Self-adjusting electric power mechanism suite

A self-adjusting and kitting technology, applied in the field of electric power, can solve the problems of no way to deal with external fire, short circuit of power components, poor heat dissipation effect, etc., to improve the ability of self-protection, reduce the probability of fire, and be easy to replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

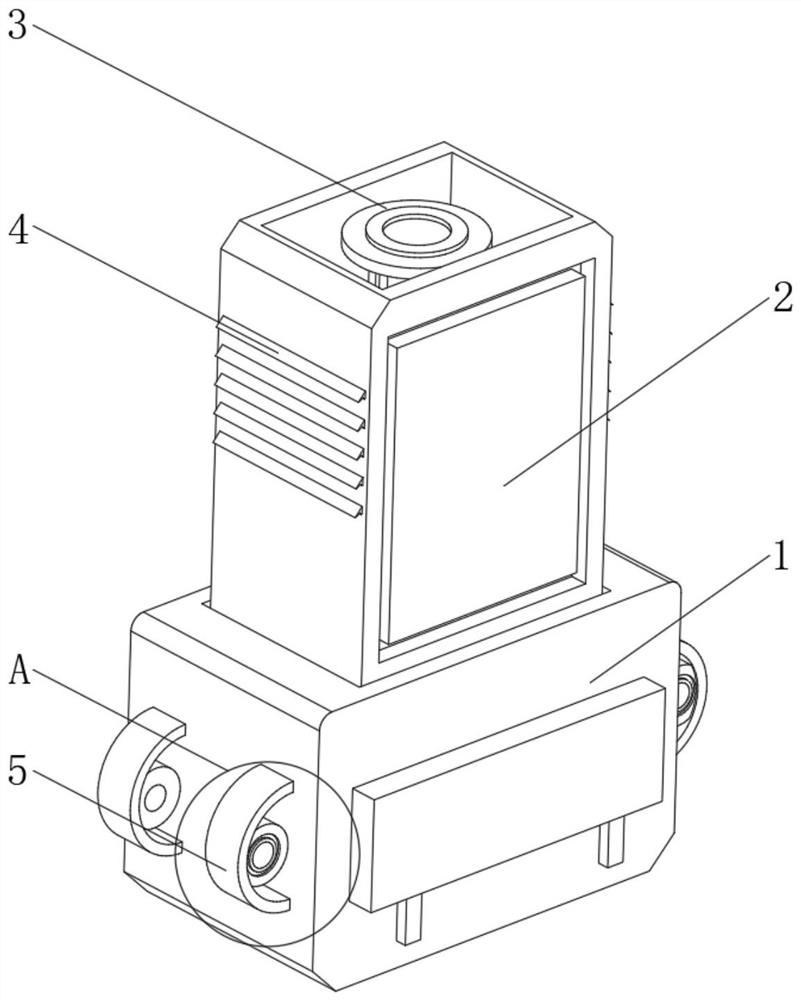

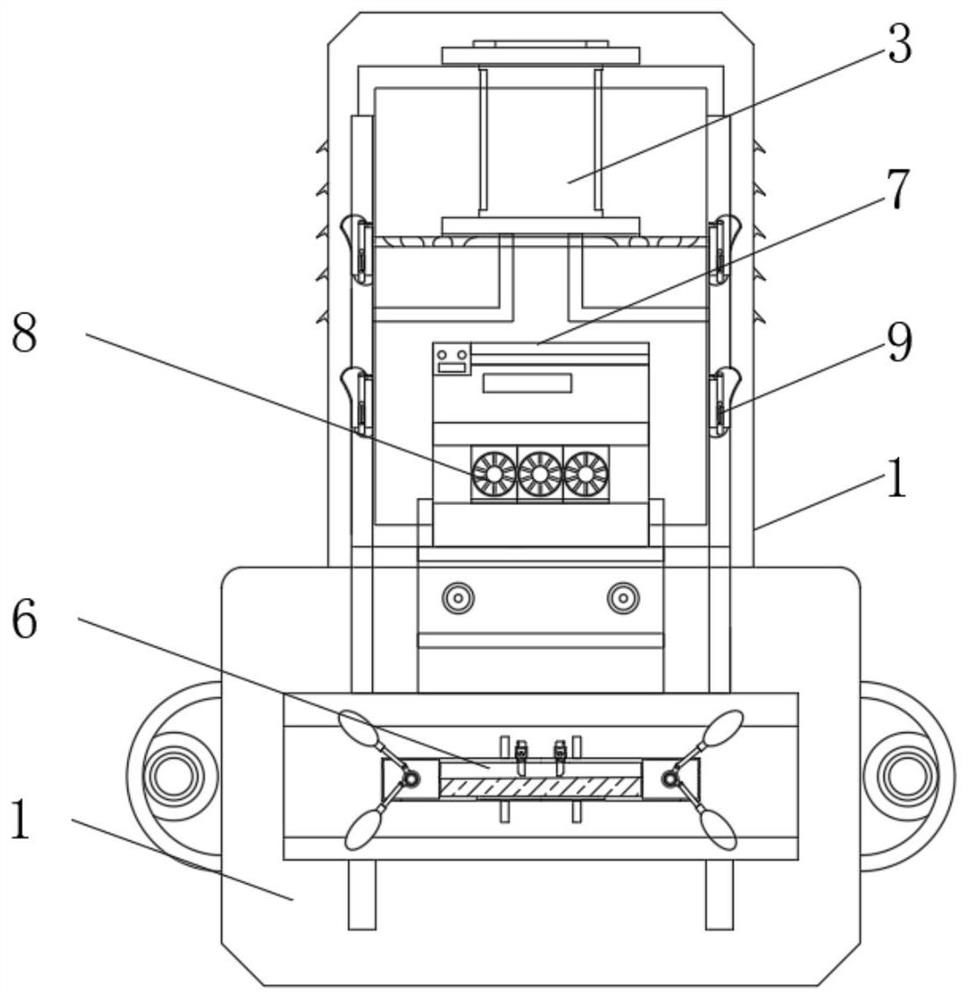

[0033] see Figure 1-4 , the present invention provides a technical solution: a self-regulating power mechanism kit, specifically including,

[0034] Kit base 1, the kit base 1 has an inner cavity mounting base body, and an inner cavity for installing the kit;

[0035] Kit body 2, the kit body 2 has an installation box, and a docking seat 3 installed above the kit body 2, a docking cavity is opened in the middle of the docking seat 3, and a spring buckle is arranged inside the docking cavity, and the side of the kit body 2 A heat dissipation grid 4 is provided to facilitate the installation of the top kit inside the docking seat 3, and the spring docking buckle can ensure the positioning and fixing of the device;

[0036] Exhaust device 9, this exhaust device 9 has adjustment mechanism, and is installed on the installation buckle frame of kit main body 2 sides, kit main body 2 internal heat dissipation mechanism suite 7, and heat dissipation mechanism suite 7 is equipped with...

Embodiment example 2

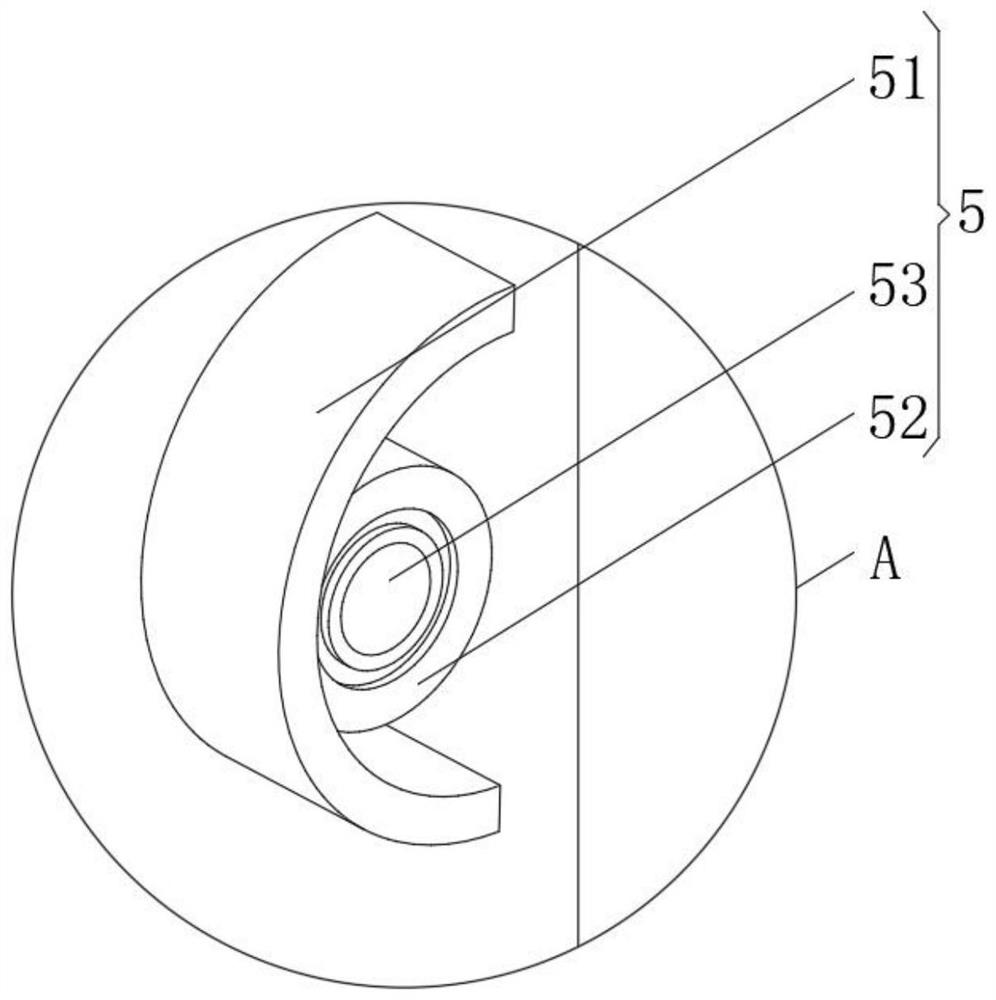

[0042] On the basis of implementing Case 1, please refer to Figure 5-6 , the present invention provides a technical solution: the emergency heat dissipation device 6 includes an integral component box 61 and an external heat conduction sheet 66, the integral component box 61 is installed above the external heat conduction sheet 66, and heat conduction seats 62 are arranged at both ends of the integral component box 61 to conduct heat The outer side of the seat 62 is equipped with an elliptical extended heat conduction sheet 64 through a heat conduction pipe 63, and the elliptical extended heat conduction sheet 64 is arranged above the outer connection heat conduction sheet 66, and a heat conduction gasket is arranged between the outer connection heat conduction sheet 66 and the outer connection heat conduction sheet 66, which can The heat inside the power kit is conducted to the larger external heat conducting fins 66 to increase the heat dissipation area and improve heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com