Automatic spray-paint device

An automatic painting and spray gun technology, which is applied in spraying devices, spraying devices with movable outlets, etc., can solve problems such as difficulty in the testing stage, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

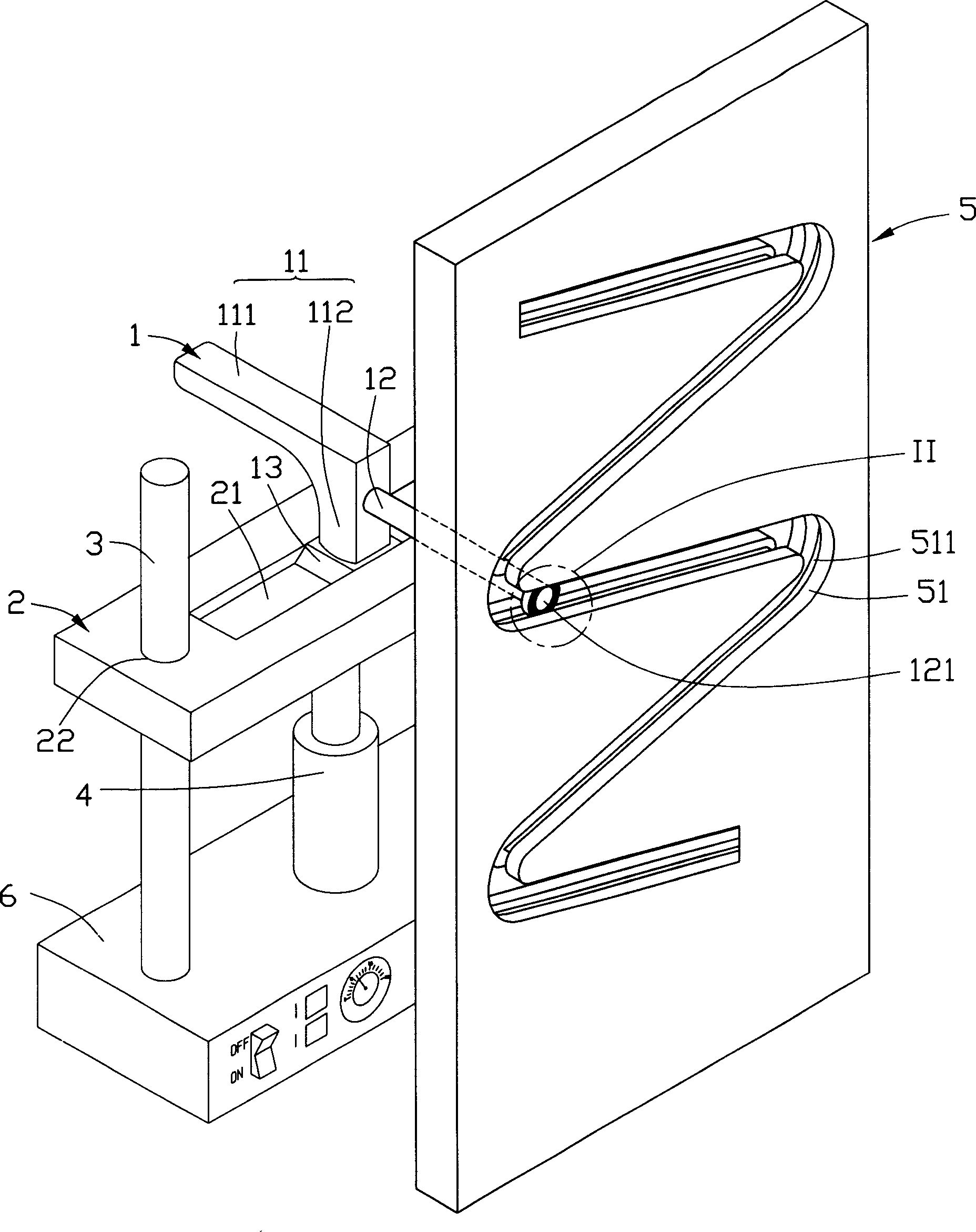

[0008] see figure 1 , a preferred embodiment of the present invention comprises a spray gun 1, a platform 2, a group of guide pillars 3, a push rod 4, a guide plate 5 and a console 6; wherein the spray gun 1 is slidably installed on a surface of the platform 2 Above, the platform 2 is slidably installed on the guide post 3, the ejector rod 4 is supported on the side of the platform 2 opposite to the surface on which the spray gun is installed and enables the platform 2 to slide up and down along the guide post 3, and the guide plate 5 is fixed on one side of the platform 2 ; One end of the guide post 3 and the mandrel 4 is all fixed on the console 6 .

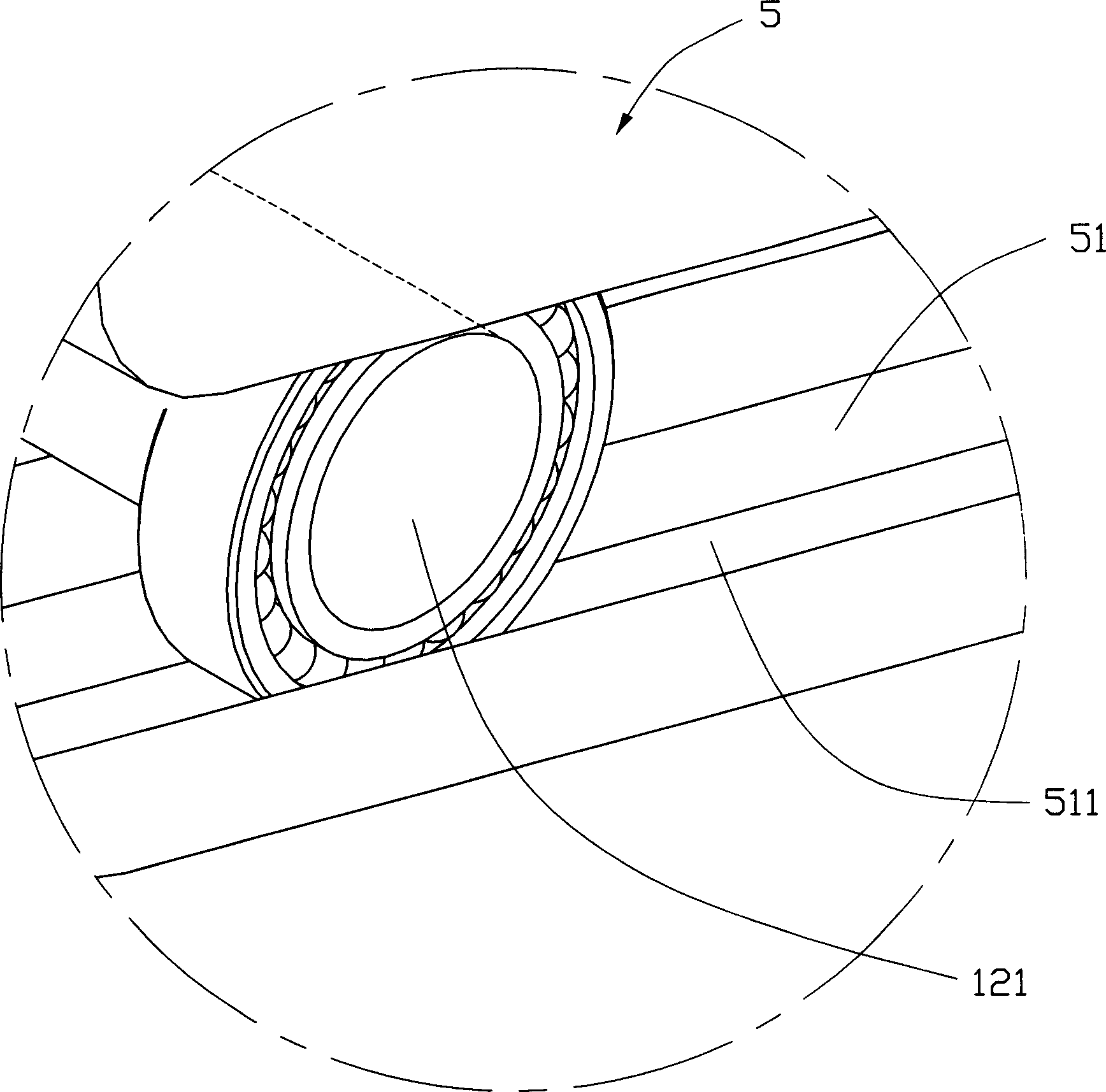

[0009] Spray gun 1 comprises a body 11, a connecting rod 12 and a slide block 13; Body 11 is roughly L-shaped, comprises the spray gun tube 111 that links to each other and spray gun handle 112, and connecting rod 12 is installed in the spray gun tube 111 rear end and is connected with the spray gun tube 111 In parallel, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com