Apparatus for calibrating gas detector in site, and method of gas distribution

A gas detector, on-site calibration technology, applied in chemical instruments and methods, instruments, measuring devices, etc., can solve the problems of high price, high cost, long time, etc., and achieve the effect of low cost, low power consumption and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

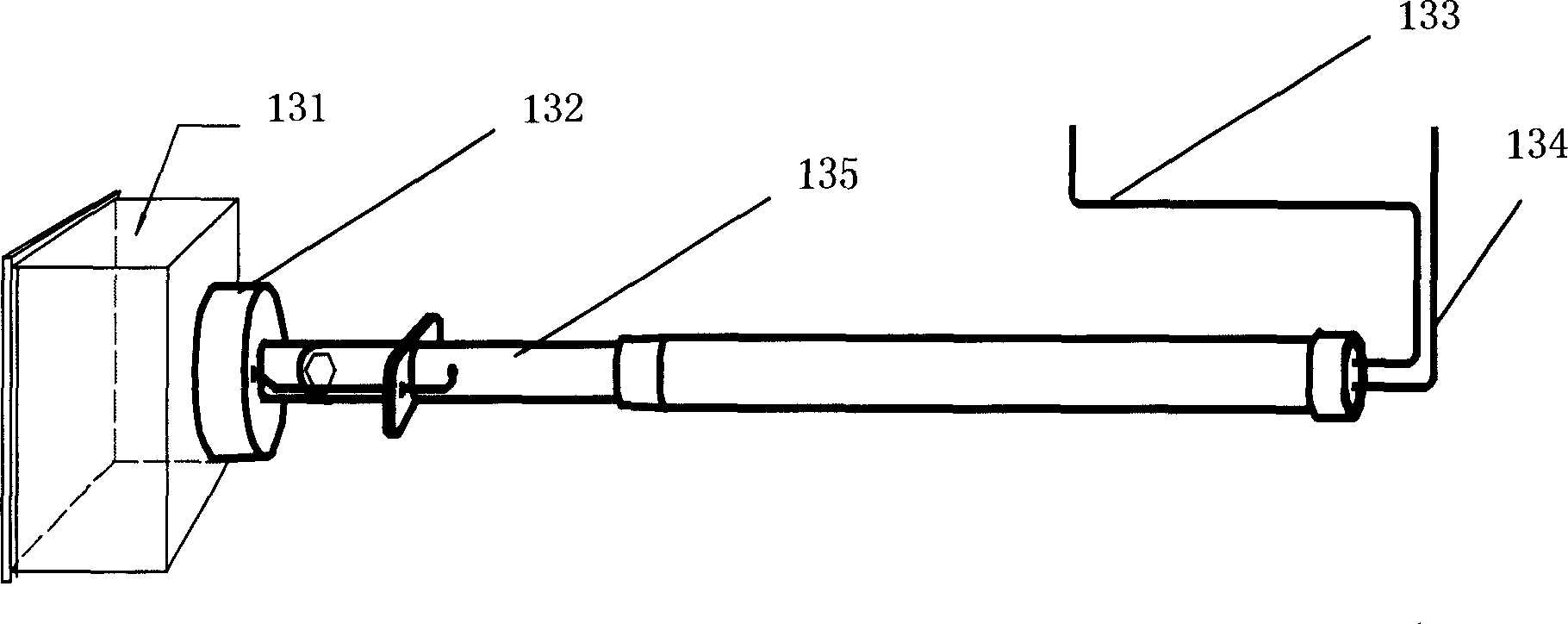

[0071] It is estimated that about 10ml of gas is consumed, so a bottle of gas can be used to calibrate more than 2000 gas alarms. And the high-pressure gas cylinder 12 itself has a pressure reducing valve, and the outlet pressure is between 0.5Mpa and 0.8Mpa. It also includes a barometer to indicate the internal pressure of the high-pressure gas cylinder.

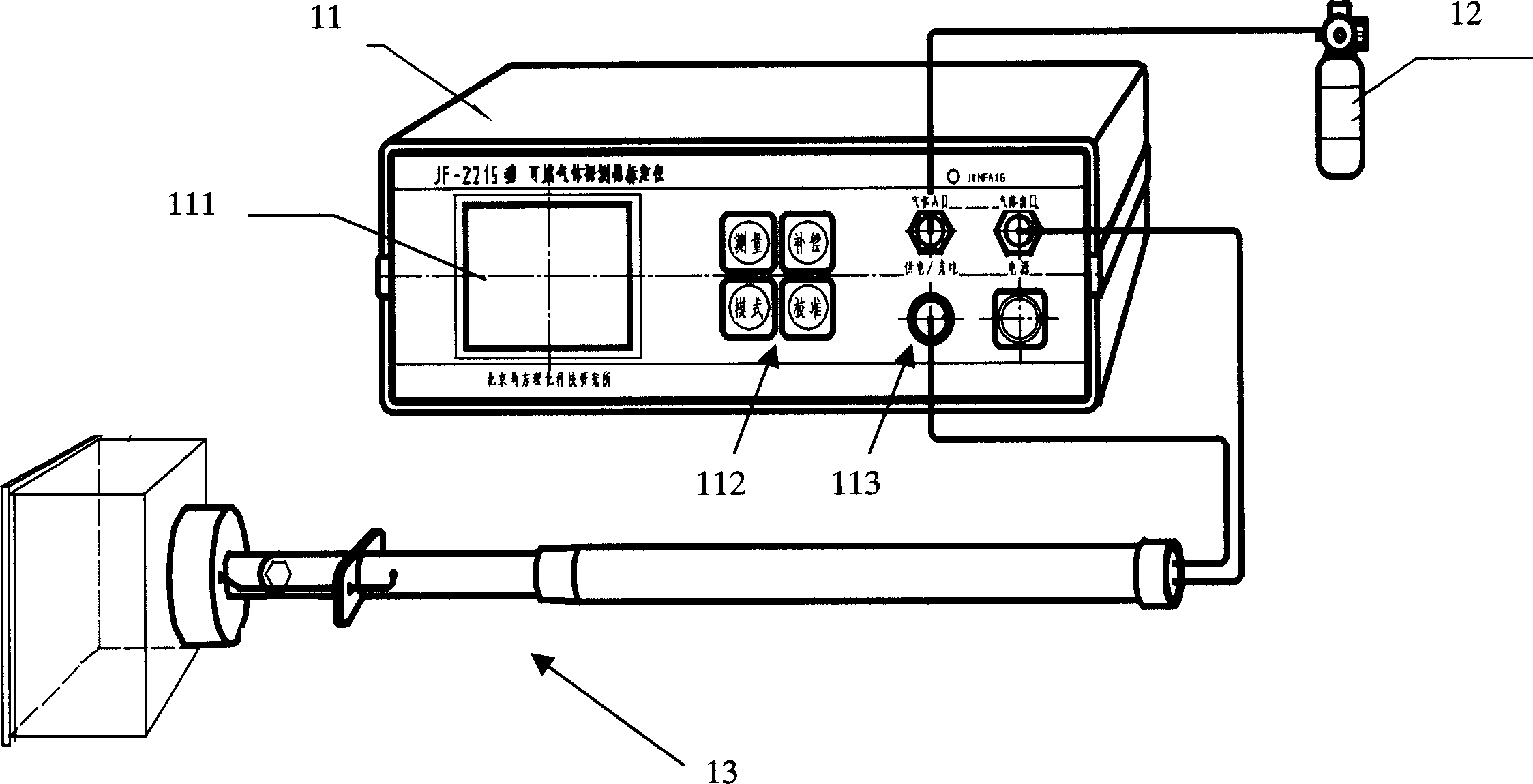

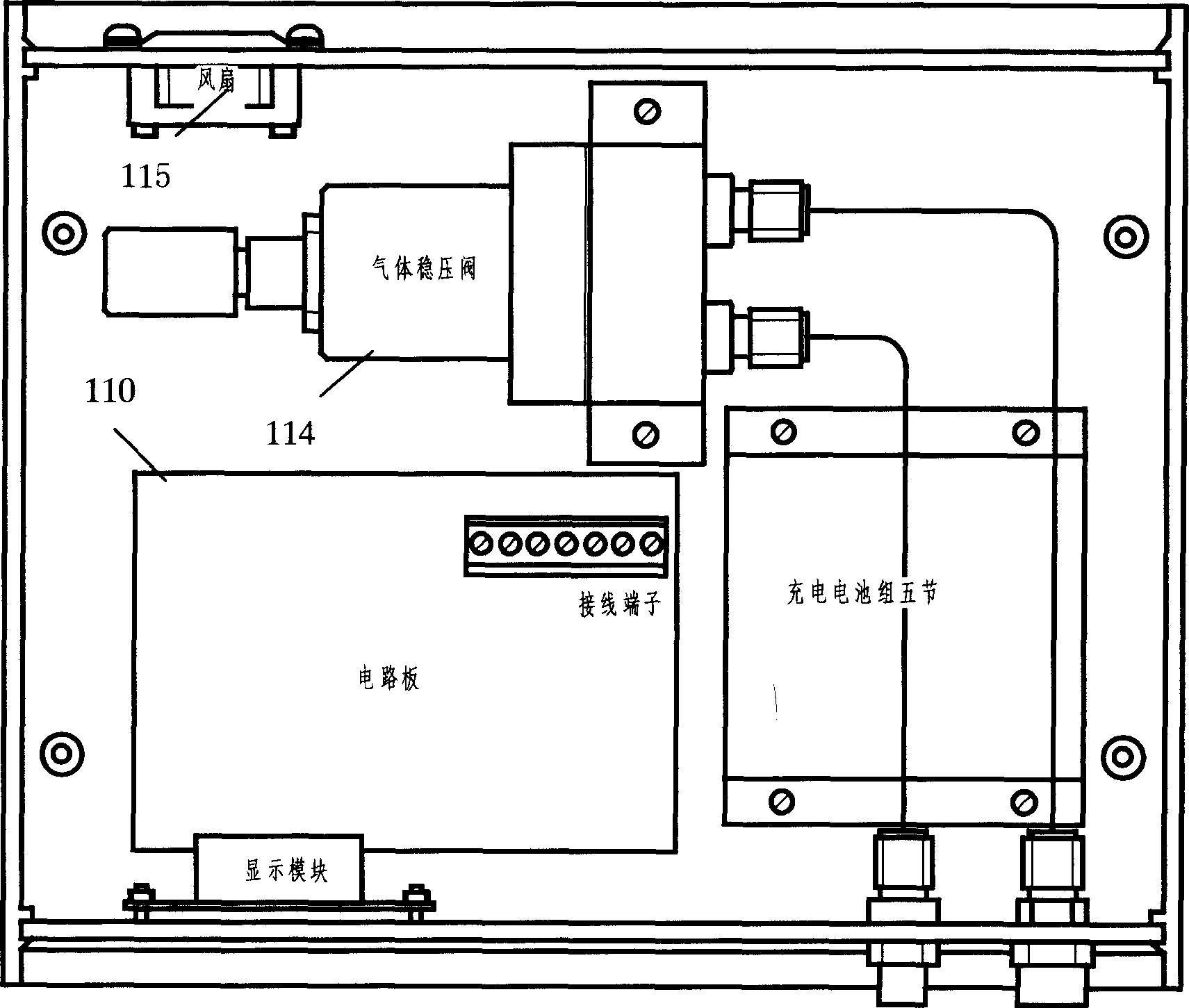

[0072] combine figure 1 and figure 2 As shown, the host 11 is mainly composed of a control circuit board 110, a display screen 111, a keyboard 112, various interfaces 113, a gas regulator valve 114 and a battery module (not shown in the figure). At the same time, the gas detector field calibration instrument of the present invention can also include a battery charger, which can charge the battery module of the gas detector field calibration instrument. After the gas detector field calibration instrument is fully charged, it can be used for 48 hours for continuous calibration. More than 400 gas alarms.

[0073] At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com