Double system car coupler of railway vehicle

A railway vehicle, dual-system technology, applied in railway car body parts, railway couplings, transportation and packaging, etc., to achieve the effects of simplified process, improved service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

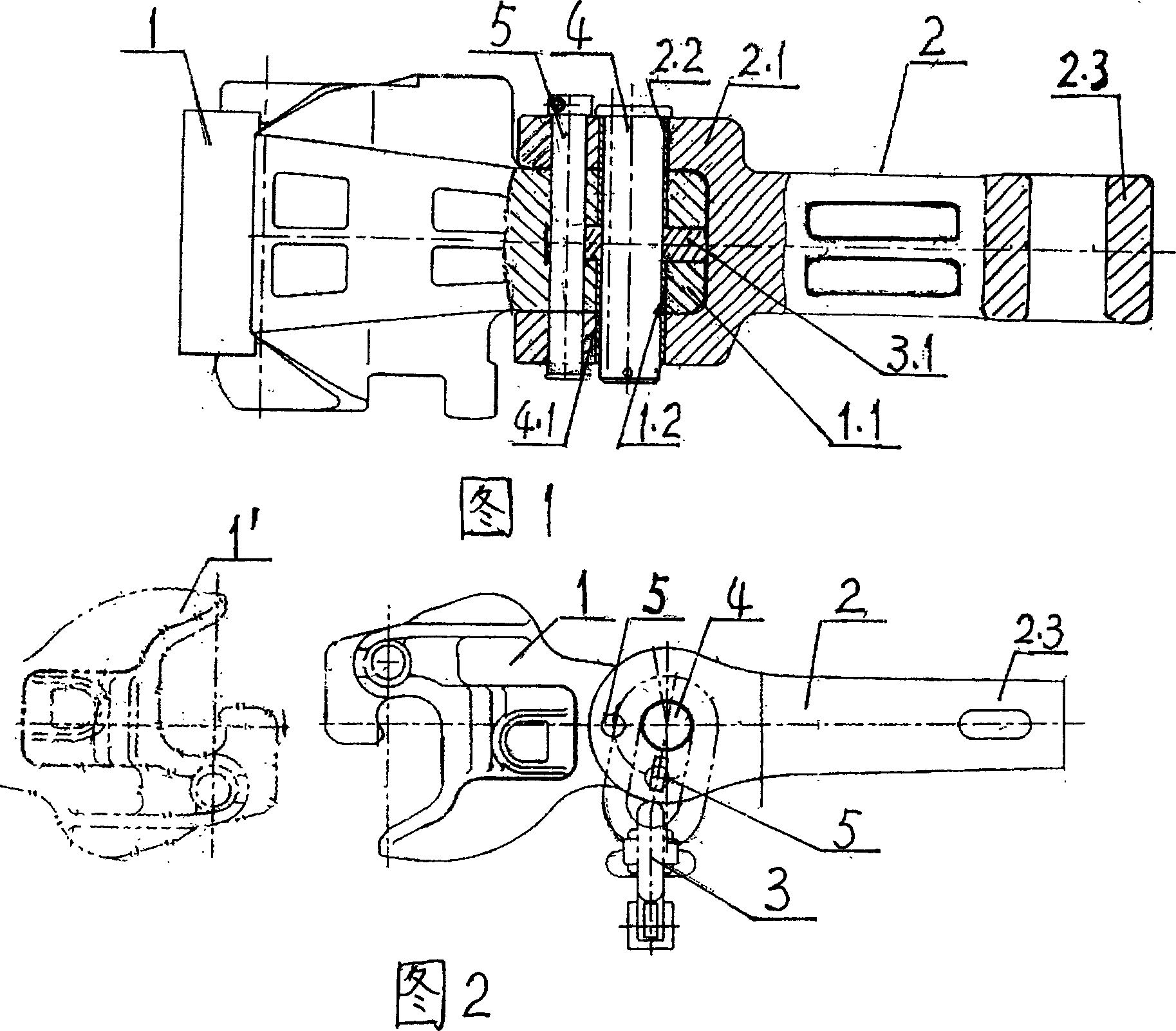

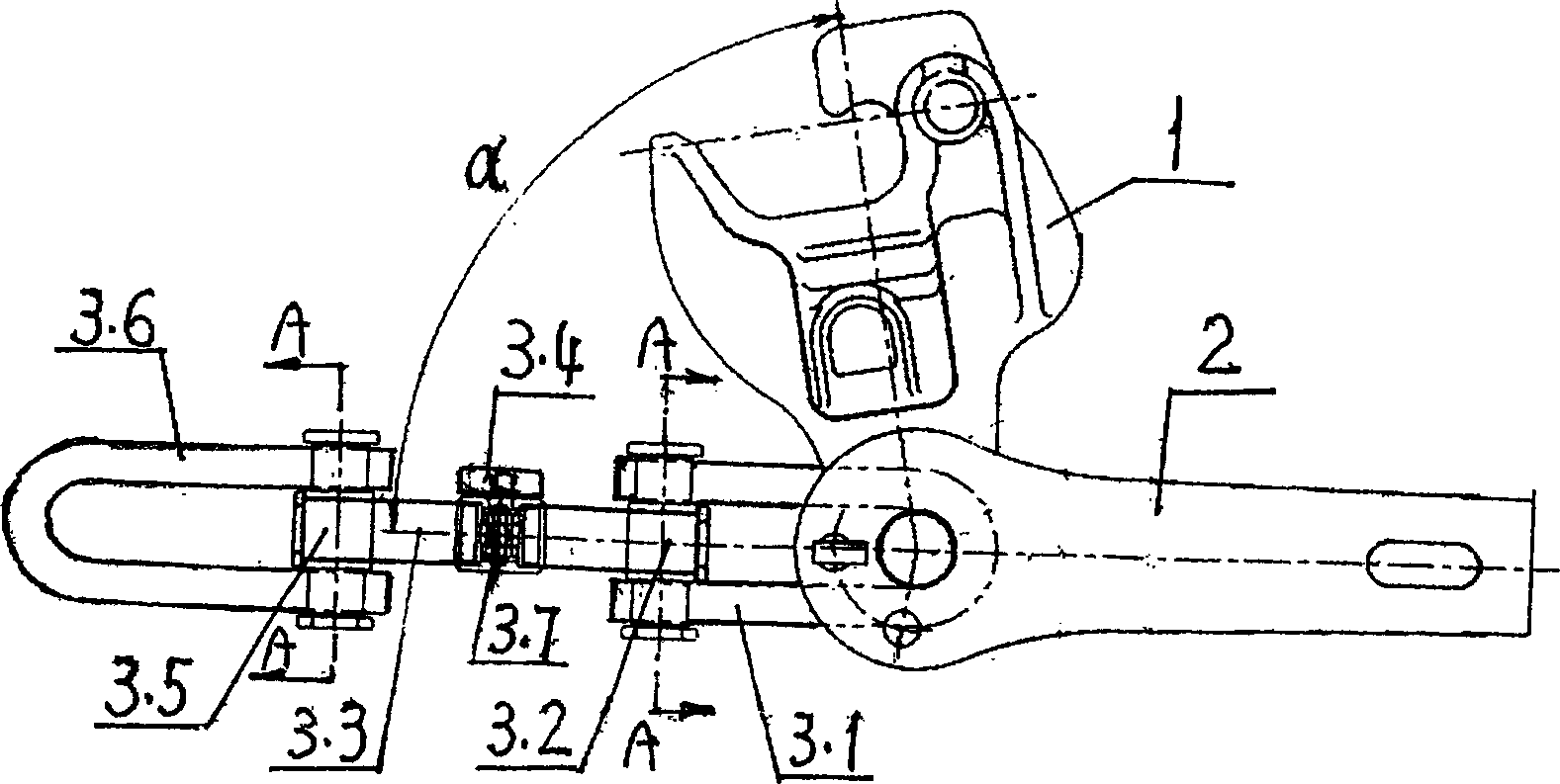

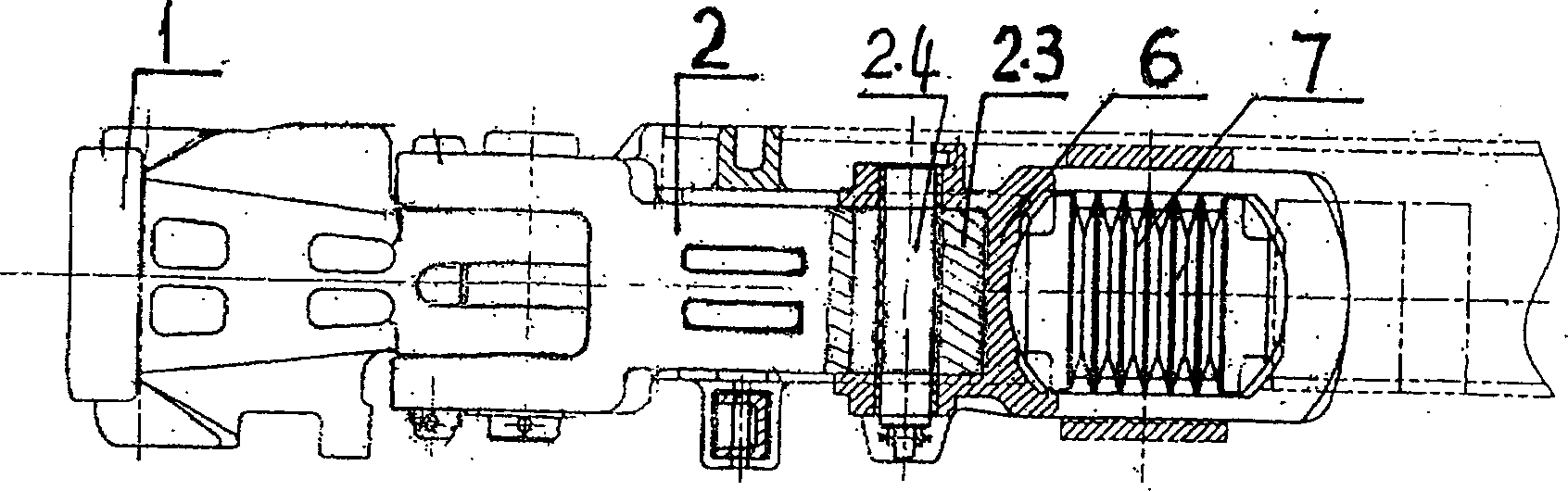

[0026] See Fig. 1, Fig. 2, the coupler of double system of railway vehicle of present embodiment is made of the bushing 4.1 of articulated coupler head 1, coupler body 2, chain coupler 3, connecting pin 4 and outer sheath, locating pin 5 etc. The U-shaped 1.1 tail end of the joint hook head 1 is inserted into the U-shaped 2.1 inner side of the front end of the hook body, and the U-shaped chain ring 3.1 of the chain coupler 3 is inserted into the U-shaped 1.1 inner side of the tail end; Movable joints. The tail-end U-shaped 1.1 and the front-end U-shaped 2.1 are respectively provided with connecting pin holes 1.2 and 2.2 for matching with the connecting pin 4 .

[0027] See Fig. 2, in the movable joint, when the joint head 1 rotates in the longitudinal traction direction of the vehicle, it is in the hanging working position, fixed with the positioning pin 5, and then moves along the traction direction to automatically dock with the automatic coupler 1' of the docked vehicle. N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com