Construction method of high quality relief well

A construction method and a technology of relief wells, which are applied in infrastructure engineering, dikes, coastline protection, etc., can solve the problems of difficulty in cleaning the mud in the hole, high construction cost, laborious and other problems, so as to reduce the construction cost, The effect of simple construction, time-saving and labor-saving construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

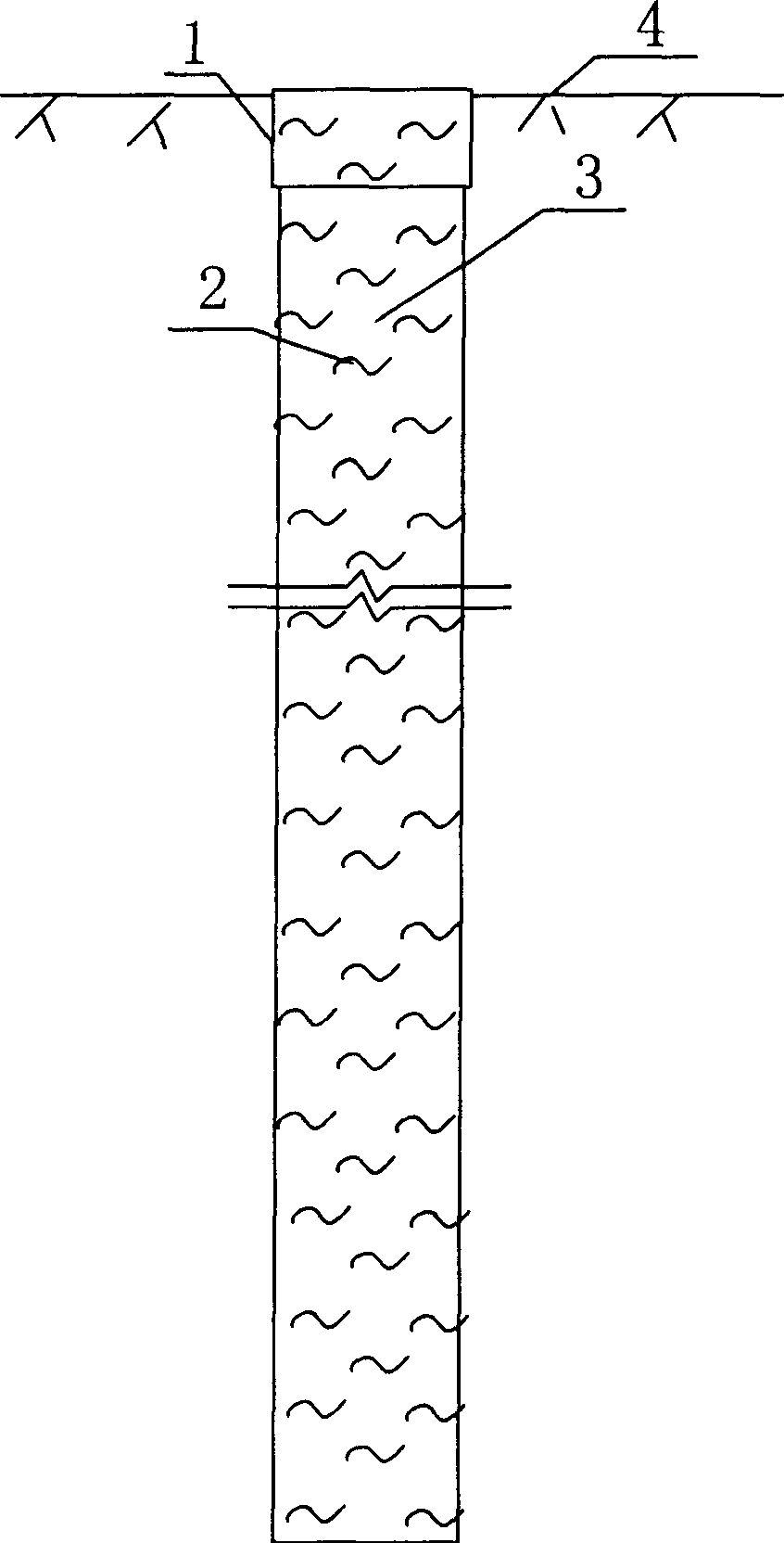

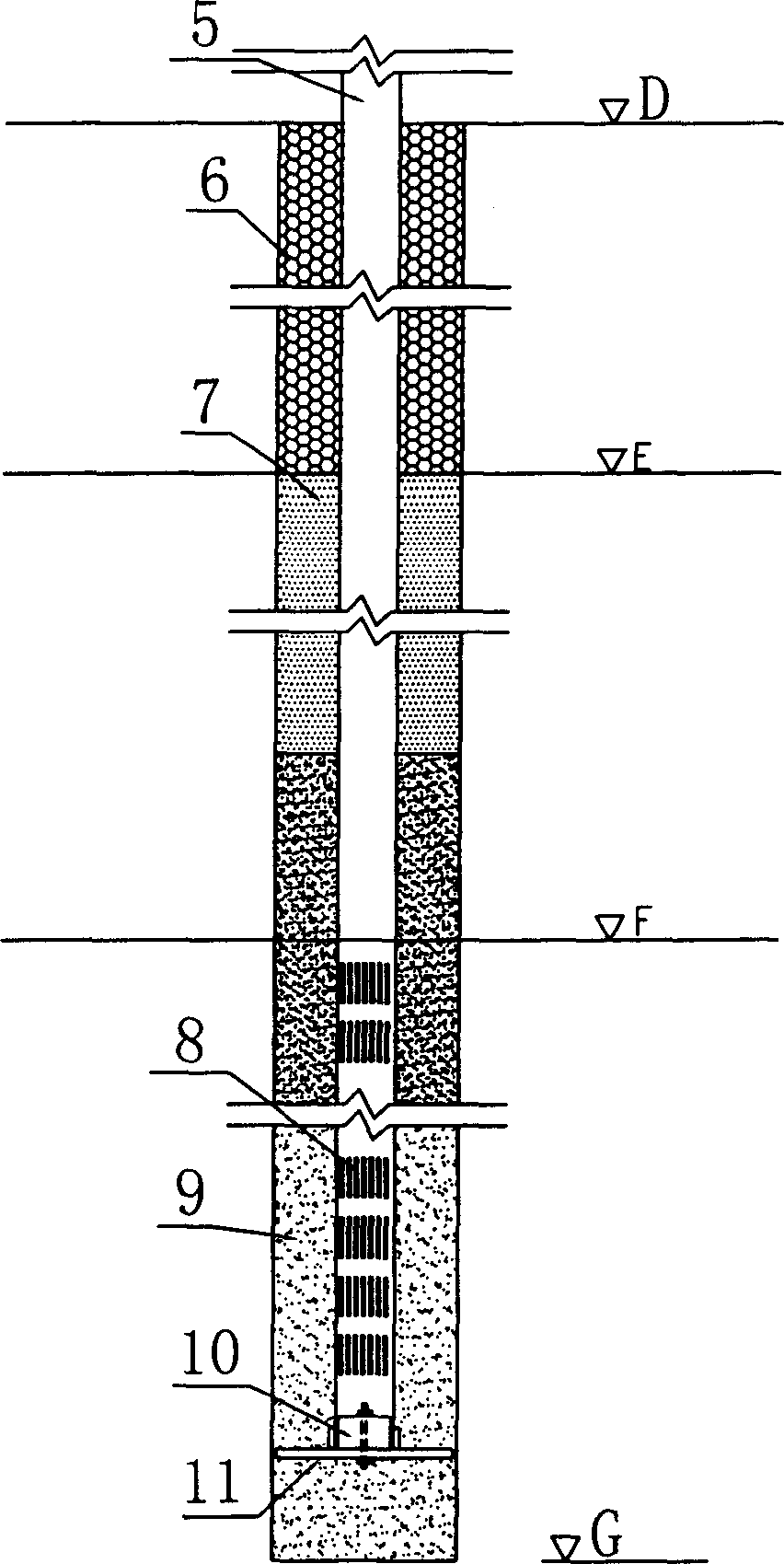

[0012] 1. Drilling construction of decompression well: reverse circulation drilling construction, directly use high-performance stable fluid to protect the hole; direct circulation drilling construction, first use mud wall to drill, and use high-performance stable fluid to replace protection after reaching the designed drilling depth Hole mud, and remove the mud skin on the hole wall; after cleaning the hole, use high-performance stabilizing fluid to protect the hole.

[0013] 2. Install and fix the drainage pipe of the relief well.

[0014] 3. Construction of pressure relief well filter material and other fillers.

[0015] 4. Relief well pumping, cleaning, and other follow-up work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com