Spark plug

A technology of spark plug and center electrode, applied in the field of spark plug and its manufacturing, can solve the problems of high glaze firing temperature, easy flashover of spark plug, reduced insulation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

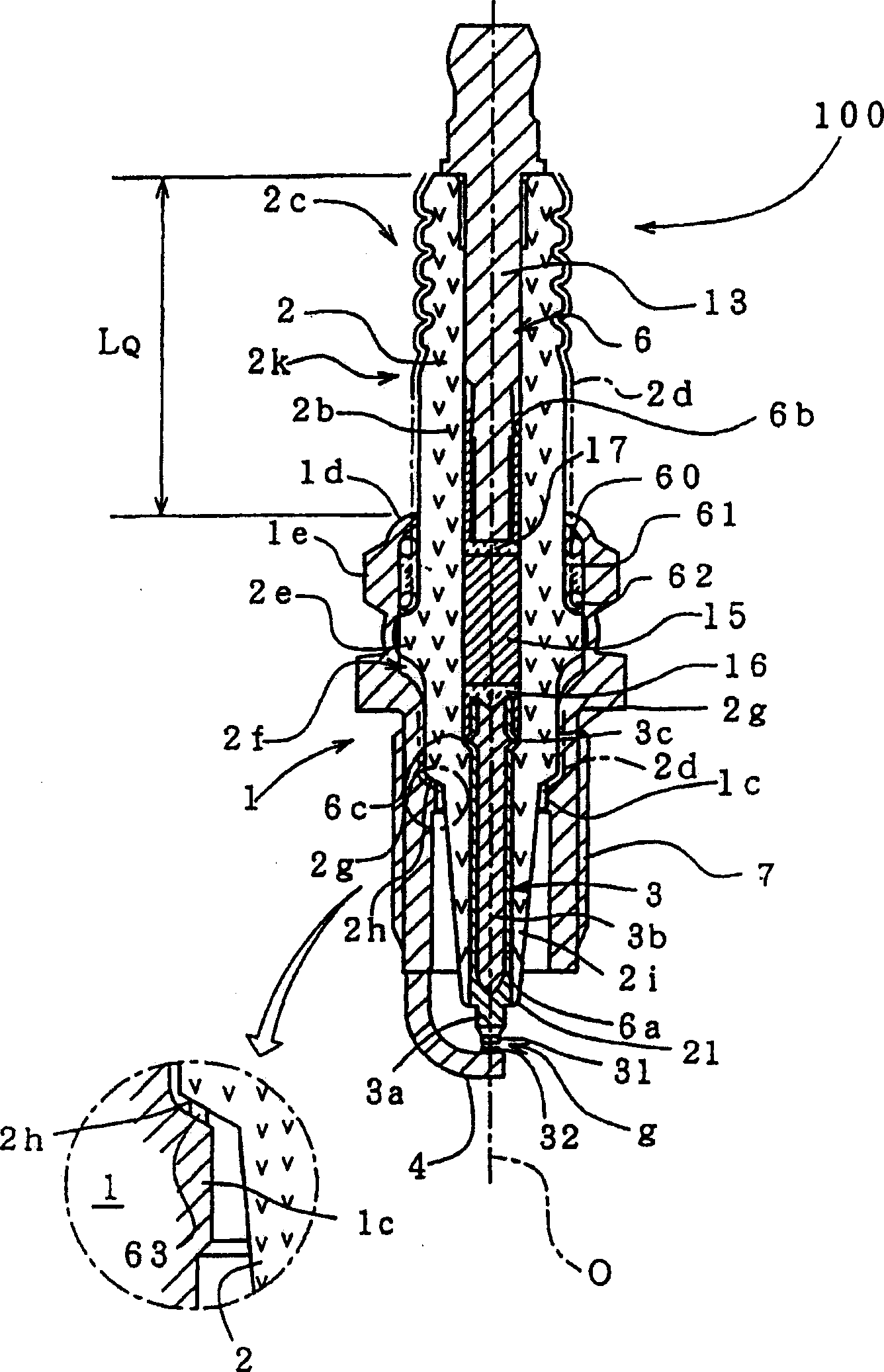

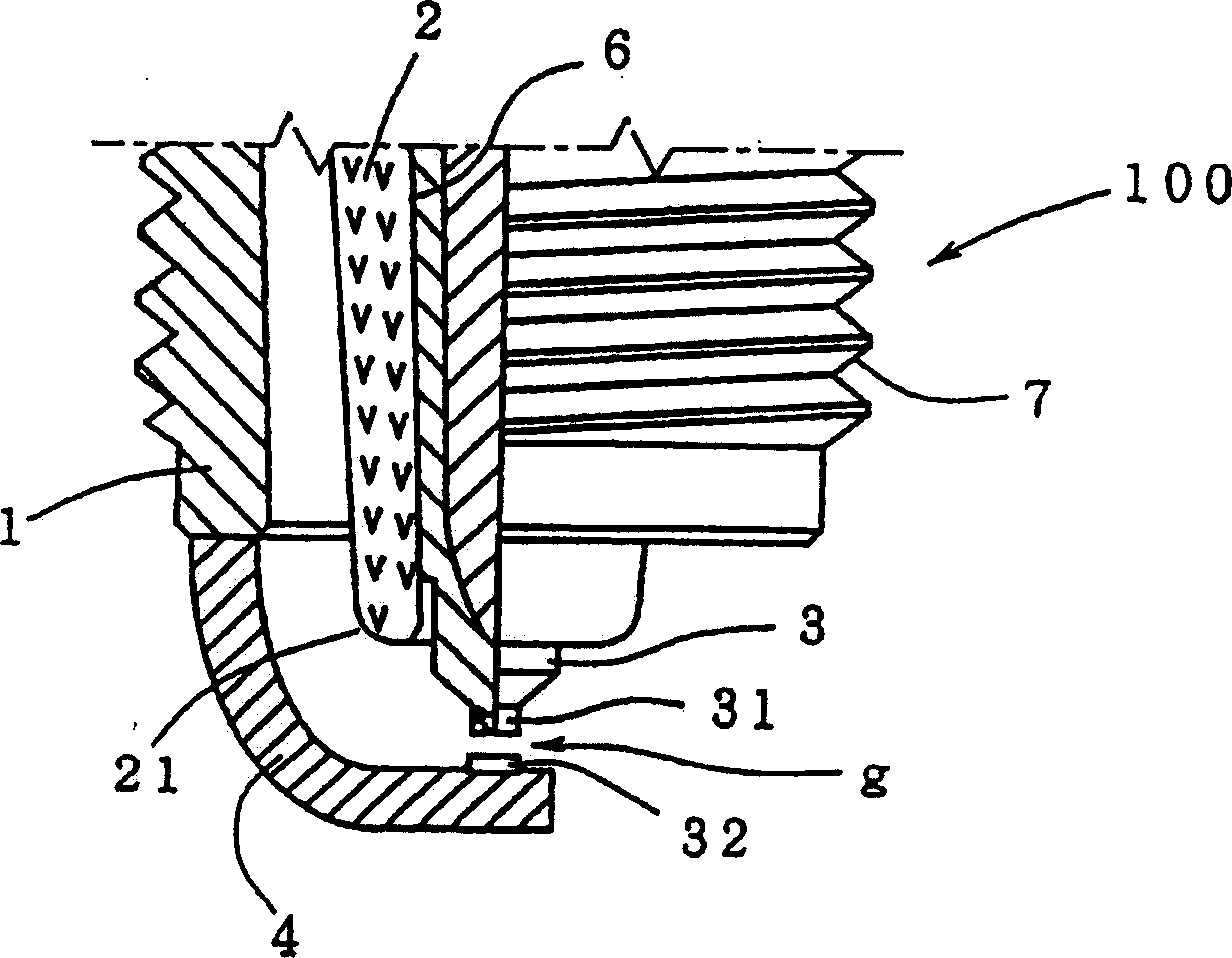

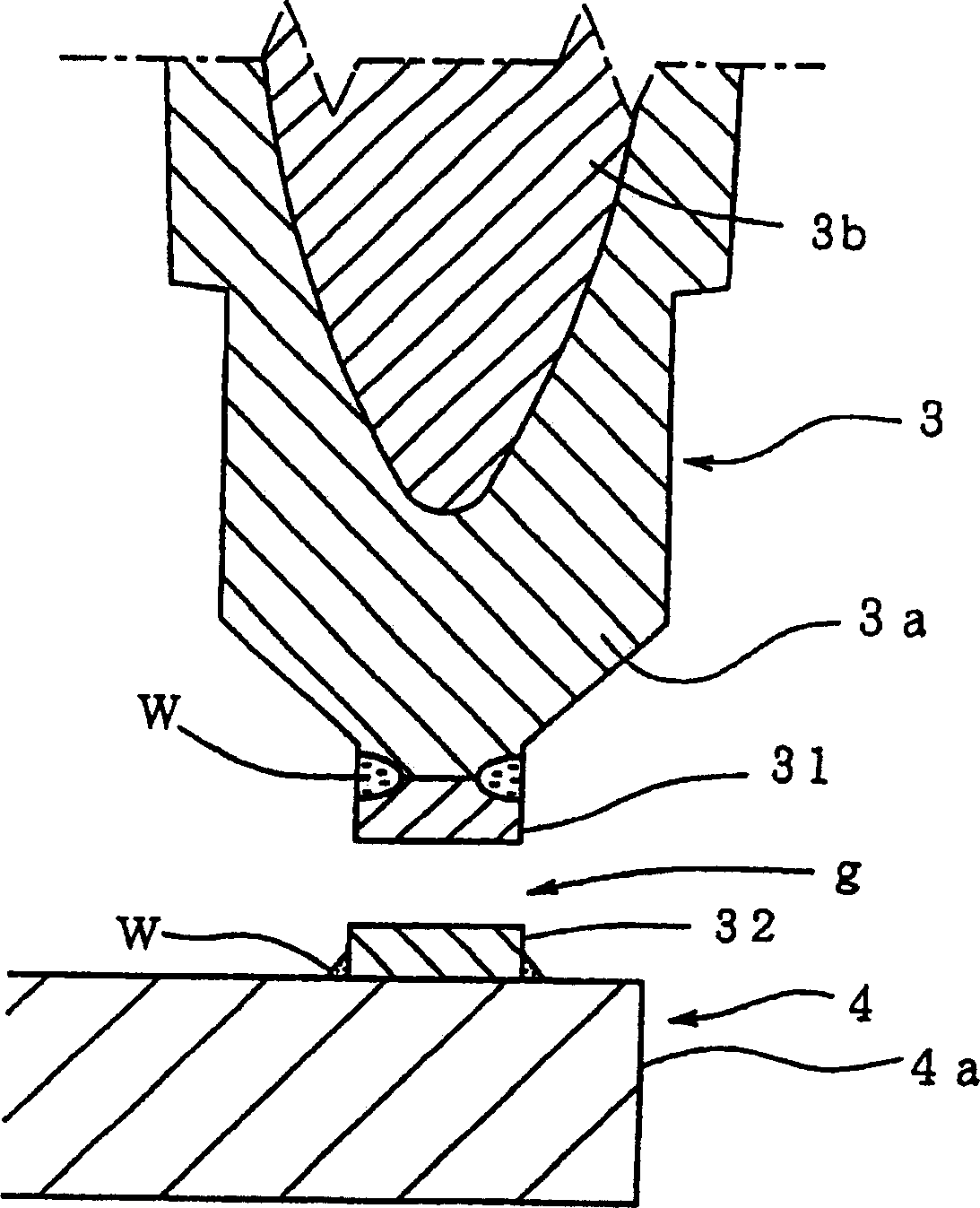

[0129] figure 1 and Fig. 2 shows an example of the spark plug according to the first mode of the present invention. The spark plug 100 includes: a cylindrical metal shell 1 , an insulator 2 , a center electrode 3 and a ground electrode 4 . The insulator 2 and the metal case 1 are fitted such that the tip of the insulator 2 protrudes from the metal case 1 . The center electrode 3 is disposed inside the insulator 2 such that the spark discharge portion 31 formed at the tip of the center electrode 3 protrudes from the insulator 2 . One end of the ground electrode 4 is connected to the metal shell 1 by welding or the like, while the other end thereof is bent to face the tip of the center electrode 3 . A spark discharge portion 32 facing the spark discharge portion 31 is formed on the ground electrode 4 . A spark discharge gap is formed between the spark discharge portions 31 and 32 facing each other.

[0130] A metal shell made of a metal like carbon steel forms a cylindrical...

Embodiment 2

[0177] An embodiment of the spark plug according to the second mode of the present invention will be described below. Except for the composition of the glaze layer, the structure of the spark plug of Example 2 is exactly the same as that of Example 1. Therefore, detailed descriptions other than the glaze layer are omitted, and they can be obtained by Figures 1 to 7 See very clearly. The glaze material for forming the glaze layer 2d includes: Si, B, Zn and Ba, which are main cationic components; at least one of Ti and Zr; and at least one of alkali metal components Na, K, Li. The content of the main cationic components is as follows: the weight percentage of Si is 20-40%, according to SiO 2 In conversion, the weight percentage content of B is 20-35%, according to B 2 o 3 In conversion, the weight percentage of Zn is 15-25%, converted by Zn, and the content of Ba is 10-23%, converted by BaO. The total amount of Ti and Zr is 2-10%, as TiO 2 and ZrO 2 convert. The total w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com