Conductive paste, solar cell prepared from conductive paste and manufacturing method

A solar cell and conductivity technology, which is applied in the field of conductive paste and solar cells prepared therefrom and manufacturing, can solve the problems of affecting the performance of solar cells, poor EL detection performance, poor tensile performance, etc., and achieves ohmic contact Excellent, high stability, excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

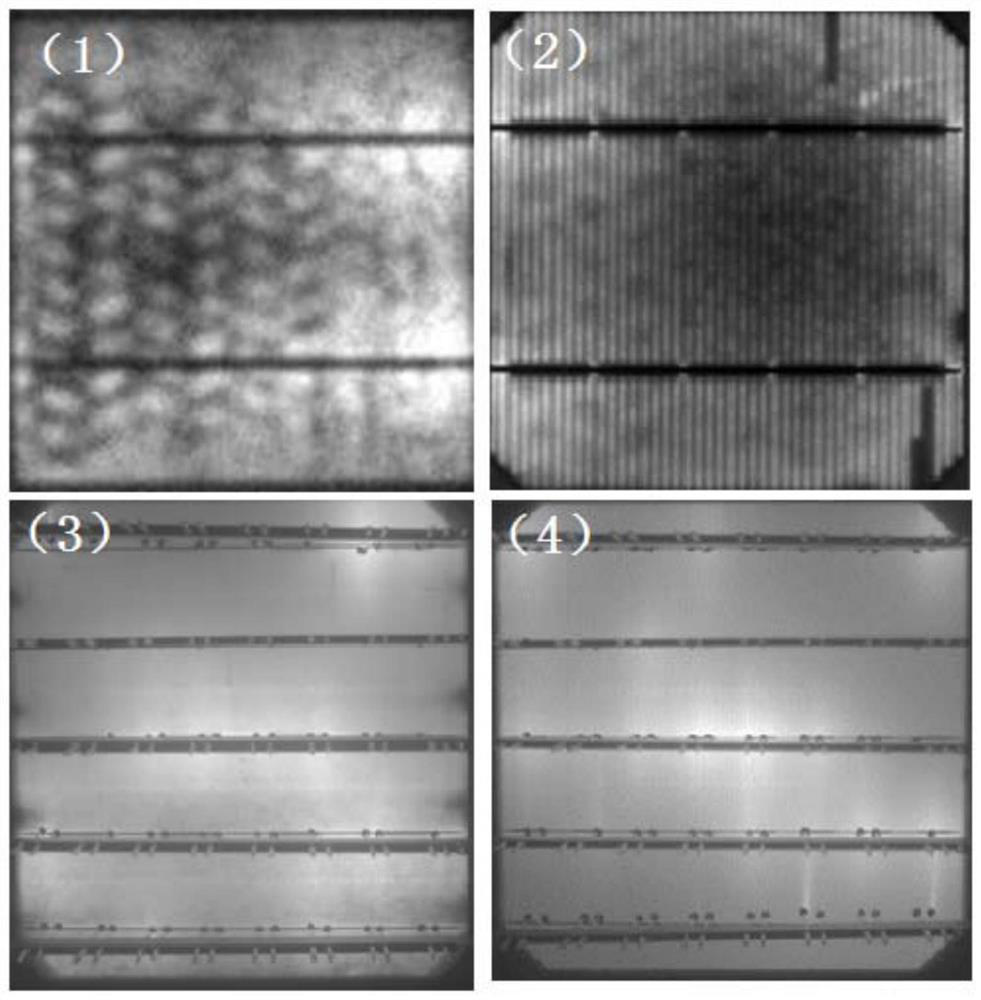

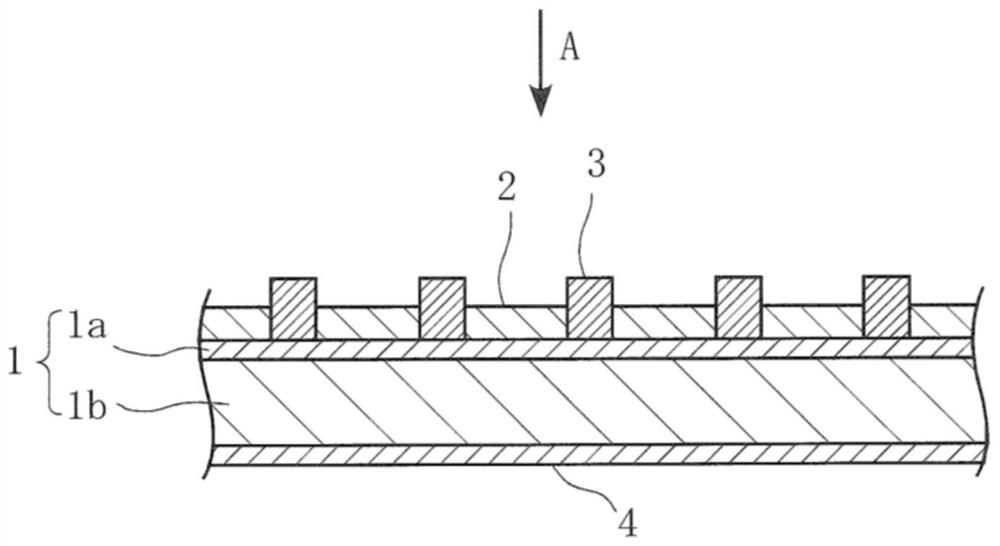

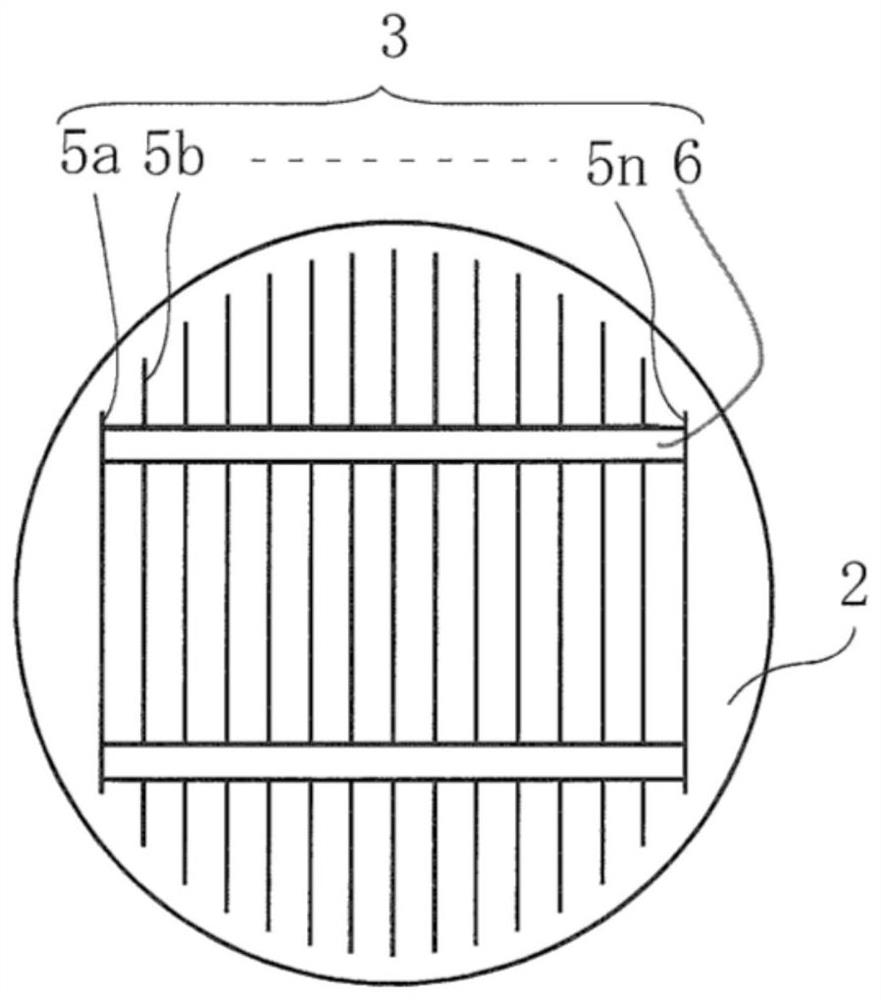

Image

Examples

Embodiment 1

[0093] 〔Prototype making〕

[0094] Making Tellurium Glass : Prepared TeO 2 、 Bi 2 o 3 、WO 3 , ZnO, Al 2 o 3 , LiO 2 , B 2 o 3 etc., according to the ratio shown in Table 1-1, Table 1-2, and Table 1-3, these glass raw materials were weighed and prepared, and finally small sample glasses A-1 to A-5 were made.

[0095] Table 1-1

[0096]

[0097] Table 1-2

[0098]

[0099] Table 1-3

[0100] A-5 TeO2 B2O3 weight% 93 7 Mol% 85.3 14.7

[0101] in,

[0102] A-4 is an embodiment of the tellurium-based glass defined by the present invention that does not substantially contain lead and uses lithium bismuth tellurium as an essential component. The rest is a comparative example, specifically,

[0103] A-1 is bismuth telluride tungsten glass (formulation in patent document 7);

[0104] A-2 is a glass in which bismuth telluride zinc is the main component and aluminum is added.

[0105] A-3 is a glass in which bismuth tellur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com