Electrode transfer film,electrode manufacture method using the film and manufacture method of plasma display panel

A manufacturing method and display panel technology, which are applied in the direction of AC plasma display panels, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of high price and high cost, and achieve the effects of simple process, cost reduction, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

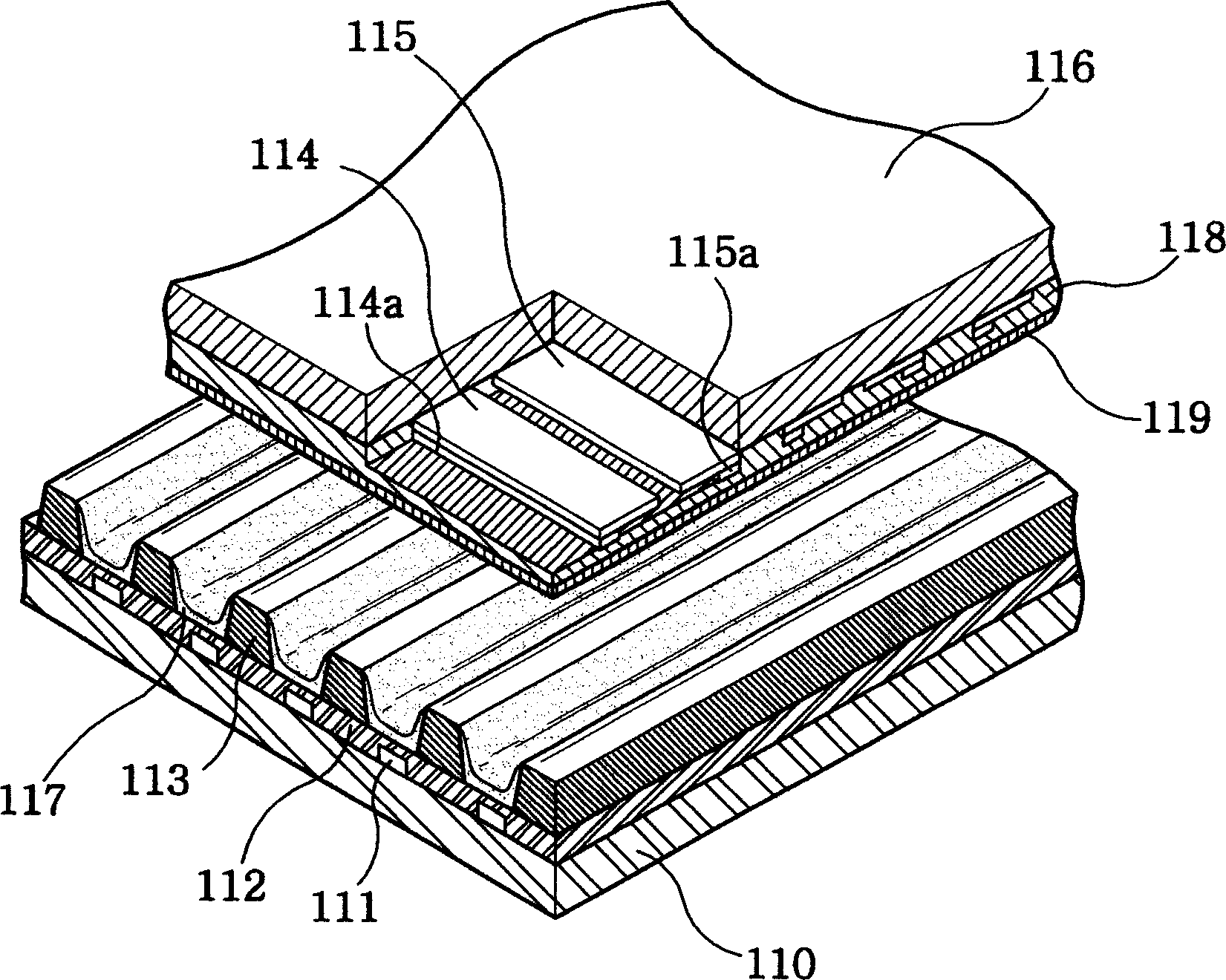

[0033] Hereinafter, preferred embodiments are given, and the plasma display panel of the present invention is described in detail in conjunction with the accompanying drawings.

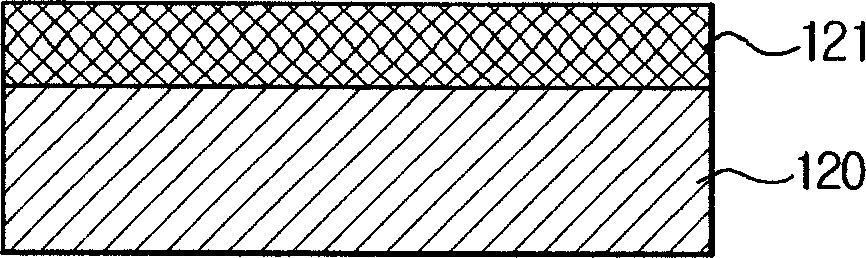

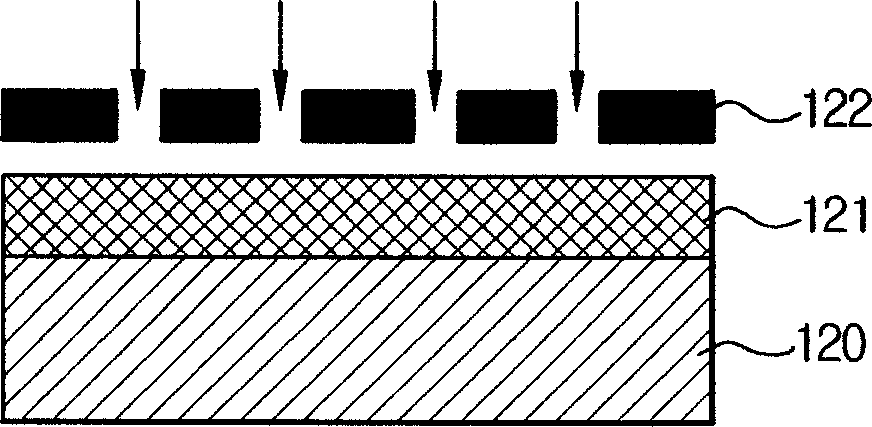

[0034] image 3 It is a sectional view of the electrode transfer film 20 in the embodiment of the present invention. As shown in the figure, it includes: a base film (base film) 21 , a light-to-heat conversion layer 22 formed on the lower end of the above-mentioned base film (base film) 21 , and an electrode material layer 23 formed on the lower end of the above-mentioned light-to-heat conversion layer 22 . Although not shown, a radiation layer may be included between the above-mentioned light-to-heat conversion layer 22 and the electrode material layer 23 .

[0035] The electrode transfer film 20 in the embodiment of the present invention is irradiated with an energy source such as laser light on the part corresponding to the electrode formation circuit, and the irradiated energy source is converted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com