Switch plug for wire terminal

A technology of wire terminals and plugs, which is applied to the parts of the connection device, the manufacture of contacts, and electrical components, etc., and can solve the problems that the second plug 22 is easy to fall off, high-frequency vibration, and urgent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe in detail the relative positions and functions of the various components of the present invention, the following preferred embodiments are listed and described below with accompanying drawings.

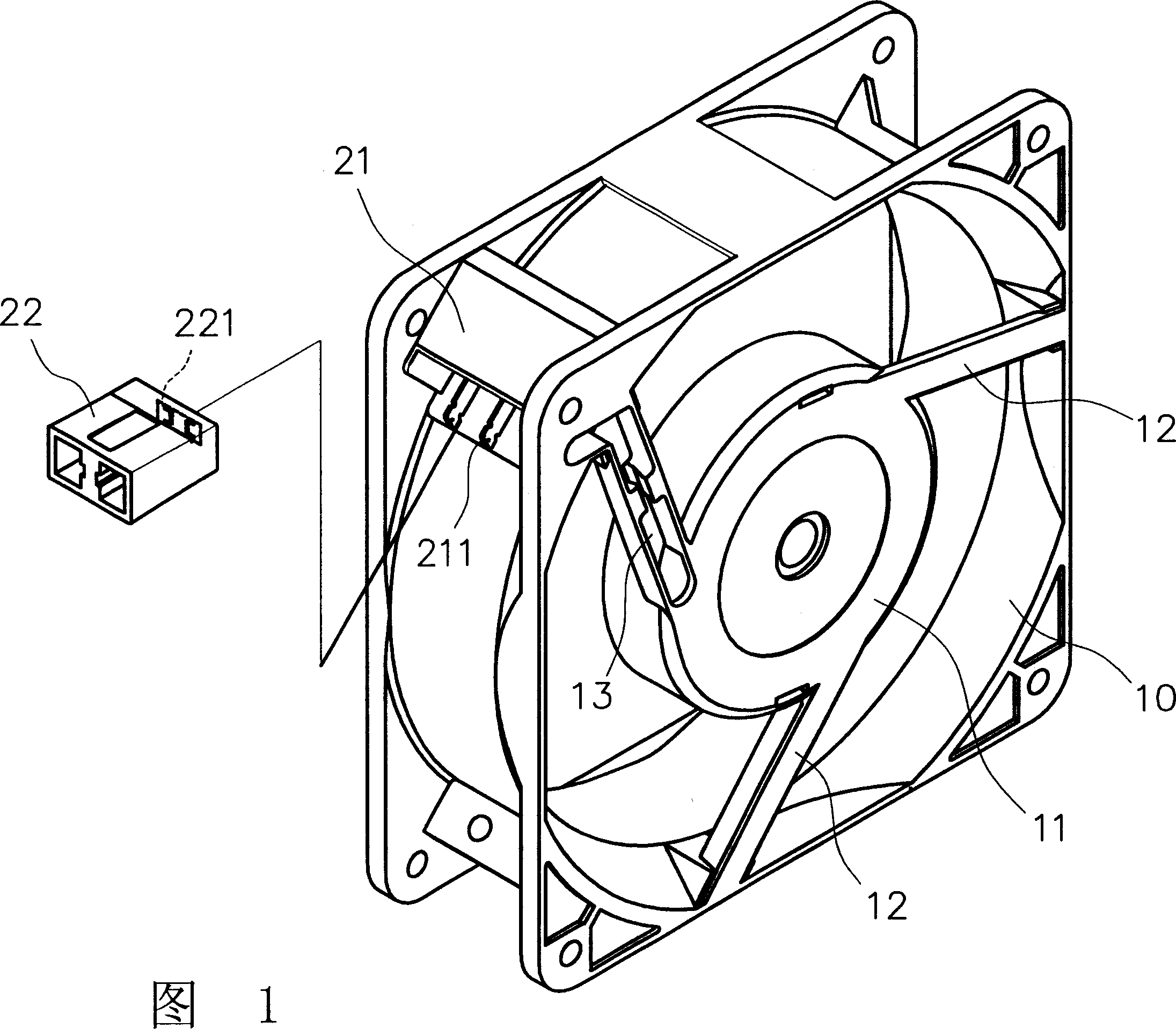

[0028] A wire terminal plug provided by the present invention is used on the frame body 10 of various heat dissipation system equipment. As shown in FIG. A motor stator and a motor rotor can be installed and positioned. The motor base 11 and the frame body 10 are connected by a plurality of ribs 12, and one of the ribs 12 is provided with a wire groove 13, and the wires connected to the motor stator are along the wire groove. 13 protrudes, and a terminal is provided at the position where the wire groove 13 is connected to the frame body 10 .

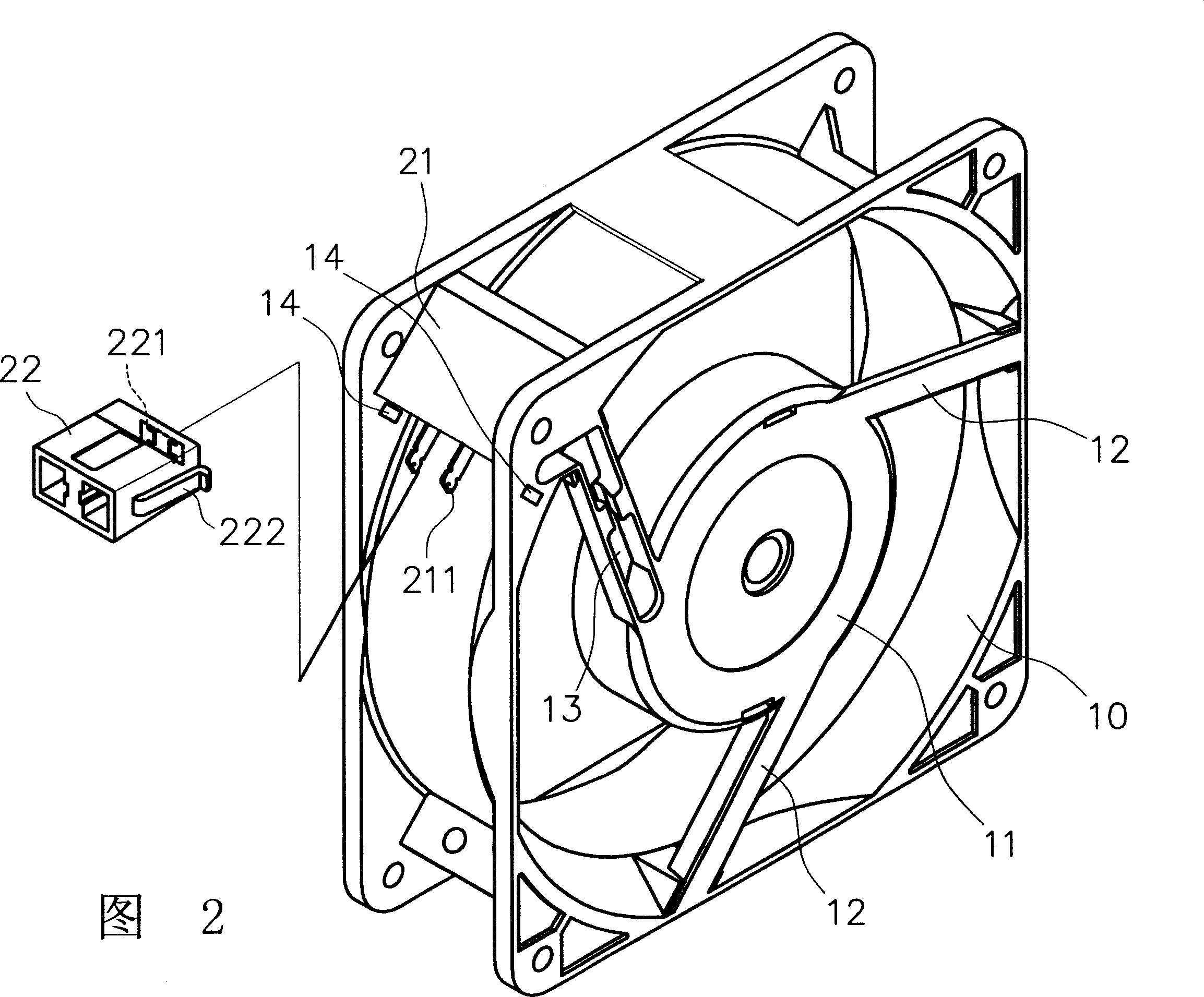

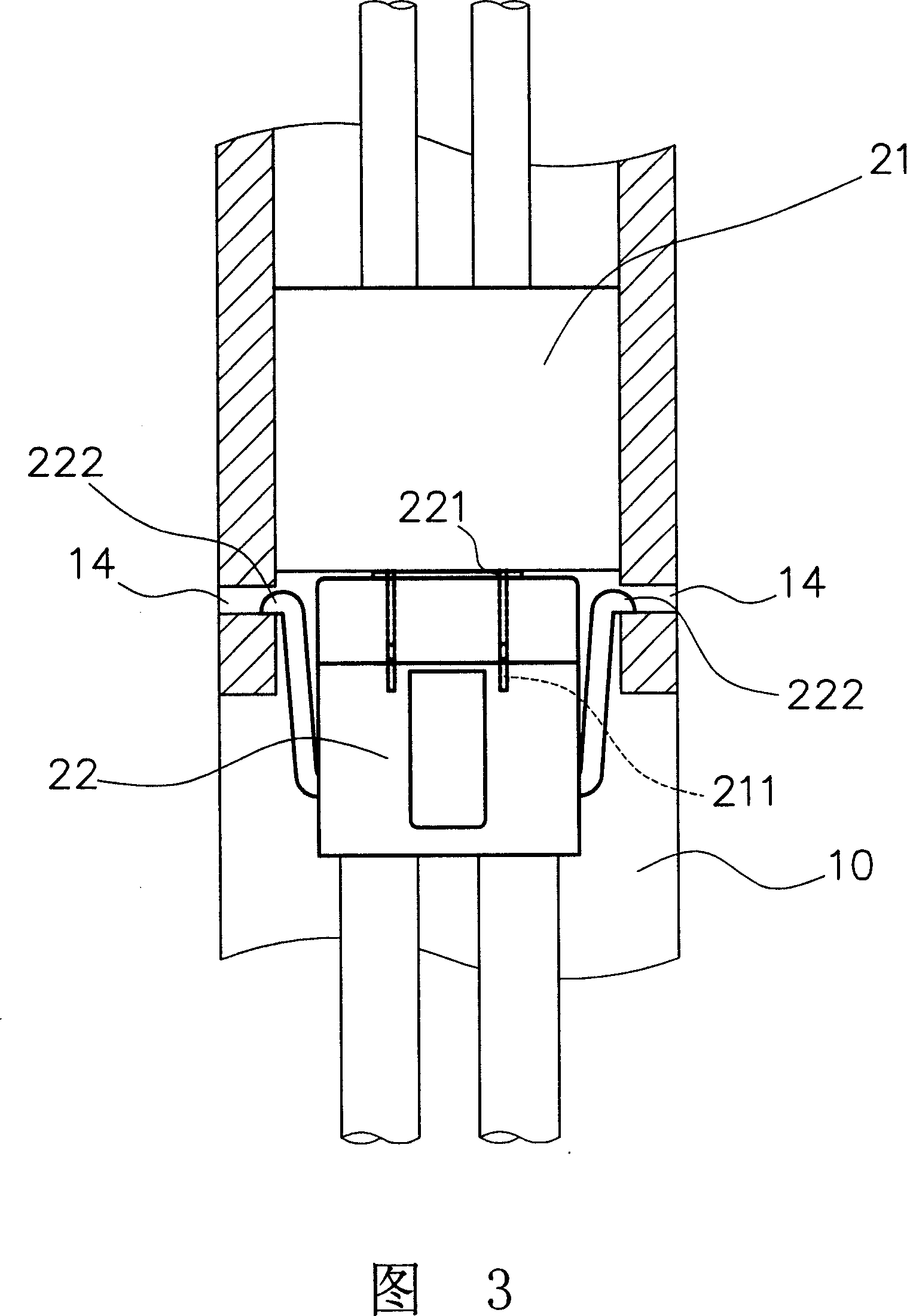

[0029] As shown in Figure 2 and Figure 3, the terminal includes a first plug 21 and a second plug 22, the first plug 21 is connected and fixed with the wire connected to the motor stator, and one end has a pin 211, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com