Nickel radical battery and its anode

A battery, nickel-based technology, applied in the field of nickel-based batteries and their positive electrodes, can solve the problems of decreased production efficiency, hindered substrate transmission, small surface area, etc., to achieve the effects of improving production efficiency, reducing short-circuit rate, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

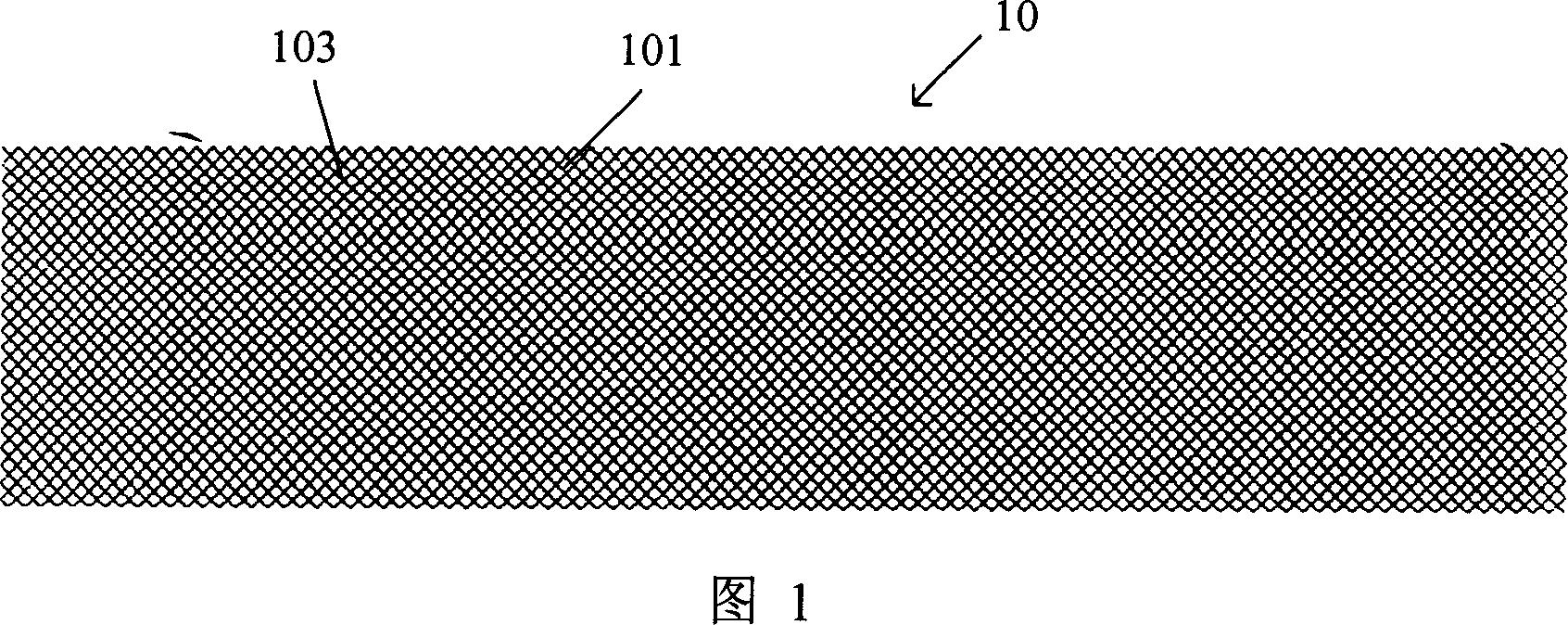

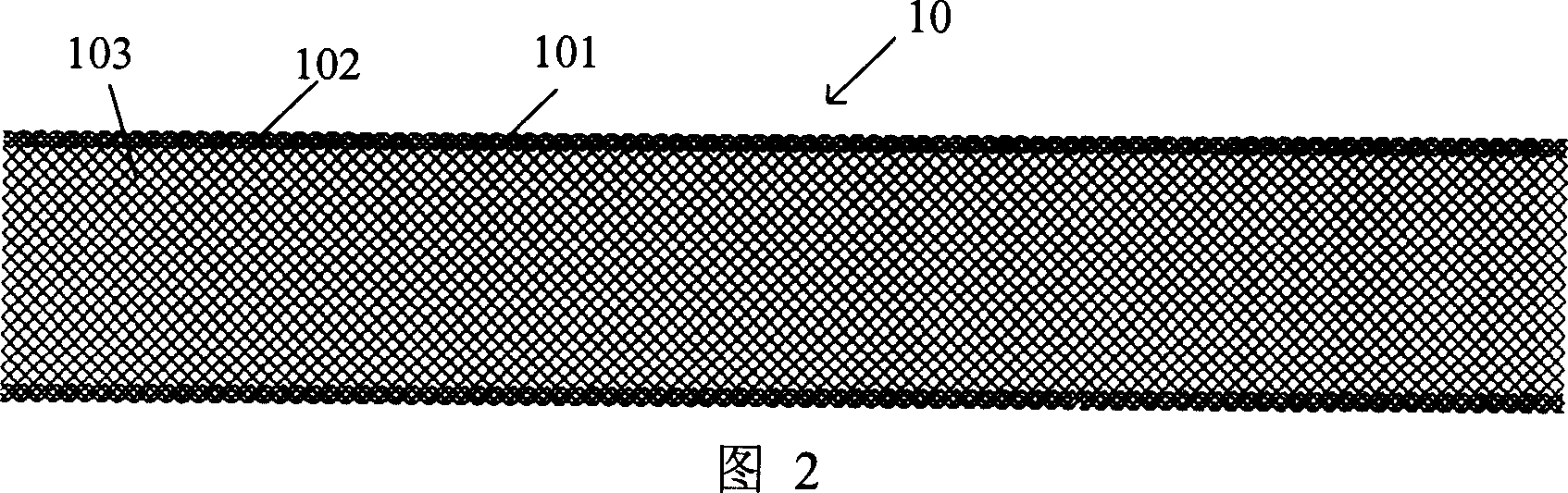

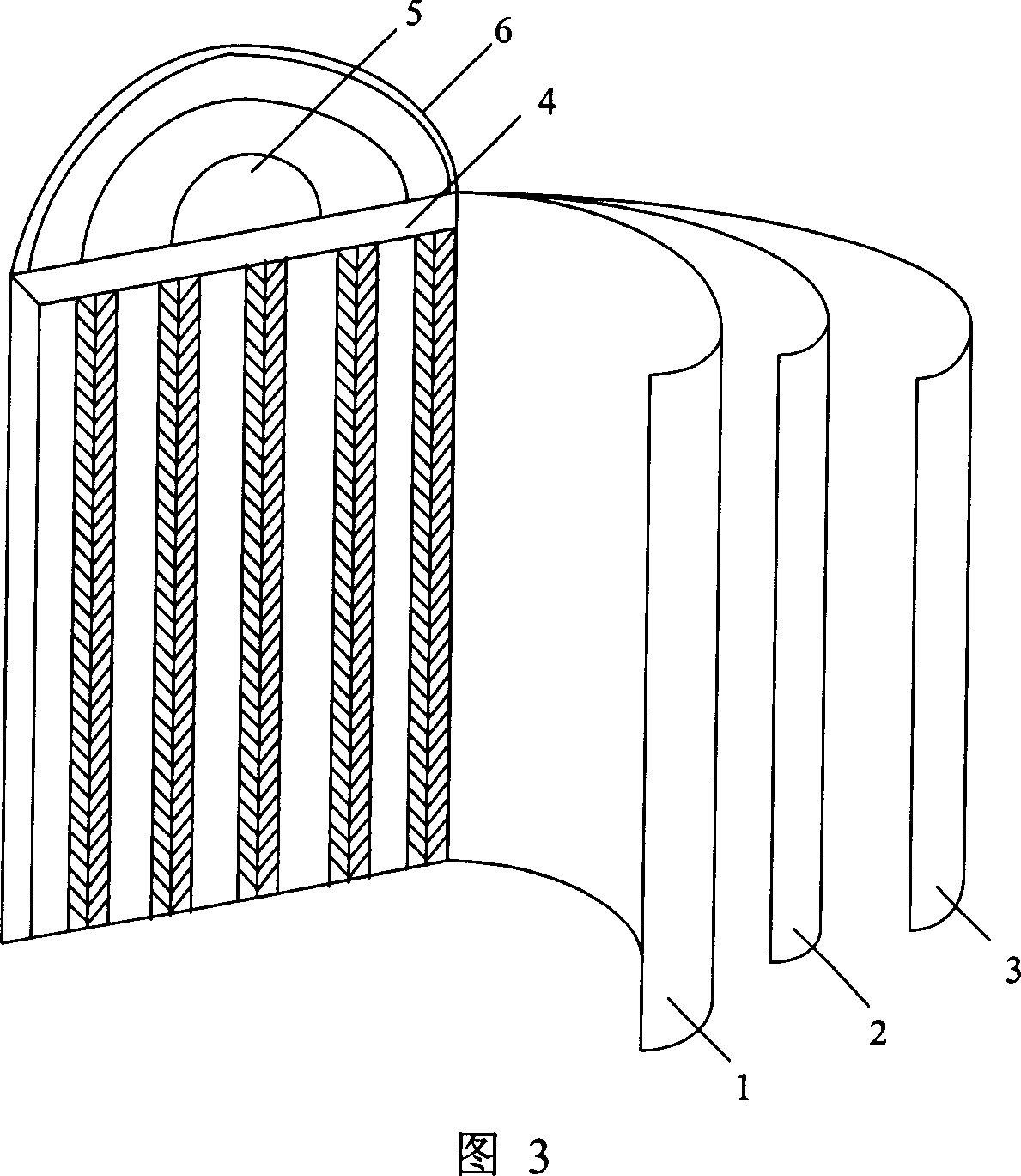

[0016] The invention provides an electrode of a nickel-based battery, which is composed of a hem-cut net and an active material filled therein, a conductive material and an adhesive, and the active material and the conductive material are fixed on the hem by the adhesive Chela net 10 on.

[0017] Wherein, as shown in FIG. 2 , the hemming cutting net is used to manufacture the skeleton of the positive electrode. Its main body is a mesh metal substrate 101, and its side is bent inward to form a flat hemming 102. The hemming 102 can be Fold the jagged burrs protruding from the edge of the substrate 101 to the inside. There are several cutouts 103 distributed on the substrate 101. The cutouts 103 can be stretched into diamond-shaped, square, circular or fan-shaped holes as required. At the same time, the pieces around the cutouts The material twists as it is pulled and forms the border of each hole.

[0018] In one embodiment of the present invention, the metal mesh is a steel sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com