Method for synthesizing Nano balls of cuprous oxide, and application of Nano balls of cuprous oxide

A technology of cuprous oxide and nanospheres, applied in the application field of synthesizing cuprous oxide nanospheres and cuprous oxide nanospheres, can solve the problems of high reaction temperature, unfavorable large-scale production, long reaction time, etc., and achieves wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

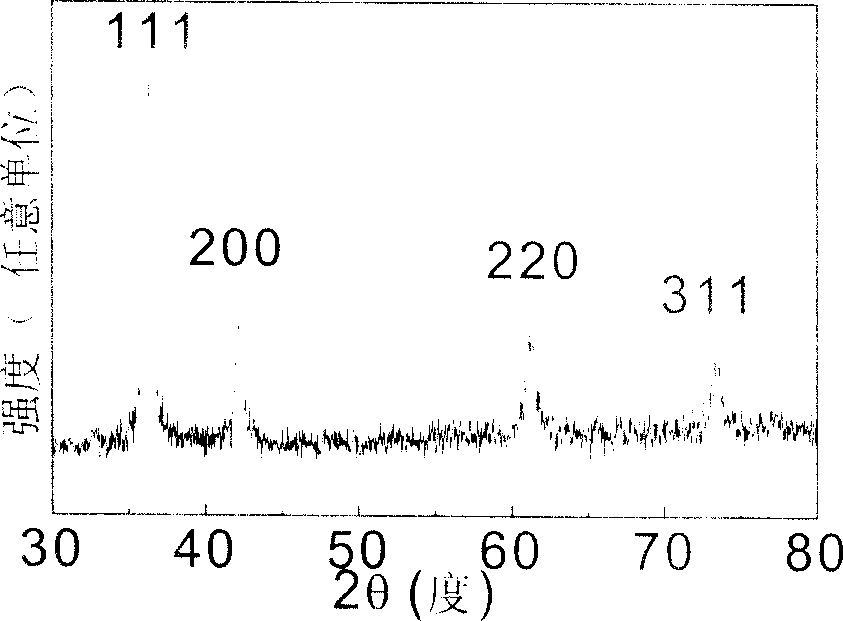

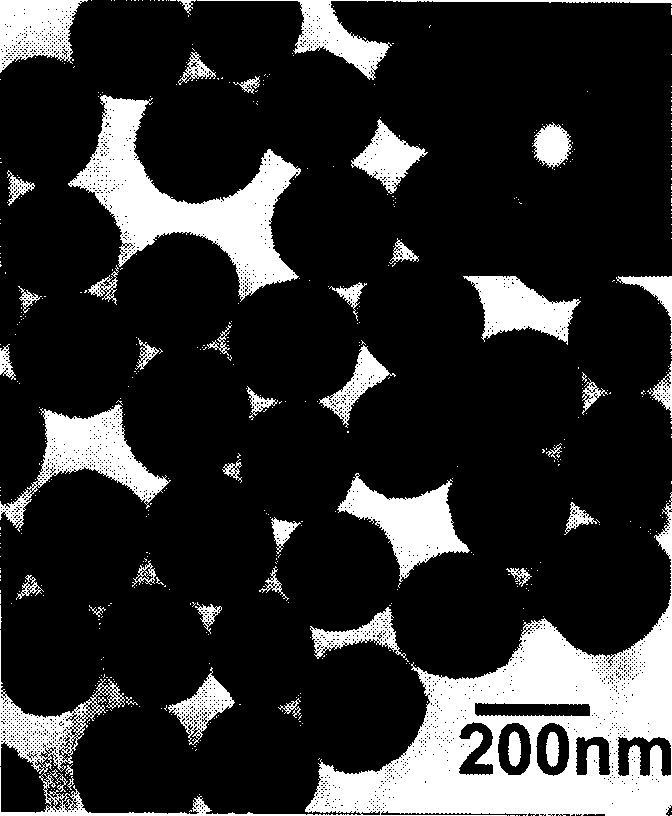

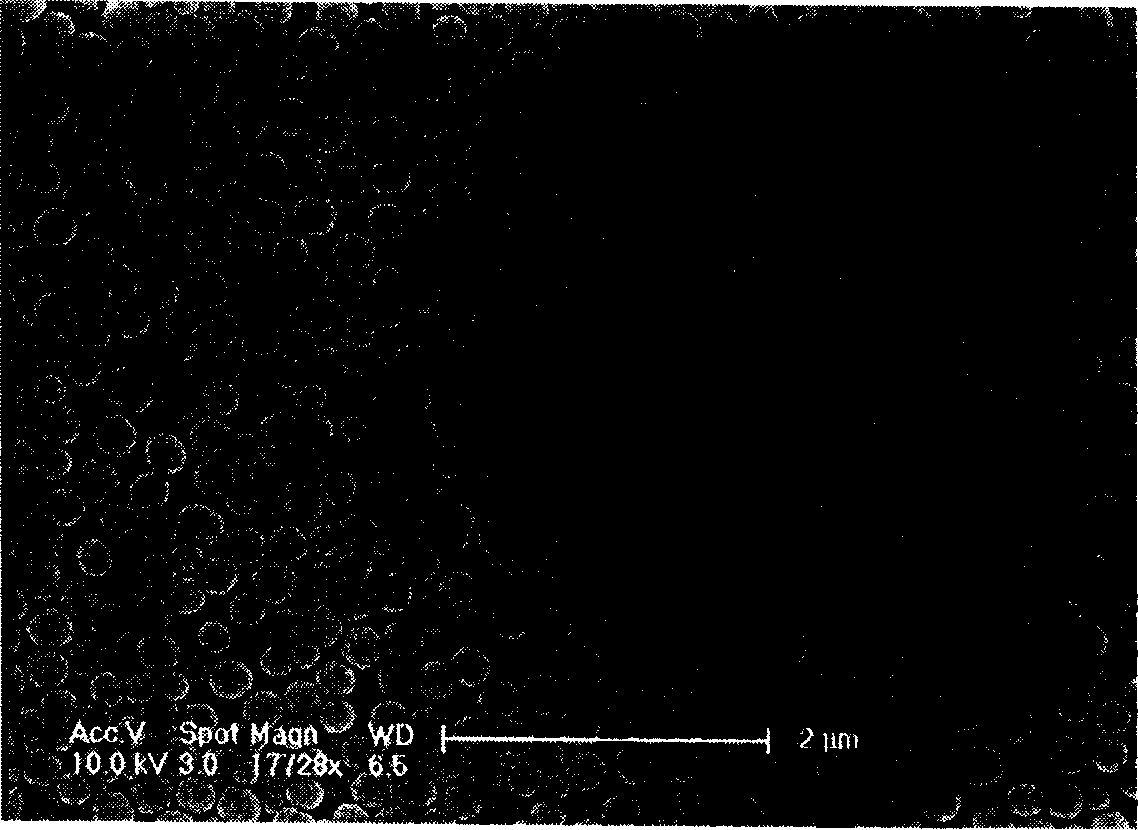

[0033] Get 0.4g analysis pure copper acetate (Cu(CH 3 COO) 2 .H 2 O) be placed in the three-necked flask of 100ml, add 30ml N, N dimethylformamide dissolves, add 0.165gPVP (molecular weight 30000), stir and dissolve, add 0.04g sodium borohydride again, utilize oil bath or water bath to heat to After 2 minutes at 80°C, the color changed to orange-red, and the orange powder was obtained by centrifugation. The product is identified as cubic phase cuprous oxide by X-ray powder diffraction, such as figure 1 As shown; SEM, TEM electron microscope inspection product morphology: nanospheres with a size of ~200 nanometers, electron diffraction of a single ball proves that the product has a tendency to become a single crystal, such as figure 2 , 3 shown. The obtained cuprous oxide is dispersed in ethanol to form an orange sol, which is dropped on a silicon wafer or conductive glass to form a self-assembled form in a close-packed form, such as Figure 4 shown. Put the obtained cu...

Embodiment 2

[0034] Embodiment two: get 0.1g analysis pure copper acetate (Cu(CH 3 COO) 2 .H 2 O) Place in a 100ml three-necked flask, add 20ml N, N dimethylformamide to dissolve, add 0.055g PVP (molecular weight 1300000), stir to dissolve, then add 0.14g potassium borohydride, then heat to 90°C in an oil bath or water bath ℃, after 4 minutes, the color changed to orange-red, and the orange powder was obtained by centrifugation. The product was identified as cubic cuprous oxide by X-ray powder diffraction; SEM and TEM electron microscopes detected the product appearance: nanospheres with a size of ~250 nanometers, and the electron diffraction of a single ball was the same as in Example 1. Put the obtained cuprous oxide powder in a porcelain boat, then put it in a muffle furnace, and heat it at a rate of 500°C / hour to 300°C in an air atmosphere for 2 hours to obtain copper oxide nanospheres; X-ray powder diffraction identified it as monoclinic copper oxide; scanning electron microscopy s...

Embodiment 3

[0035] Embodiment three: get 0.24g analysis pure copper nitrate (Cu(NO 3 ) 2.3H 2 O) Place in a 100ml three-necked flask, add 20ml of absolute ethanol to dissolve, add 0.111g of PVP (molecular weight 30000), stir to dissolve, add 0.01g of potassium borohydride, then heat to 70°C in an oil bath or water bath for 5 minutes After that, the color changed to orange-red, and the orange powder was obtained by centrifugation. The product was identified as cubic phase cuprous oxide by X-ray powder diffraction; SEM and TEM electron microscopes detected the product appearance: hollow nanospheres with a size of ~250 nanometers. Put the obtained cuprous oxide powder in a porcelain boat, then put it in a muffle furnace, and heat it at a rate of 500°C / hour to 400°C in an air atmosphere for 2 hours to obtain copper oxide nanospheres; X-ray powder diffraction identified it as monoclinic copper oxide; scanning electron microscopy showed that the size of the nanospheres did not change substan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com