Cooking fume remover

A range hood and chassis technology, which is applied in the field of range hoods with oil separation function, can solve the problems of range hoods polluting the environment, achieve good filtering effect, low cost, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

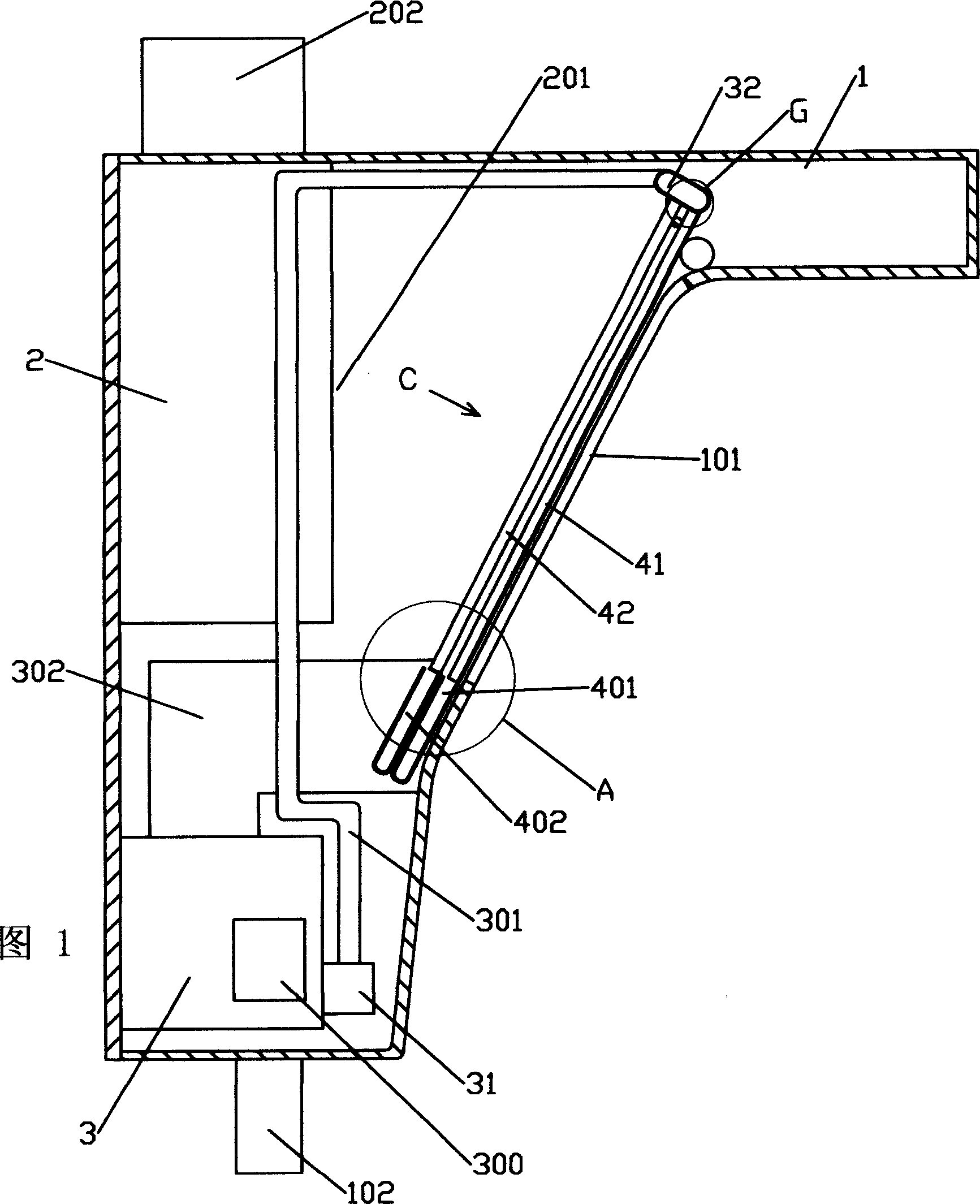

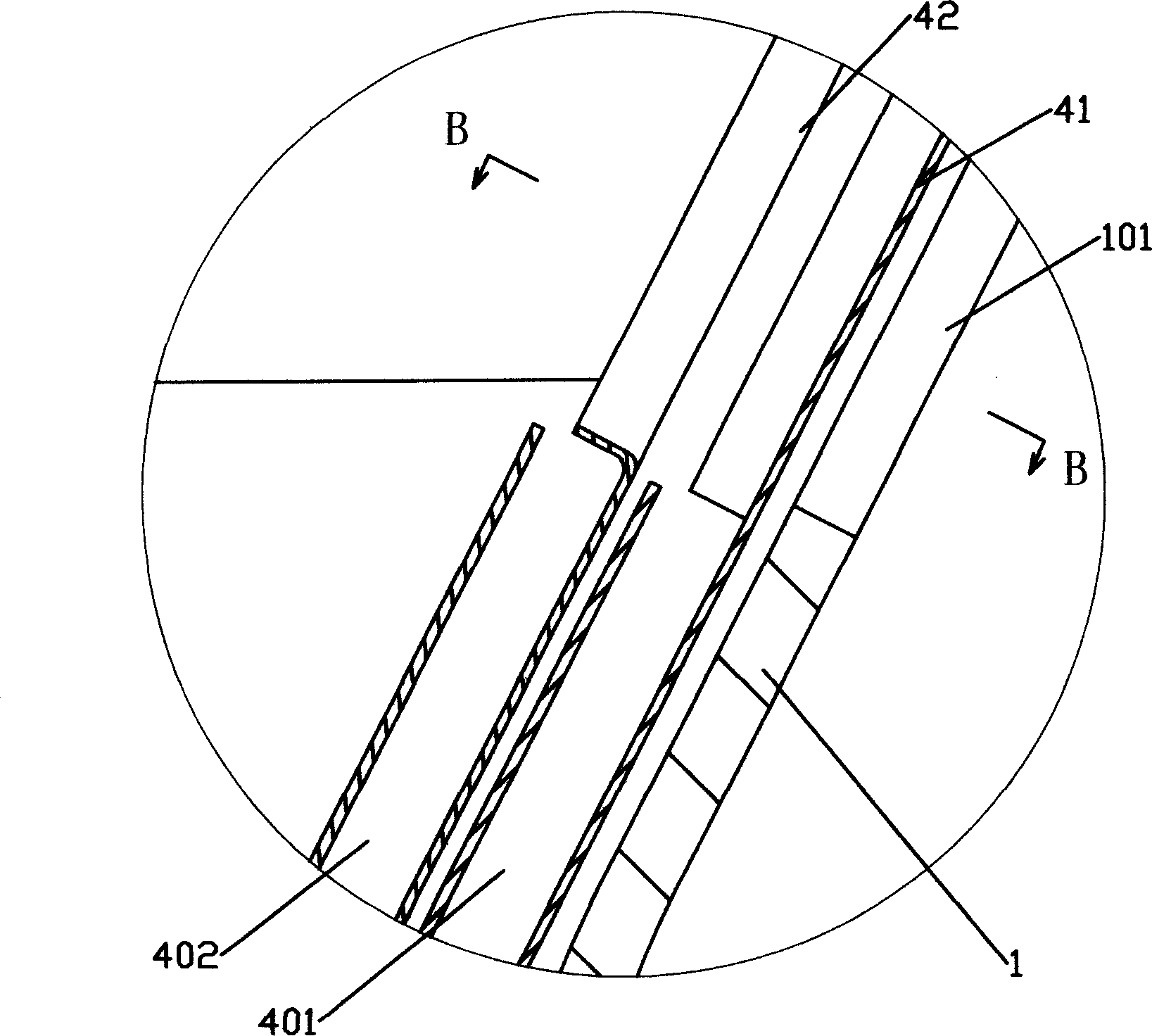

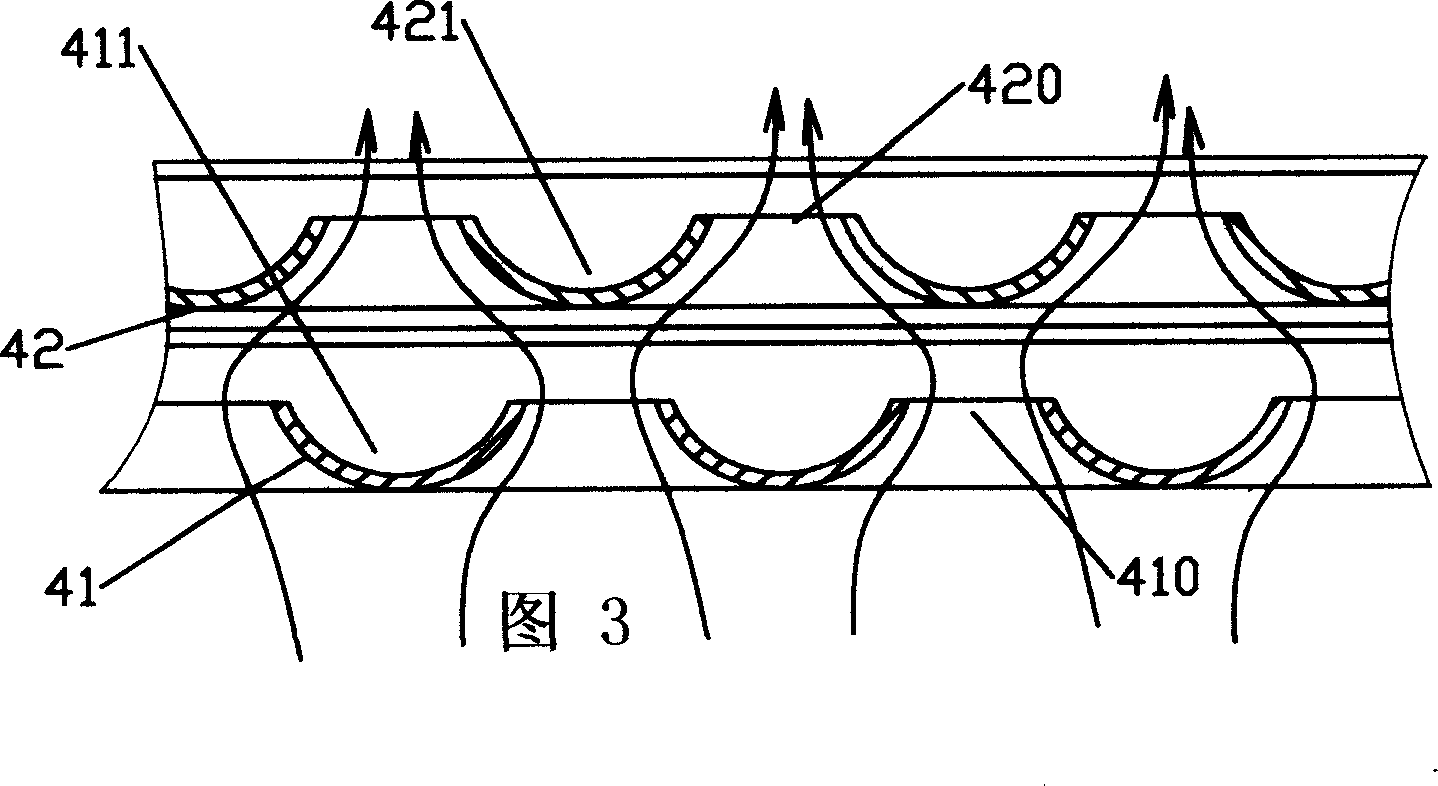

[0028] As shown in Fig. 1, the range hood includes a chassis 1 and a blower fan 2, etc., wherein the passage between the air inlet 101 of the chassis 1 and the suction port 201 of the fan is the suction passage, and the fan blade in the fan 2 is connected to the air outlet pipe. The passage between them is an exhaust passage, and two rows of cooling grilles 41 and 42 are fixed in sequence on the inner side of the air inlet 101 of the chassis; from Fig. 4 and Figure 5 It can be seen in the figure that the cooling grid is stamped with a thin plate. First, the thin plate is punched into a comb shape. The gap between the comb teeth is the tuyere 410, and then the water tank 411 and the eight cooling fins are stamped on the eight comb teeth. 41 forms a row of cooling grids on the same plane, and finally bends the lower part of the connecting comb teeth into a water collection tank 401 (see figure 2 The enlarged picture of the bottom of the sump 401), and the outer bottom of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com