Device for performing surface treatment on pole piece of lithium battery

A surface treatment device, lithium battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of not increasing the output, short-circuiting the cells, puncturing the diaphragm, etc., to improve the quality of the pole pieces, and reduce the short-circuit rate. , high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

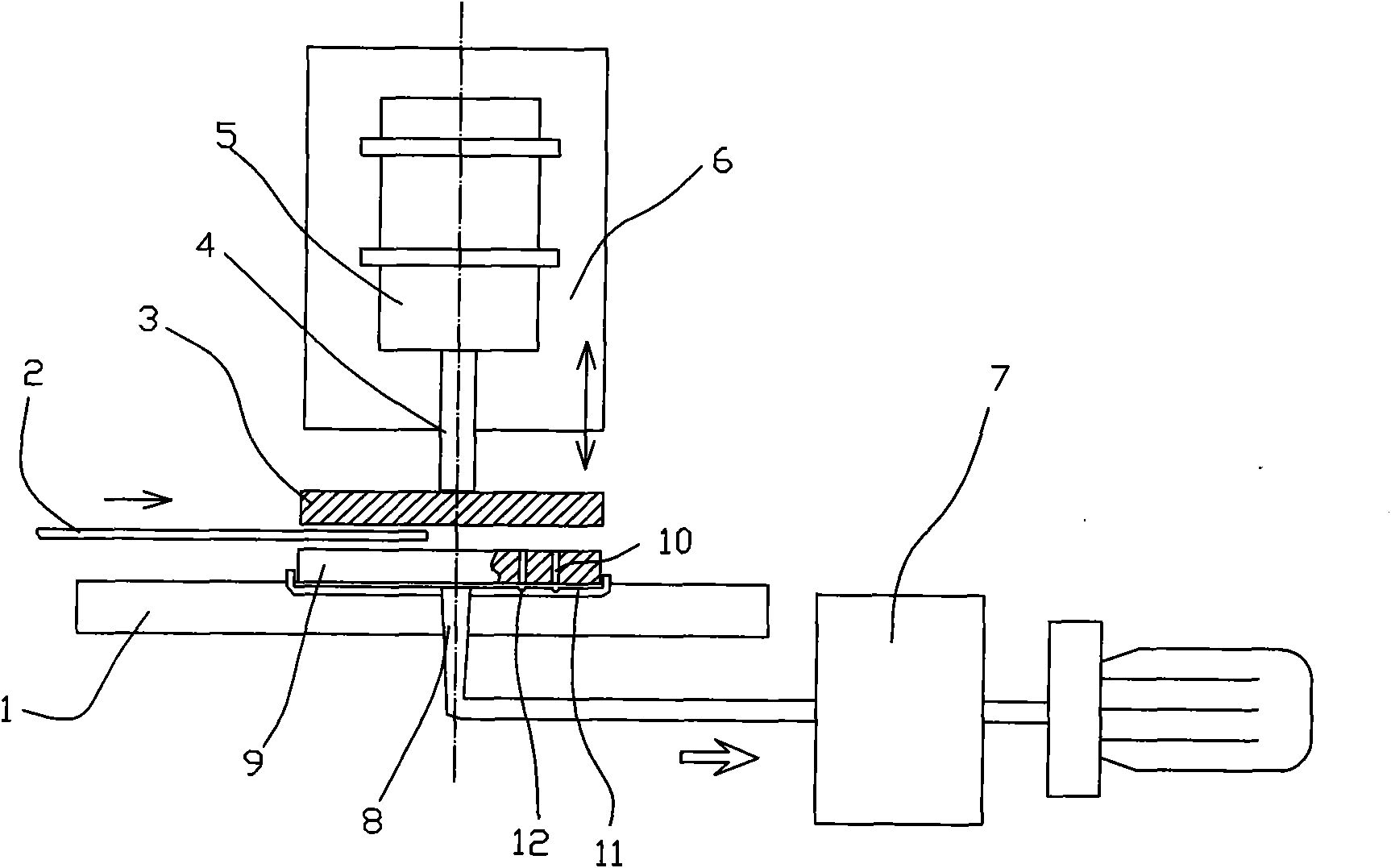

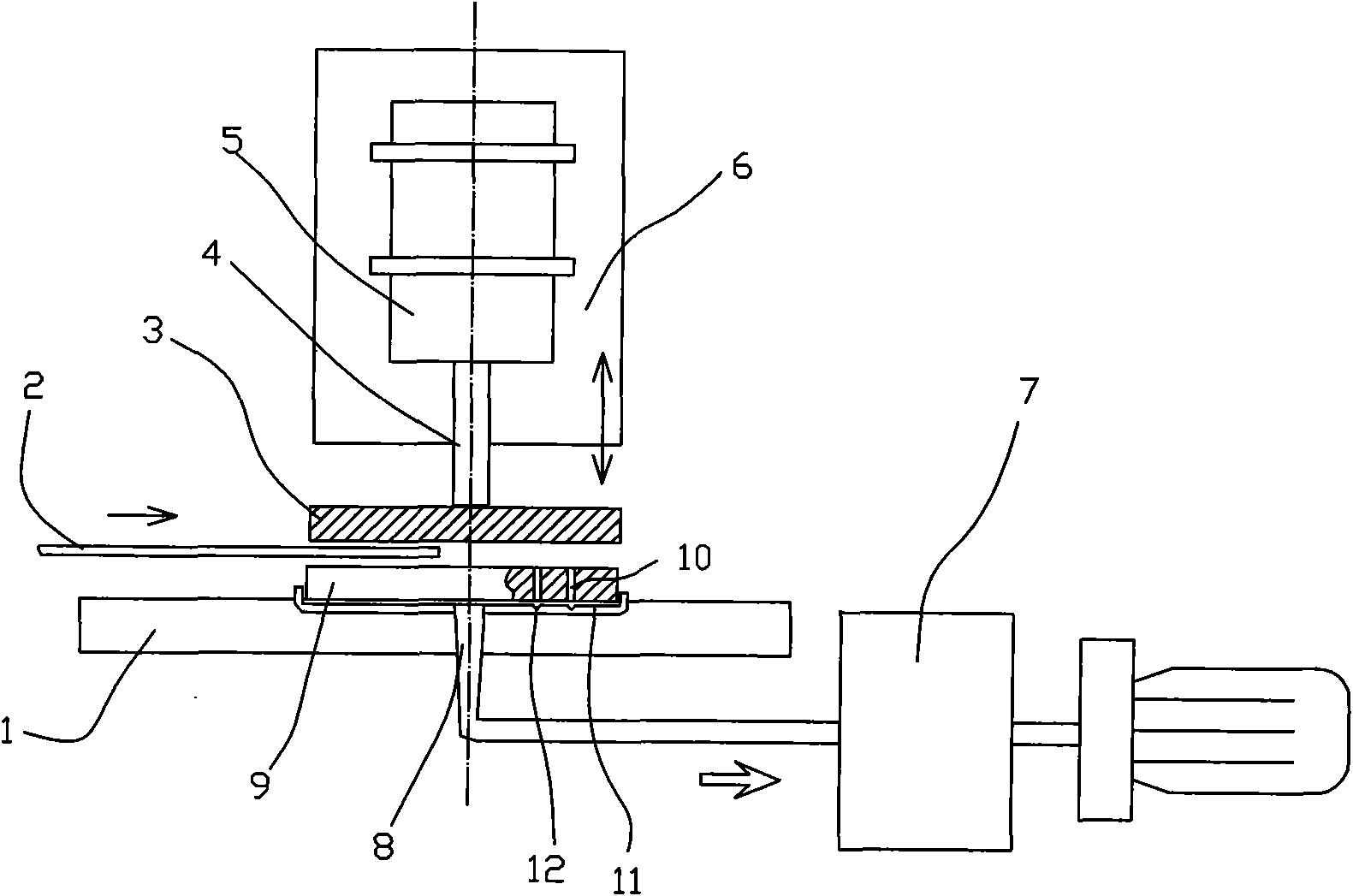

[0012] The present invention as figure 1 Shown, comprise frame 6, workbench 1, also comprise upper sponge 3, lower sponge 9, negative pressure device and upper sponge drive cylinder 5; Described lower sponge 9 is fixedly arranged on workbench 1; Described upper sponge drives The cylinder 5 is arranged on the frame 6, and the piston rod 4 of the upper sponge drive cylinder 5 faces downward, and the bottom end of the piston rod 4 is fixedly connected to the upper sponge 3, and the upper sponge 3 is positioned above the lower sponge 9; The negative pressure device includes an air compressor and a suction pipe 8 (the dust storage tank 7 is installed in the negative pressure pipeline to prevent secondary pollution), the suction pipe 8 runs upward from the bottom of the workbench 1, and the mouth of the suction pipe 8 is located in the Lower sponge 9 inside.

[0013] A tray 11 for supporting the lower sponge 9 is provided on the lower part of the lower sponge 9 , and a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com