Electrical connector

一种电连接器、连接器的技术,应用在连接、固定连接、电路等方向,能够解决提高制造成本、不能端子原封不动、连接器大型化等问题,达到容易制造、制造成本低、弹性变形容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

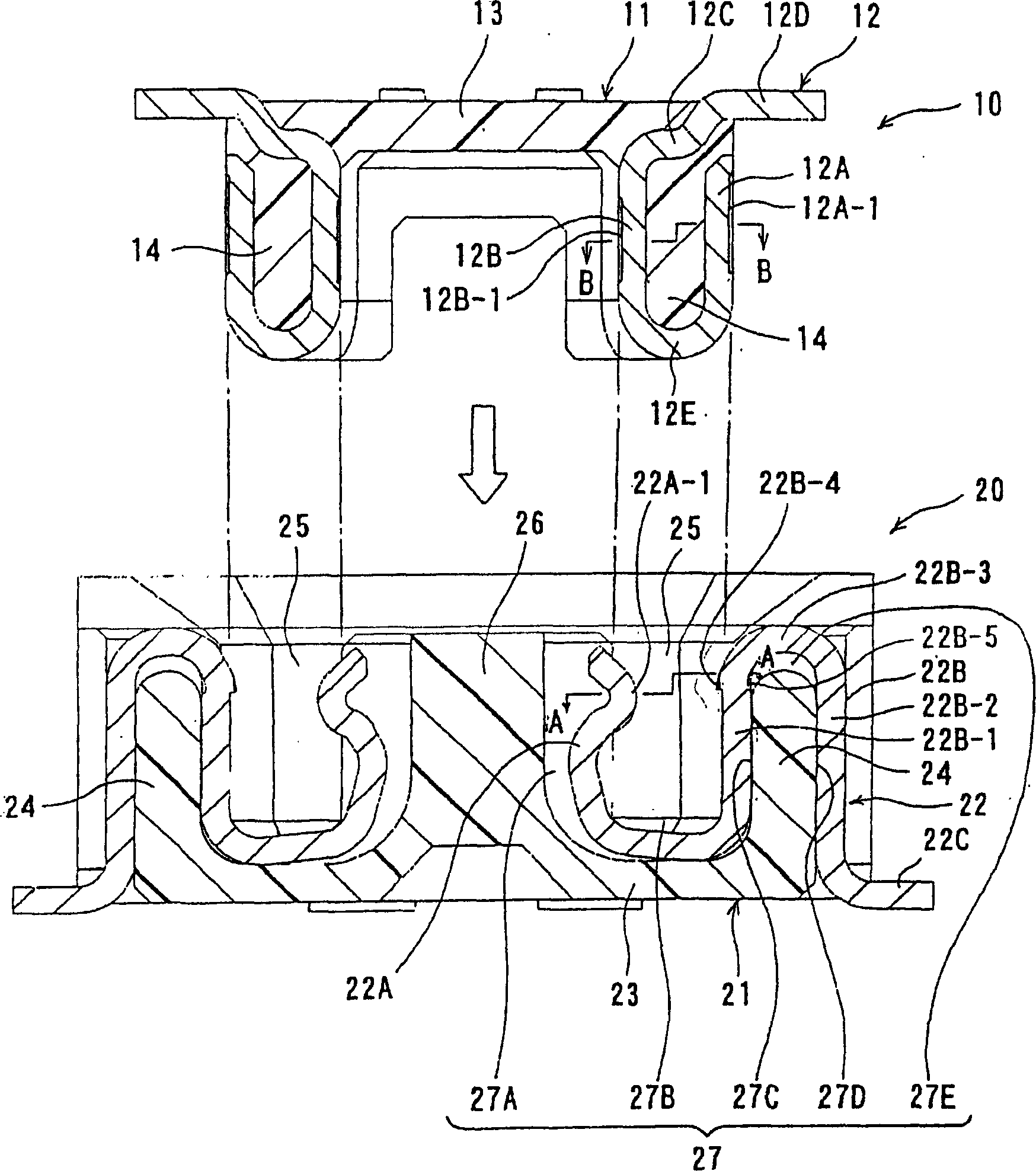

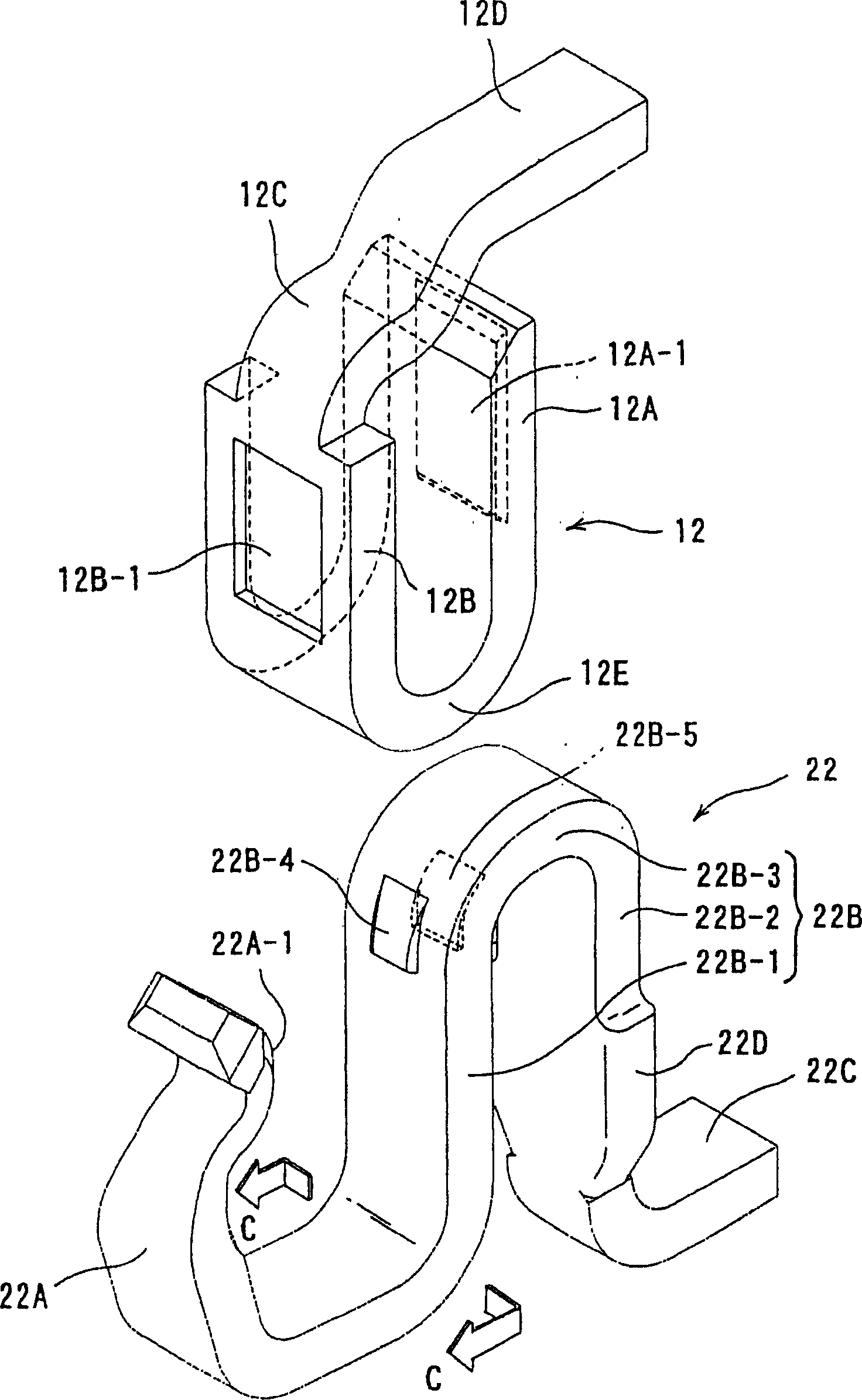

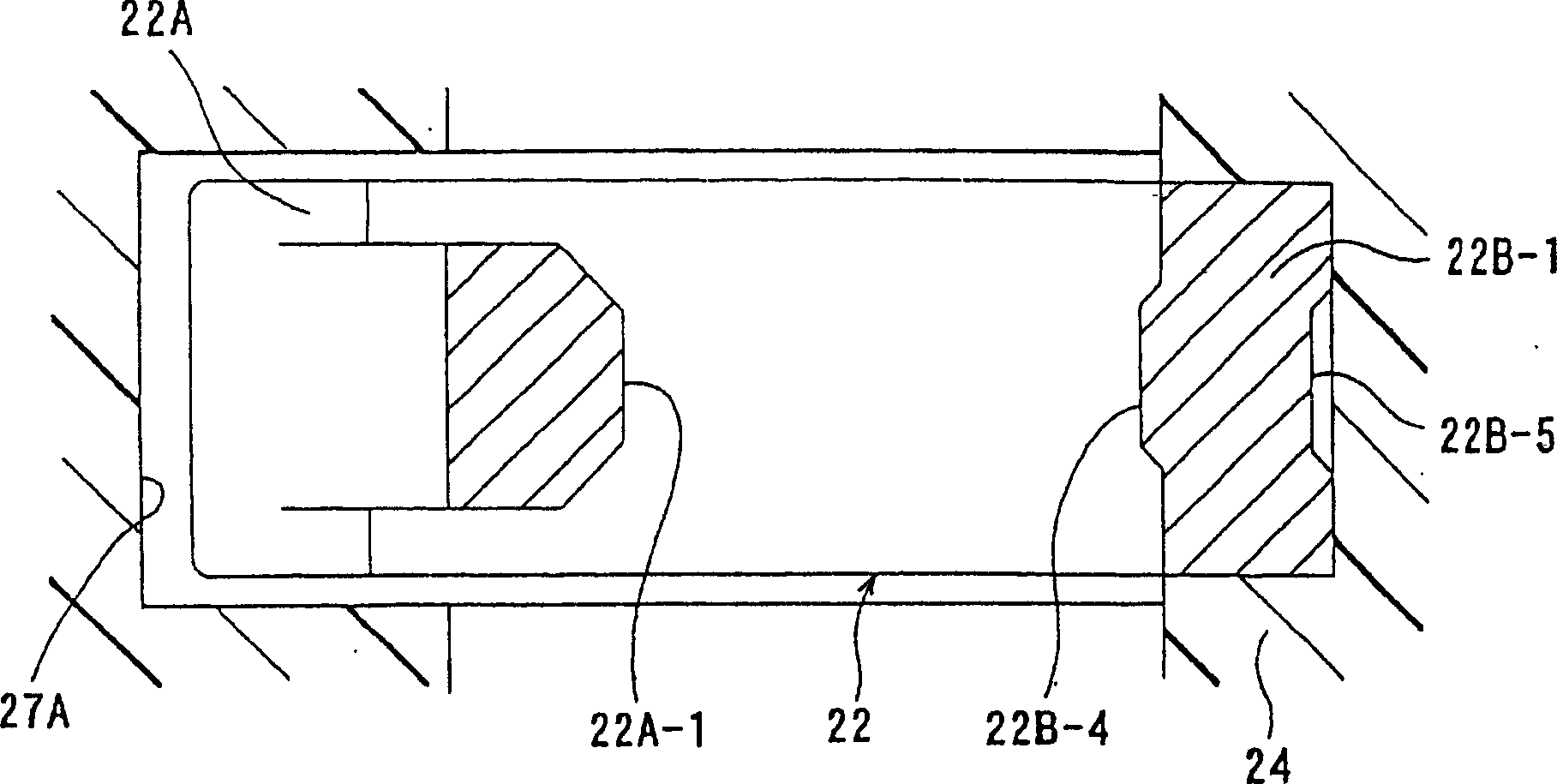

[0029] Below, according to figure 1 ~ Figure 3 illustrates an embodiment of the present invention.

[0030] figure 1 It is a cross-sectional view showing the male connector 10 and the female connector 20 that are connected to each other.

[0031] The male connector 10 has a housing 11 made of synthetic resin as an electrical insulating member, and a terminal 12 processed from a metal plate, and the terminal 12 is held by being integrally molded with the housing 11.

[0032] In the housing 11, two terminal holding wall portions 14 are formed upright from the base wall portion 13 with a predetermined interval therebetween. The distance between the two opposite inner wall portions of the two terminal holding wall portions 14 is set to be approximately the same as the thickness of the center wall portion of the target connector, that is, the female connector 20 described later. The distance between the two outer wall portions of the holding wall portion 14 is set to be approximatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com