Underground liquid level monitoring system and its method

A liquid level monitoring and liquid level technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the problems of insensitive monitoring of well kick and lost circulation accidents, slow change of mud filling level, and poor response Long time and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

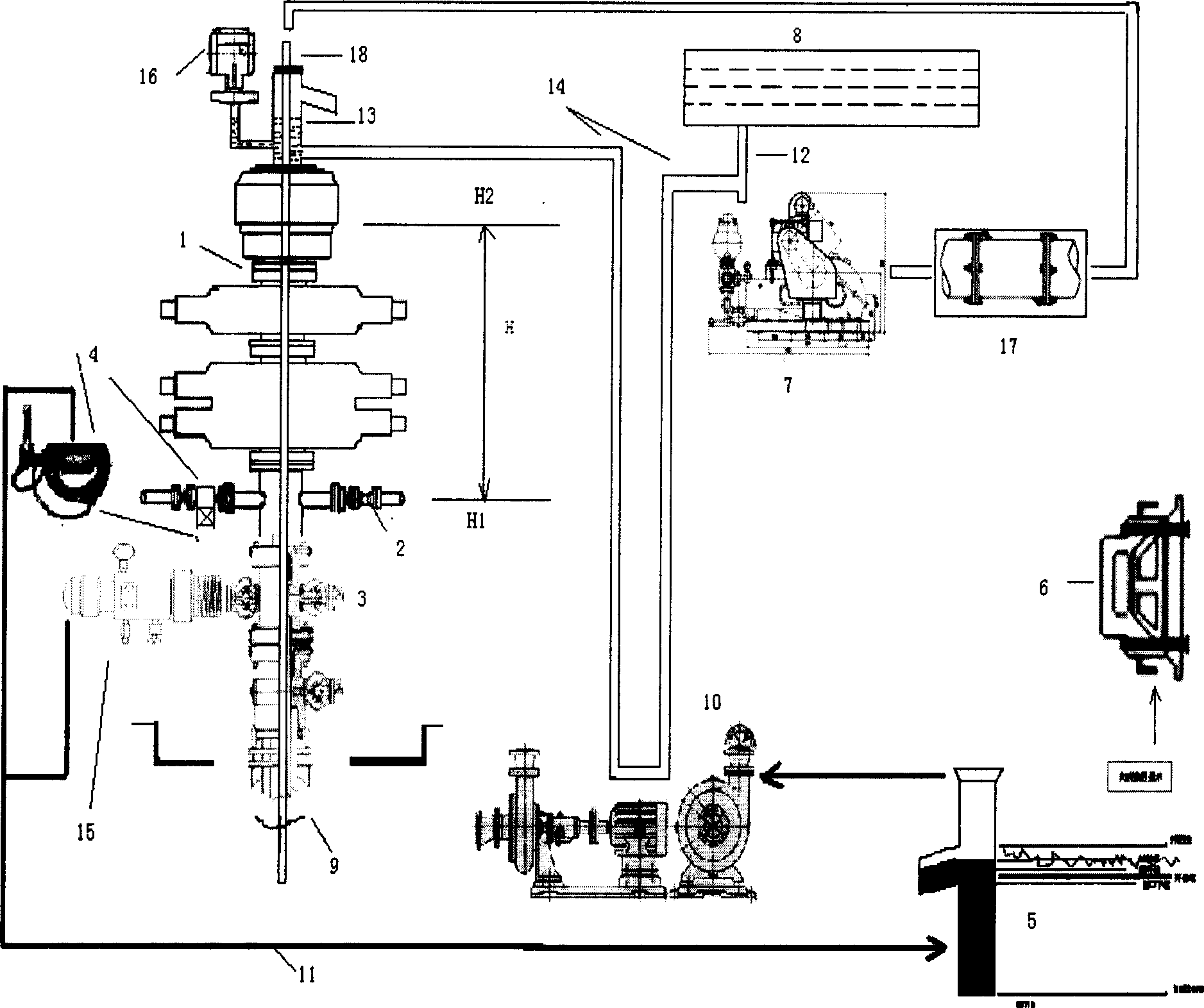

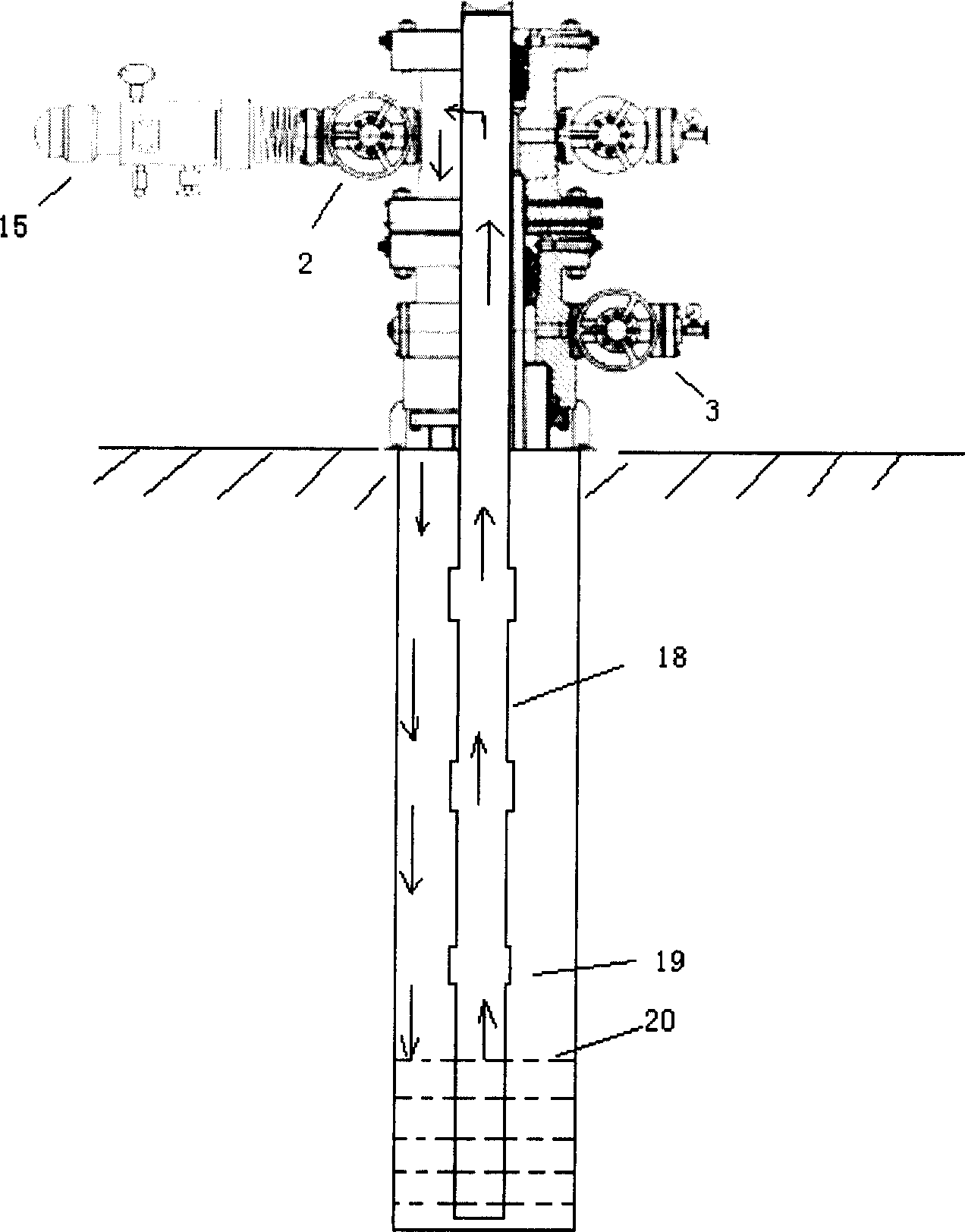

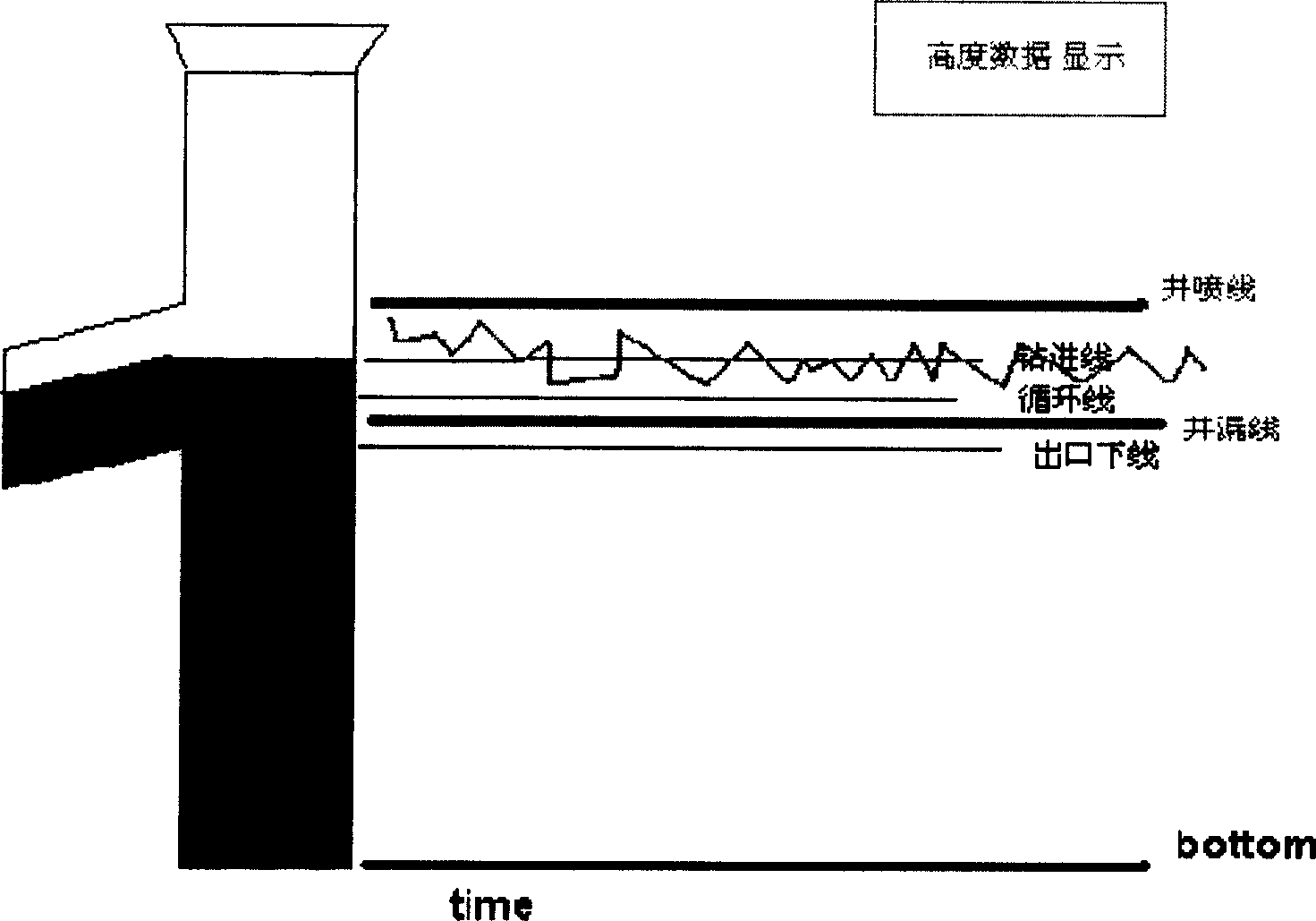

[0016] The components in the accompanying drawings are represented by the following reference signs: (1) well sealing device; (2) four-way internal and external valves; (3) casing head valves; (4) differential pressure liquid level gauge; (5) industrial control computer (6) loudspeaker; (7) mud pump; (8) mud tank; (9) shaft; (10) grouting pump; (11) cable; (12) mud water supply pipeline; (13) anti-overflow pipe; ( 14) pipeline; (15) sonar device; (16) radar liquid level gauge; (17) clamp-on flowmeter; (18) drill pipe; (19) drill pipe joint, (20) mud level in the well.

[0017] Such as figure 1 The monitoring method of the shown downhole liquid level monitoring system of the present invention is:

[0018] During the normal drilling / mud circulation process of the drilling rig, the liquid level in the wellbore is at the outlet of the overflow prevention pipe. At this time, the liquid level is monitored by the radar liquid level gauge (16) and the clamp-on flowmeter (17); the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com