Slender water fog jet with double-ring surface crack nozzle

A fine water mist and torus technology, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of high cost, complex structure, and low flow rate, and achieve the effects of good atomization performance, large spray flow rate, and less water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

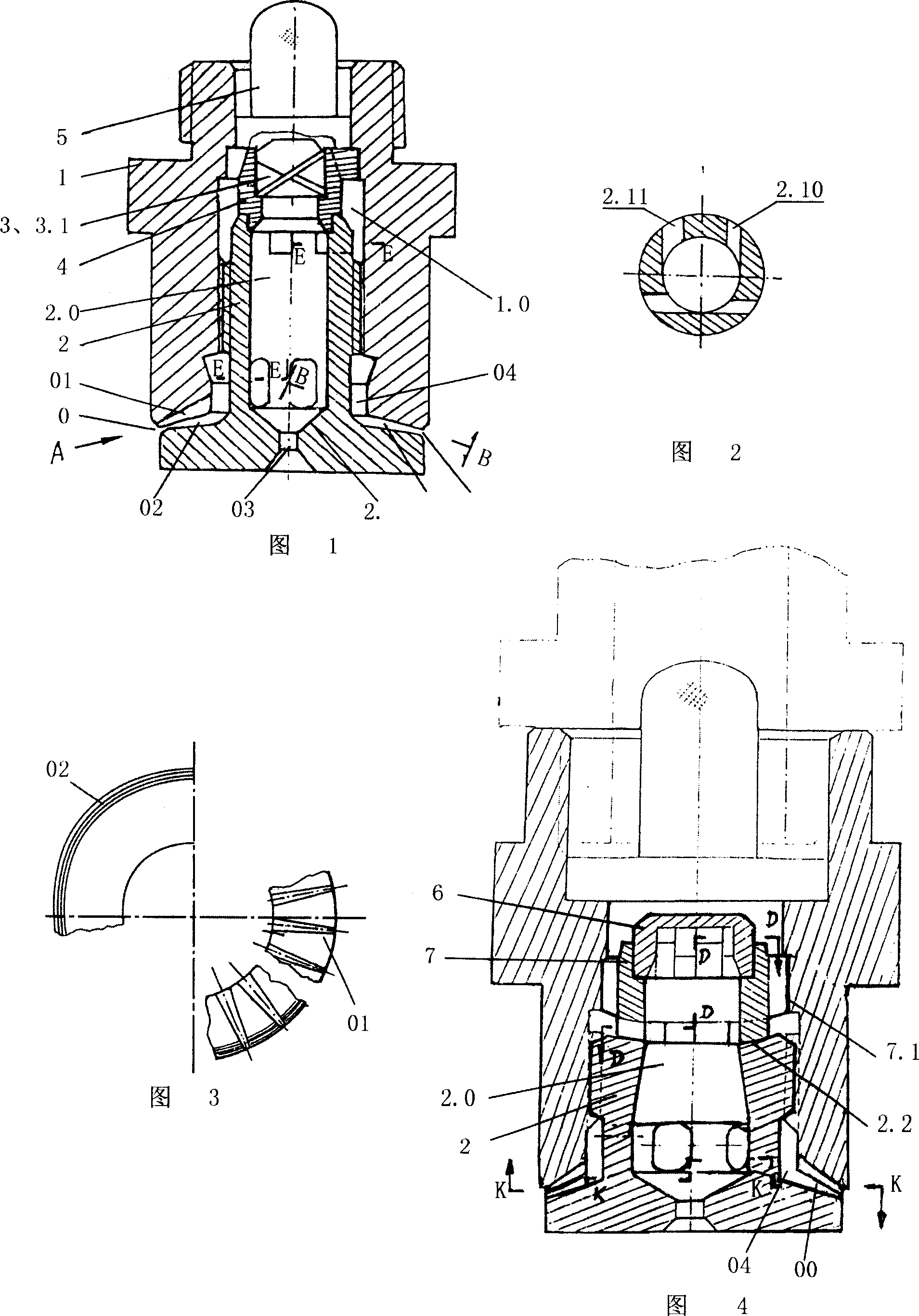

[0071] Embodiment 1: the open-type fine water mist nozzle of band double-annular crack nozzle and vortex device, swirler.

[0072] Referring to Figures 1 to 3, the inner cavity 1.0 of the nozzle seat 1 with the filter 5 is provided with a stepped cup-shaped nozzle body 2, the nozzle body inlet is equipped with a vortex seat 4, and the outer cylinder of the vortex seat seals the central cavity 2.0 of the nozzle body The tangential groove 2.10 on the entrance of the cavity wall, the outer thread of the nozzle is inserted and screwed into the inner cavity 1.0 of the nozzle holder. The vortex 3 with the vortex core 3.1 and the tangential groove 2.10 on the inlet of the nozzle body cavity constitute a two-stage series-parallel structure of the vortex and the cyclone of the nozzle body, and the outlet of the cyclone is connected to the center cavity 2.0 of the nozzle body. The central cavity of the large diameter end of the nozzle body shrinks into a cone hole (called the nozzle bod...

Embodiment 2

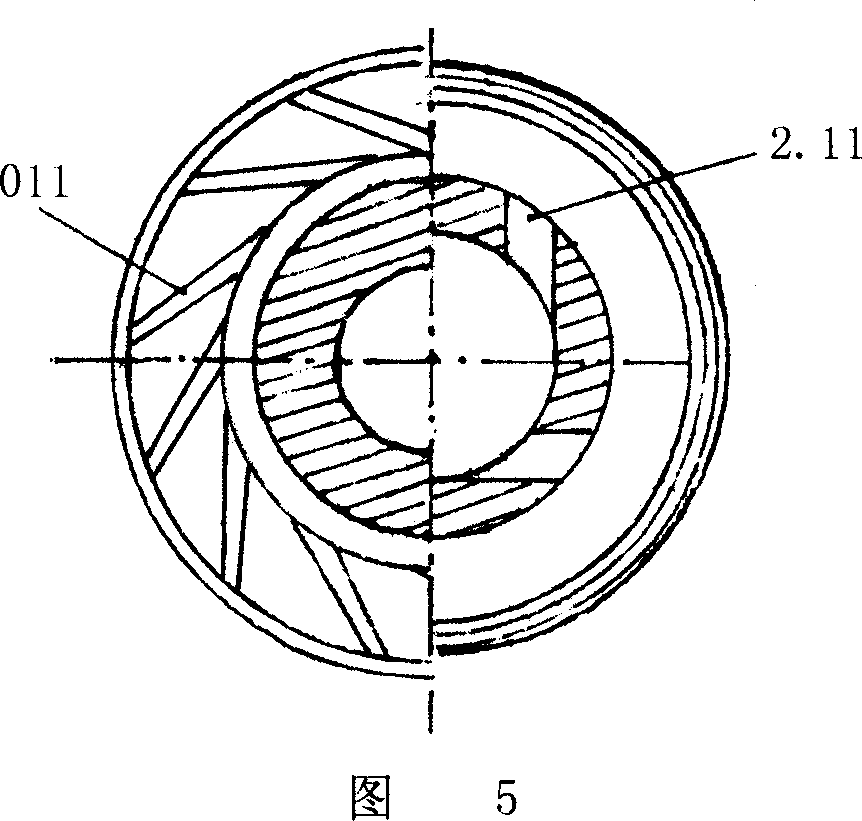

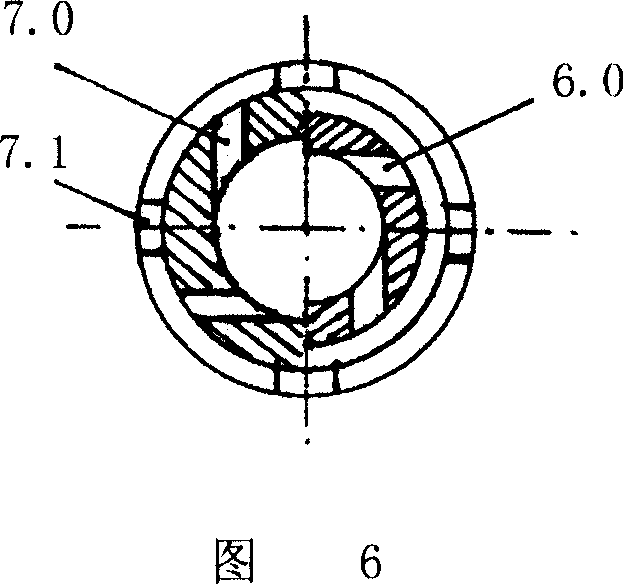

[0074] Embodiment 2: an open-type fine water mist nozzle with a double-annular slit nozzle and a two-stage cyclone.

[0075] See Figures 4-6. As shown in FIG. 4 , a stepped cup-shaped nozzle body 2 is arranged in the cavity of the nozzle seat with a filter. The entrance of the central cavity 2.0 of the nozzle body is provided with a primary cyclone 6, and the cap-shaped cyclone with a tangential groove 6.0 is set in the cyclone seat 7. The bottom of the cyclone seat is provided with a tangential groove 7.0 of the cyclone seat, and the top inclined surface of the tangential groove 7.0 of the cyclone seat coincides with the top cone surface 2.2 of the body cavity wall of the nozzle and is pressed against the top cone surface of the body cavity wall of the nozzle. The bottom of the device seat and the top cone of the nozzle body cavity wall together form a two-stage cyclone, and each inlet of the two-stage cyclone communicates with the inlet of the inner cavity of the nozzle sea...

Embodiment 3

[0076] Embodiment 3: the open-type fine water mist nozzle with double-annular slot nozzle, vortex device and spiral channel.

[0077] Referring to Figures 7 and 8, the structure shown in Figure 8 is basically the same as that of Embodiment 1, and the same parts will not be described again. The entrance of the body cavity of the nozzle is formed; the difference is that there is no tangential oblique hole on the wall of the body cavity of the nozzle in embodiment 3, but a spiral through groove 2.3; Shape, which is provided with a ring sheet 14 with a circle of reed whistle vibrator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com