Organic electroluminescent display, and prepartion method

A luminescent and display technology, applied in the field of organic electroluminescent display, can solve the problems affecting the luminous brightness of light-emitting devices, the difference of current value, the uneven luminous brightness of the display, etc., achieve the improvement of display brightness and display uniformity, and broad application prospects , The effect of reducing the column lead resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

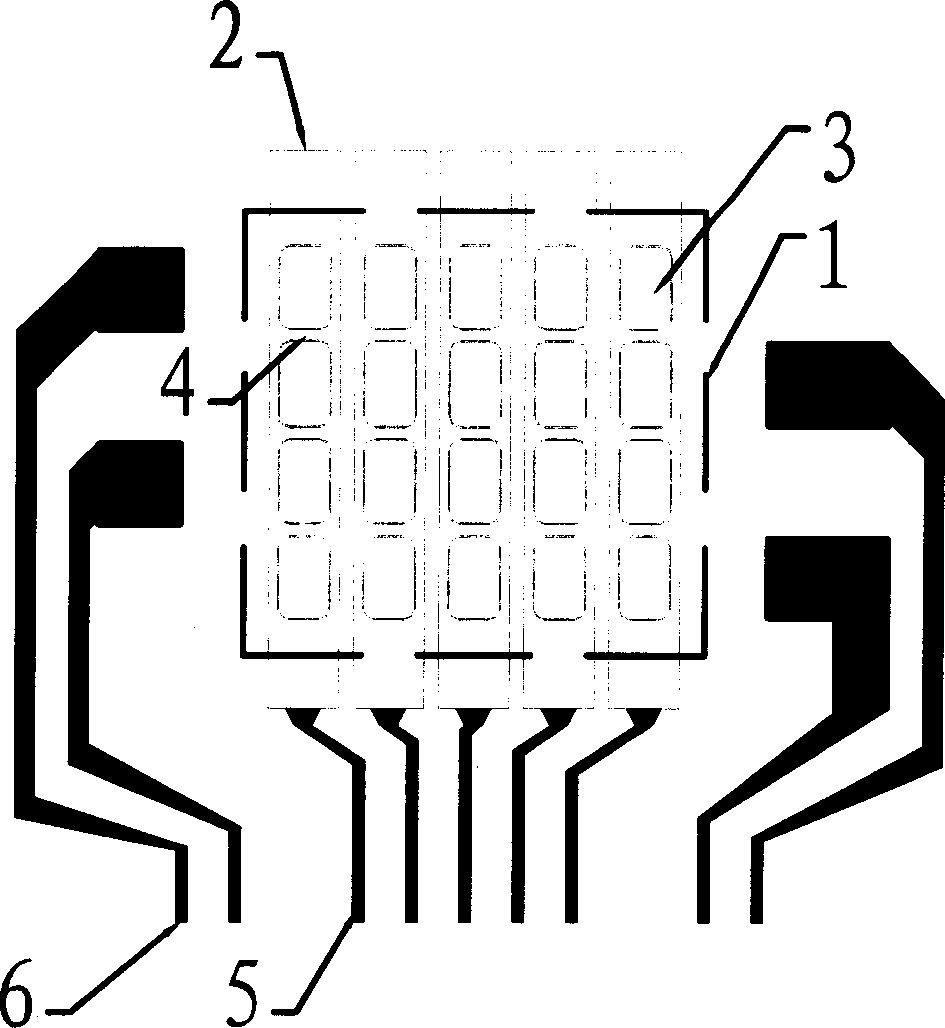

[0042] figure 2 Preparation process of the auxiliary electrode shown. (The preparation process is carried out in the purification workshop). The glass substrate is cleaned with UV irradiation and lotion containing surfactant in sequence. A layer of ITO is sputtered on the cleaned glass substrate to form a transparent electrode. The resistance of the transparent electrode is 15Ω. The ITO film thickness is 170nm, and a layer of metal chromium is sputtered on the cleaned ITO substrate with a thickness of 100-200nm. Make a mask so that the pattern obtained by exposure of the mask includes all the patterns in the gap area 4 except the light-emitting pixels 3 on the first electrode 2 in the light-emitting region 1 and the patterns of the transparent electrode leads 5 and 6 outside the light-emitting region. Apply the photosensitive adhesive evenly on the chromium metal layer on the surface of the glass substrate, put the photosensitive adhesive coated glass substrate into a high-t...

Embodiment 2

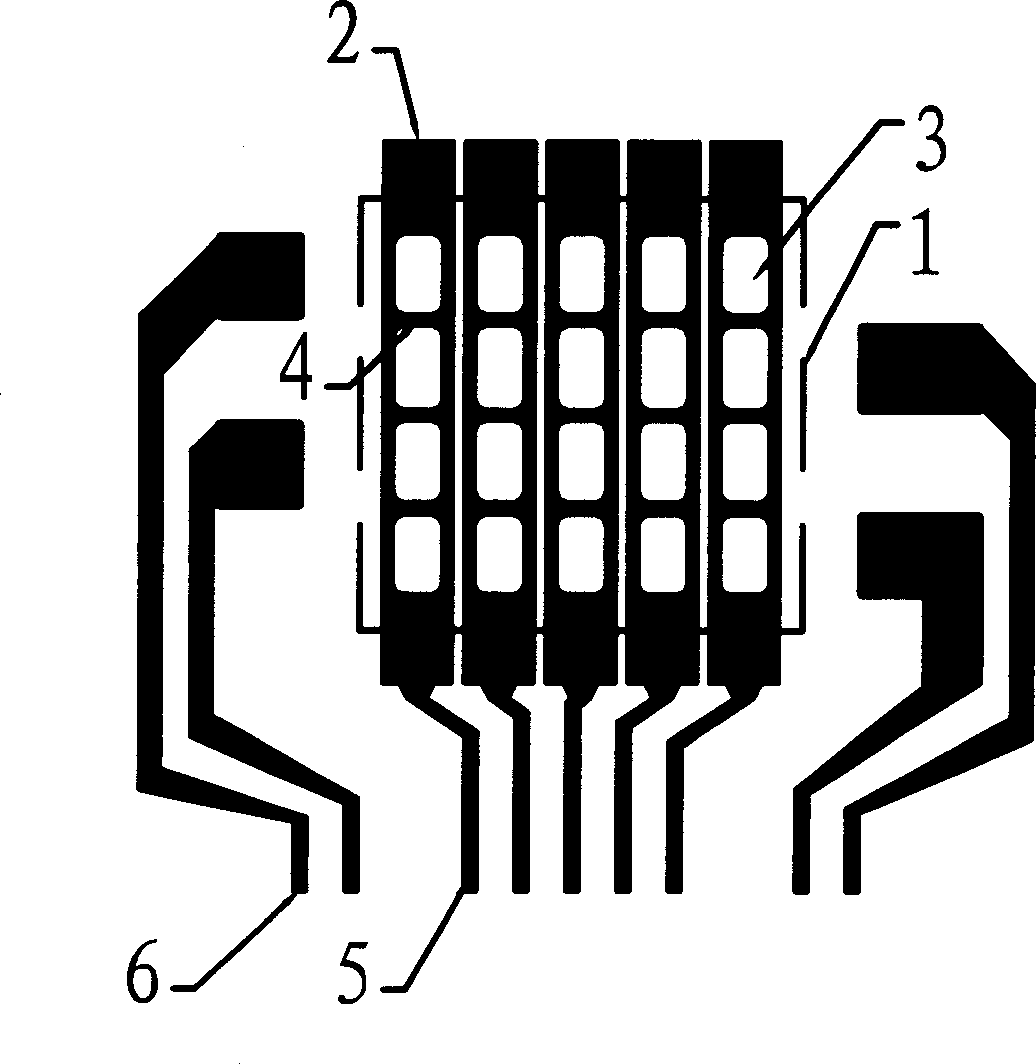

[0044] image 3 The preparation process of the shown auxiliary electrode, the specific operation process is the same as that of Example 1, the difference lies in the making of the mask plate and the selection of aluminum as the low-resistance metal, image 3 The mask plate made in the process, so that the exposed pattern of the mask plate includes the light-emitting pixel gap area 4 pattern spaced on the transparent electrode 2 in the light-emitting area 1 and the transparent electrode lead wires 5 and 6 patterns outside the light-emitting area, and finally made The auxiliary electrode pattern such as image 3 shown.

Embodiment 3

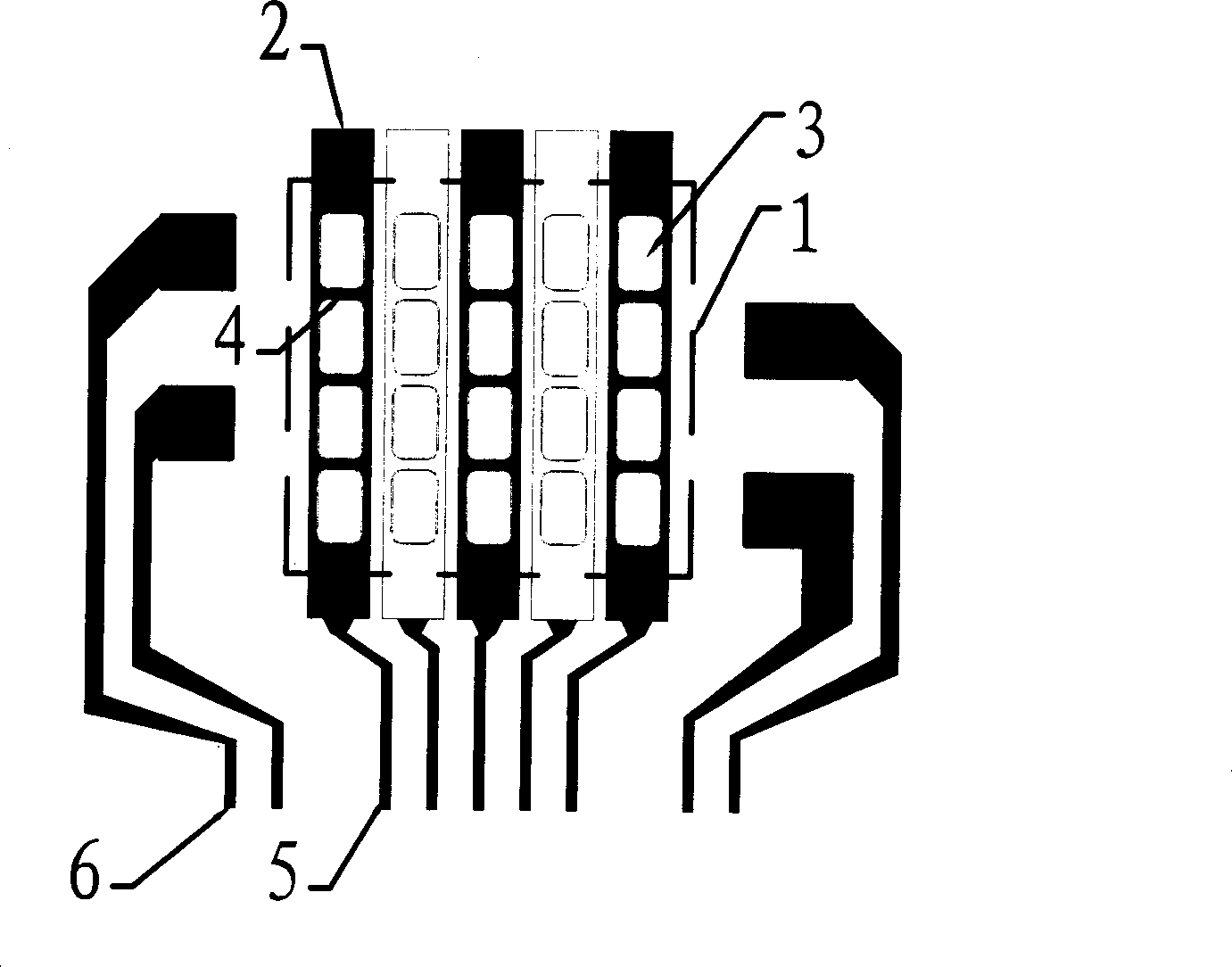

[0046] Figure 4 In the preparation process of the organic electroluminescent display shown in Example 1, on the basis of the auxiliary electrode obtained in Example 1, the pattern transfer and etching of the ITO electrode are carried out, and a group of parallel and separated straight lines are photoetched. Spin-coat a layer of photosensitive organic insulating material, which can be photosensitive PI, positive novolac photoresist, negative cyclized rubber, etc. In this embodiment, photosensitive PI is selected, exposed before baking, and the exposure pattern is mesh structure (only the light-emitting area of the device pixel and the lead connection area are exposed) or a strip structure (a group of parallel and separated straight lines perpendicular to the transparent electrode pattern), the width of the line is determined by the display resolution. Determined by the spacing between pixels, the line width is 10-50um. The above-mentioned exposed organic insulating layer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com