Method of obtaining natural aluminum color for aluminum alloy anode after oxidation

An anodizing and aluminum alloy technology, applied in the direction of anodizing, can solve problems such as difficulty in meeting the above requirements, and achieve the effects of good extrusion performance, uniform distribution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

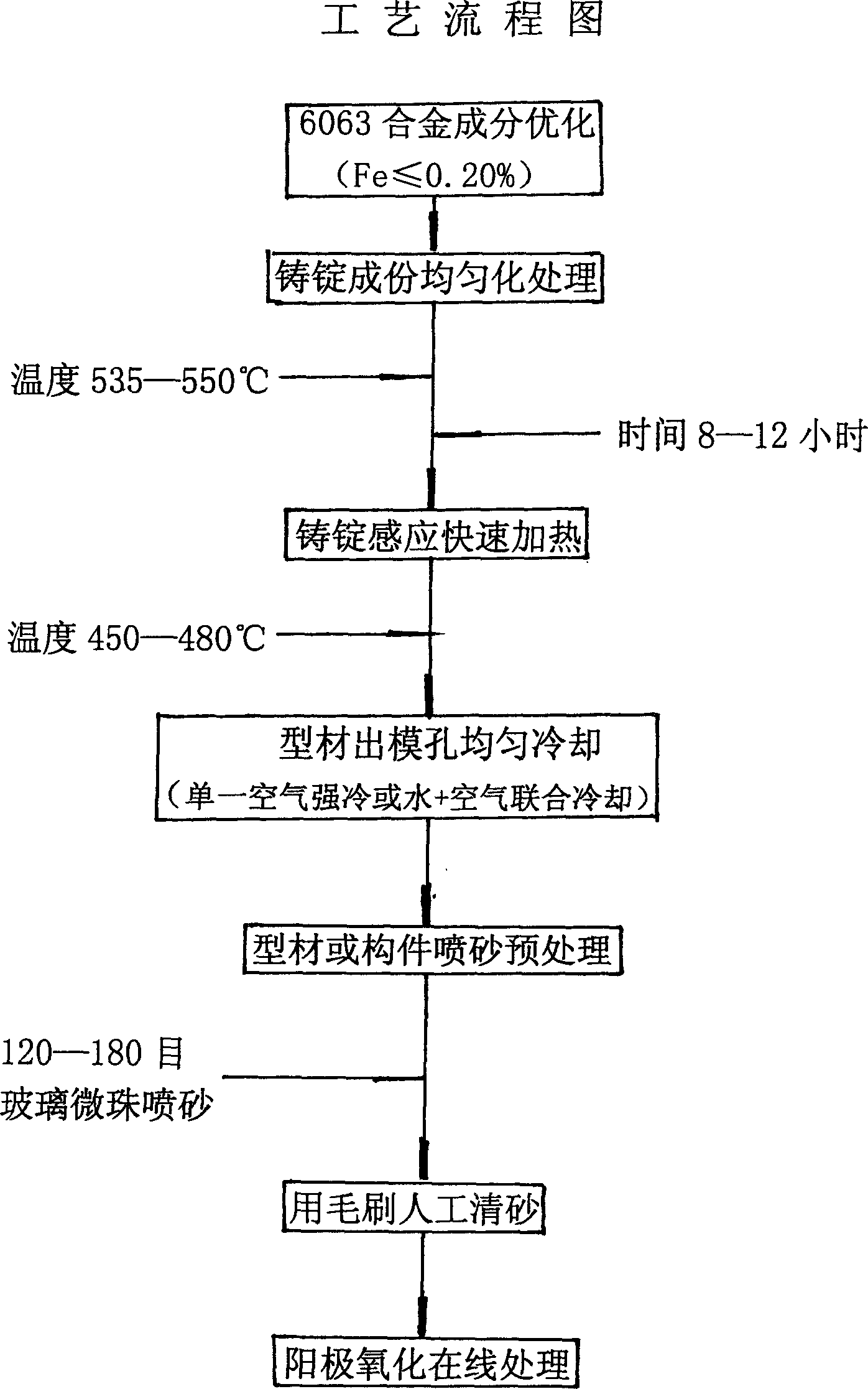

[0019] In order to further understand the characteristics and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows in conjunction with the accompanying drawings, please refer to figure 1 .

[0020] Such as figure 1 Shown: The method of obtaining natural aluminum color after anodizing aluminum alloy is as follows:

[0021] ①, 6063 alloy ingot composition optimization: Considering the influence of chemical composition on material uniformity, surface smoothness and brightness, it is necessary to achieve a fine and uniform microscopic crystal structure to reflect the chemical properties of the optimized metallurgical quality of the 6063 alloy. The composition range, the most important of which is the content of iron in the raw material aluminum, and its chemical element composition is:

[0022] Fe≤0.20%, Si=0.33-0.5%, Mg≤0.6%, Mn≤0.1%,

[0023] Cu=0.05-0.25%, Ti≤0.05, Zn≤0.05%;

[0024] ②. Full homogenizati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap