Knife vibration type mechanism for cutting sponge

A vibrating and cutting machine technology, which is applied in metal processing and other directions, can solve the problems of increasing the labor intensity of the staff, the trouble of manually fixing the sponge, and the inability to cut special-shaped materials, etc., to achieve the effect of ensuring physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

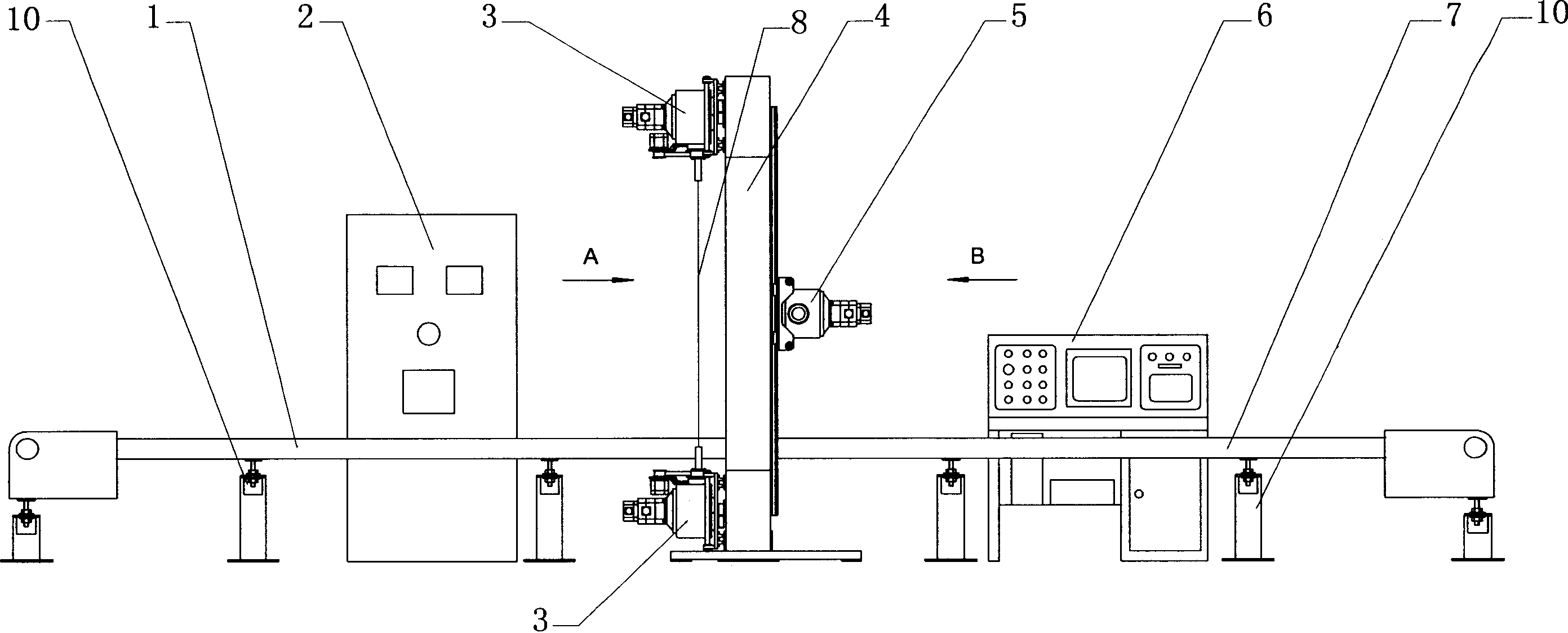

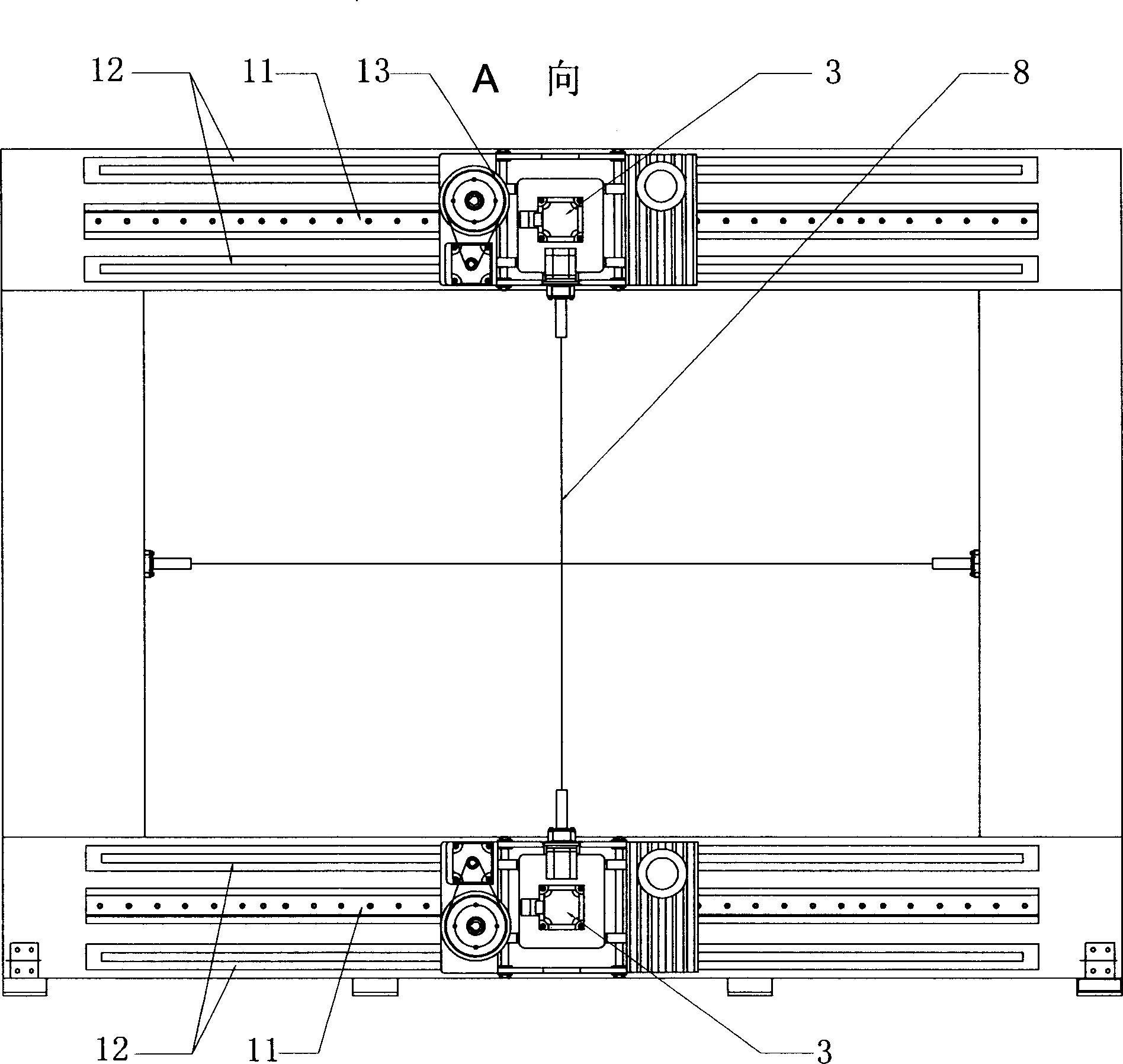

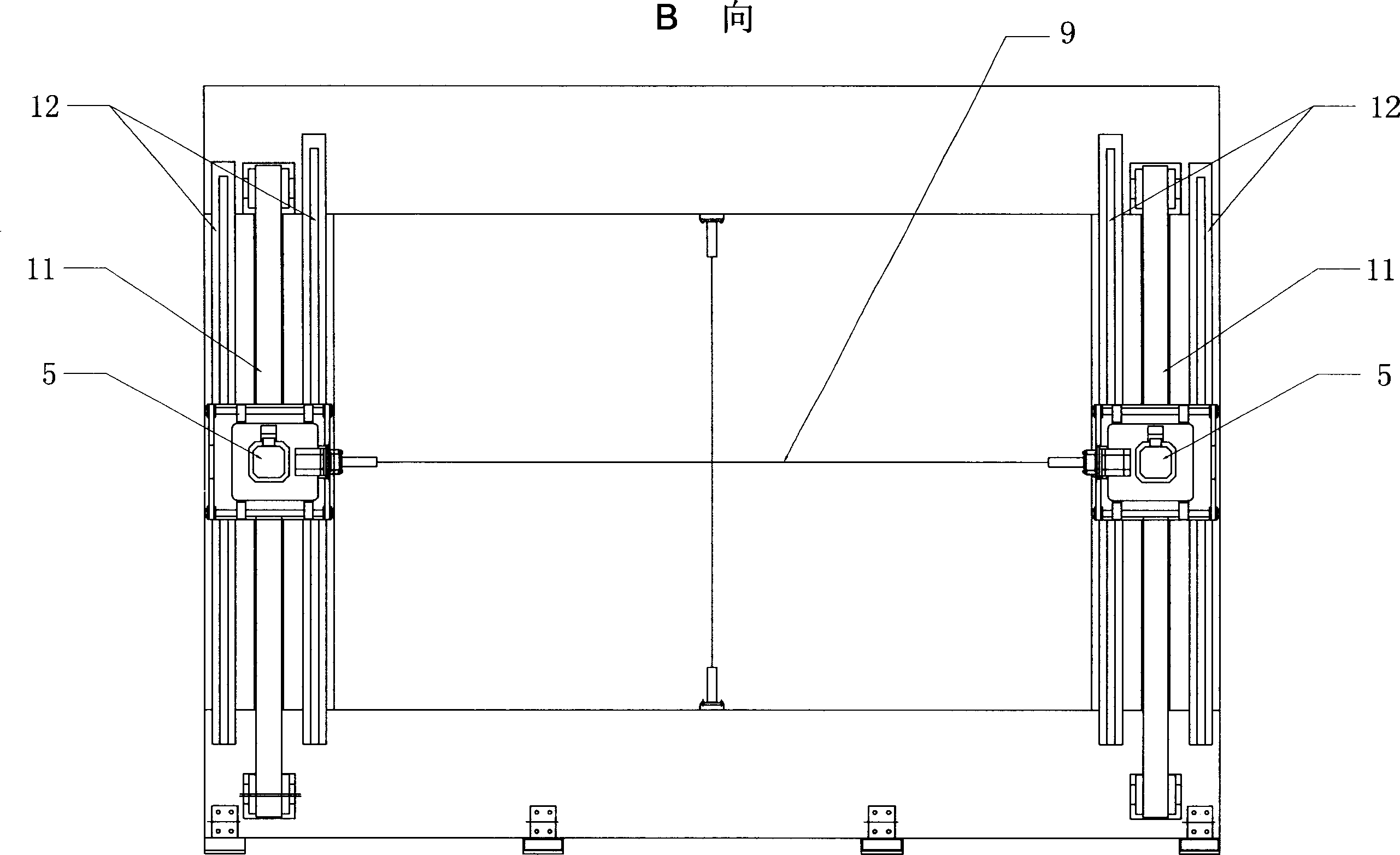

[0013] The present invention is described in further detail below in conjunction with accompanying drawing (embodiment):

[0014] Refer to attached Figure 1-3 , the present invention consists of a left working platform 1, an electric control wiring cabinet 2, a longitudinal vibrating head 3, a gantry frame 4, a transverse vibrating head 5, a numerical control computer system 6, a left working platform 7, a vertical knife 8, a horizontal knife 9, and a supporting frame 10. Slide rail 11, support beam 12, vibration head driving mechanism 13 is composed, a gantry frame 4 is set between the left working platform 1 and the right working platform 7, the working platform is supported by the support seat 10, and a longitudinal The vibrating head 3 and the horizontal vibrating head 5, the vertical knife 8 is set between the 3 vertical vibrating heads, the horizontal knife 9 is set between the 5 horizontal vibrating heads, and the electric control wiring cabinet 2 and the numerical con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com