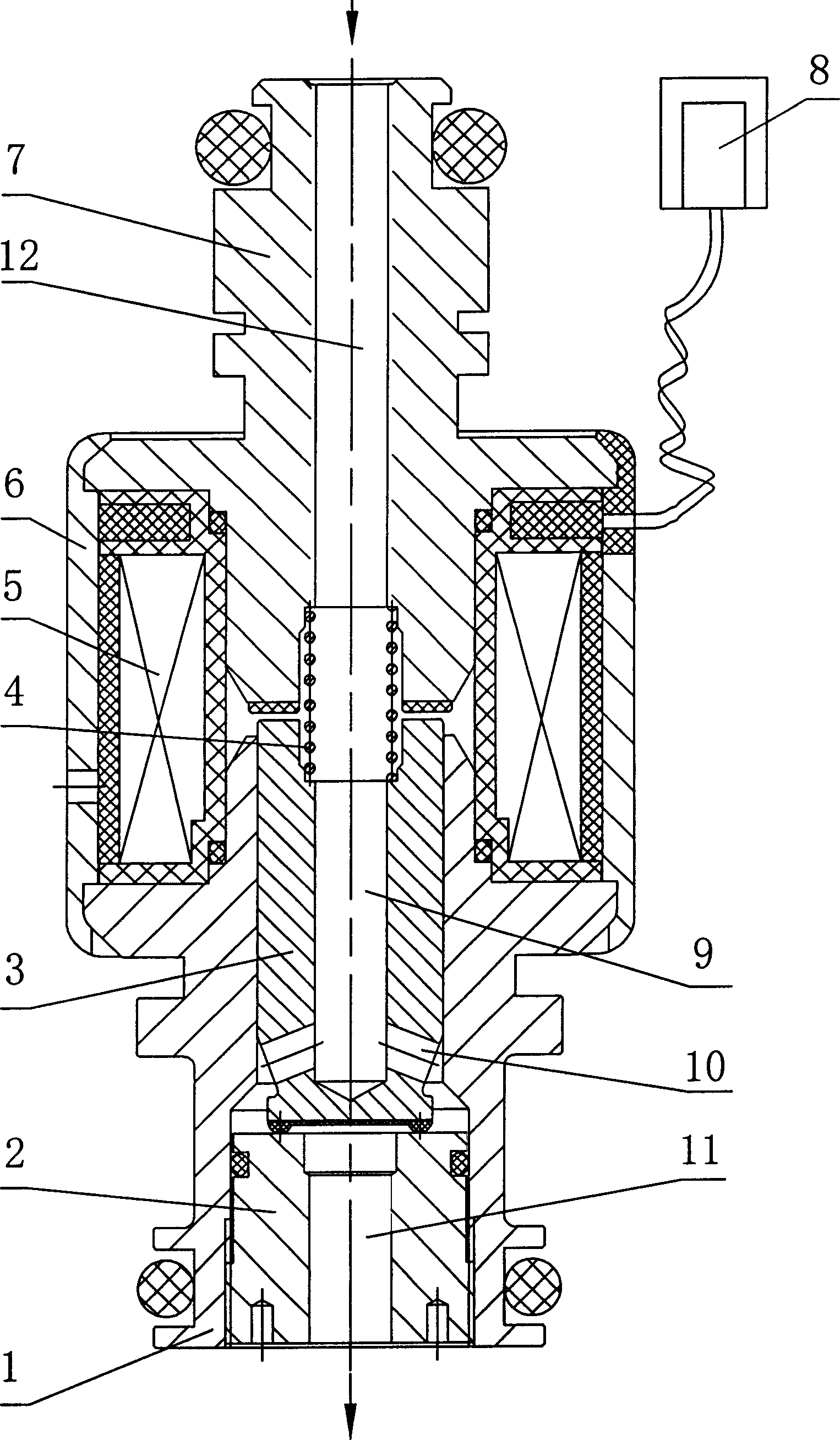

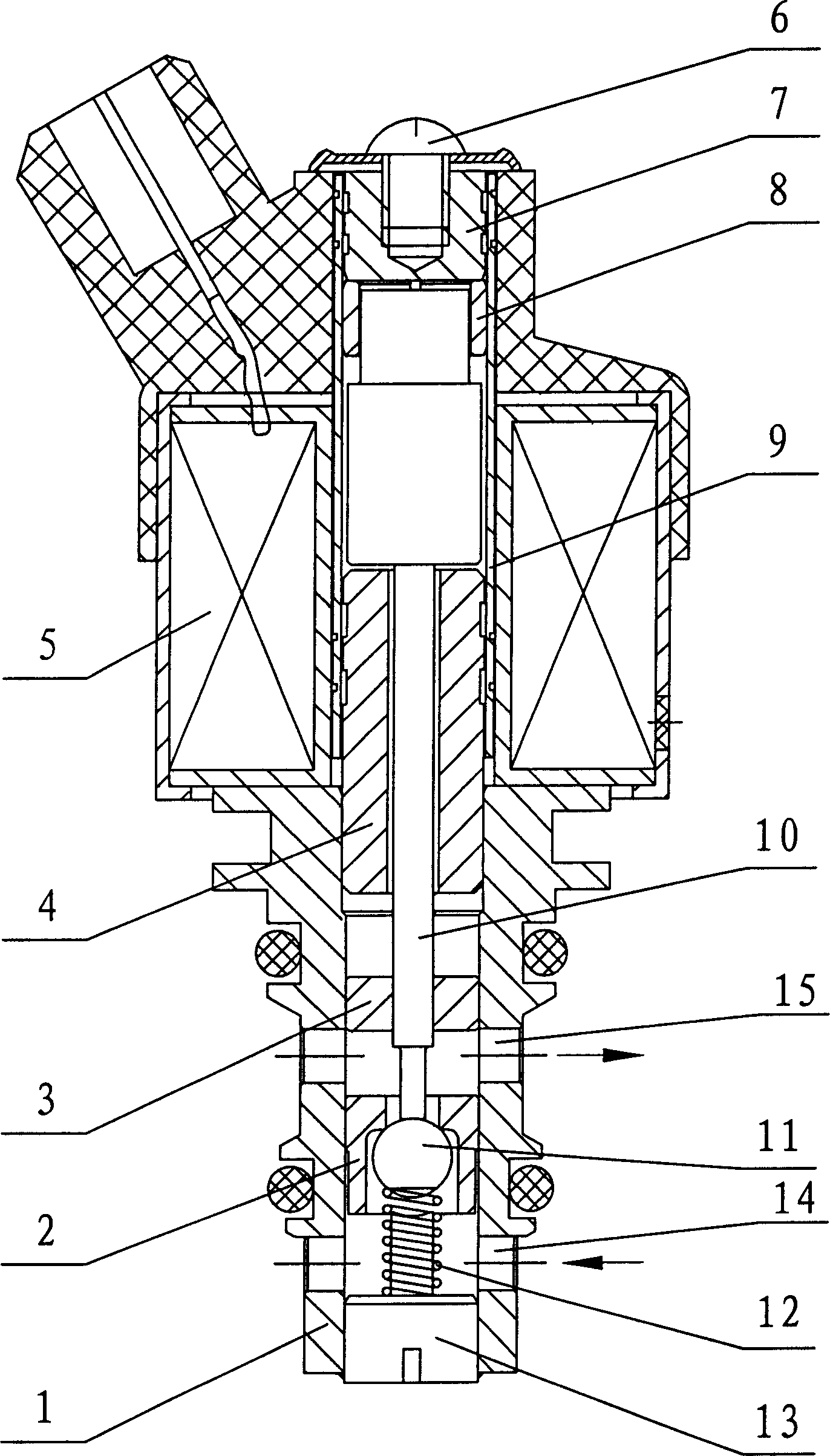

[0015] like figure 1 As shown, a compressed natural gas injector of the present invention is characterized in that it includes: an injector housing 1, a valve seat 2, an armature 3, a spring 4, a coil 5, a coil housing 6, a stop iron 7 and an electrical plug 8; The injector casing 1 and the iron stopper 7 are inserted into the hole of the coil 5, the coil casing 6 is set outside the coil 5, and the ends of the coil casing 6 are closed at both ends so that the coil casing 6, the coil 5, the iron stopper 7 and the injector casing The body 1 is connected as a whole; the valve seat 2, the armature 3 and the spring 4 are sequentially arranged in the inner hole of the injector housing 1 from bottom to top, the valve seat 2 and the injector housing 1 are screwed together, and the spring 4 tops The upper end of the armature 3; the retainer 7 is provided with an axial through hole 12, the upper end of the armature 3 is provided with an axial blind hole 9, the lower end of the armature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com